What is the clothing sample?

Developing a clothing sample involves deciding on the required results beforehand. A clothing sample is created according to these specifications and sent from the manufacturer to the designer. This unique product includes fabrics, descriptions, zippers, buttons, ingredients, sizes, quantities, appearances, color specifications, product styles, embroidery details, reference numbers etc. Clothing samples link those who produce garments and those who purchase them。

Prototype samples, sales or sales representative samples, fitted samples, size samples, pre-production or production samples, shipping samples, denim sample photo displays etc., are all types of clothing samples.

Is it worth making garment samples before production?

Is it necessary to create clothing samples before mass production? You must evaluate your product against others on the market and see if yours stands out. If you want to know what you will sell, you can order clothing samples from a manufacturer. They are typically low-quality items that give designers an idea of sizing and proportions.

Before a clothing company finalizes and produces its garments en masse, they create prototypes–multiple versions of the same product to test which features work best. By doing this, businesses can decrease how much wasted material there is from failed attempts. Sampling different styles help find what customers want but also creates more waste than if mass-produced items were improved incrementally over time.

People have become more conscientious of late regarding fashion wastage. In fact, the fashion industry produces 40 times the waste that consumers do. Only 15% is recycled and reused; 85% is dumped or burned in local landfills. To avoid contributing to this problem, there are alternatives.

The importance of clothing samples

It is crucial to have clothing samples for any designer. A designer may request multiple samples from different vendors so they can compare the products together. This process allows designers to ask for changes before going into production.

The best way to guarantee the quality of your design is to create a sample. By giving the vendor a prototype beforehand, you can micro-manage the production process and ensure that mass production meets your high standards.

Various clothing samples

Mock up

A mock-up is the first interpretation of a designer’s concept. Sometimes, this idea doesn’t translate as well on paper as on fabric, and that’s where a mock-up comes in handy. It doesn’t require embellishments; its sole purpose is to test whether the garment is feasible. Not every design needs a mock-up, so not every designer or factory uses this type of sample. In some cases, a tech pack or sketches are enough to convey the idea.

But for complex designs, a mock-up can give you a better sense of how the garment will look and feel once it’s completed. It can also highlight any potential construction issues that must be addressed before moving forward with production. Whether you’re working on your own designs or overseeing a team, it’s important to understand mock-ups’ role in the fashion design process.

Prototype or development samples

A prototype or development sample is the first sample made during the production cycle. The factory follows the original sketch or technical package provided by the designer. This idea only reviews the style and design aesthetics, so it does not need to be built according to full specifications.

Any weight-similar fabric and decoration can be used, depending on its availability. Generally, three prototype samples are made: two for brand/designer reference and one for factory reference. The prototypes are usually made of similar materials as the production samples, but the colors and trims may not be exactly the same. These prototypes help ensure everyone is on the same page regarding style and design details before moving into full production.

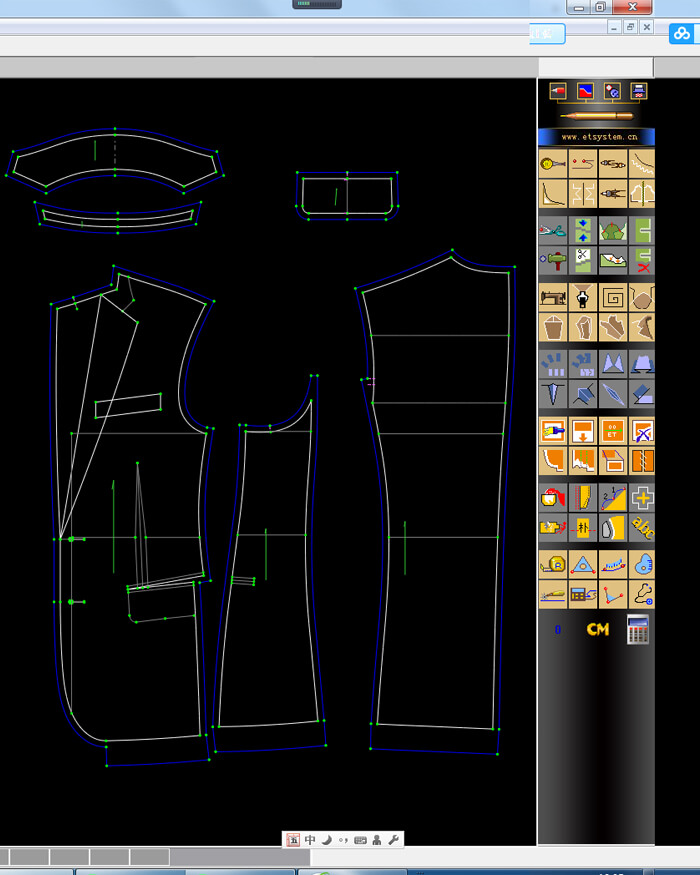

Digital clothing samples

3D digital samples are a software-rendered 3D clothing form, allowing for the visualization of fit and drape in static and motion. While the steep learning curve and high implementation costs may be limiting factors for this technology, if brands can overcome these obstacles, 3D can significantly reduce the cost of sample production and the time needed for approval between designers and factories.

In addition, 3D digital samples can be used to create virtual showrooms and fit sessions, reducing the need for physical samples. As technology continues to evolve, it has the potential to completely revolutionize the way clothing is designed and produced.

Fit Samples

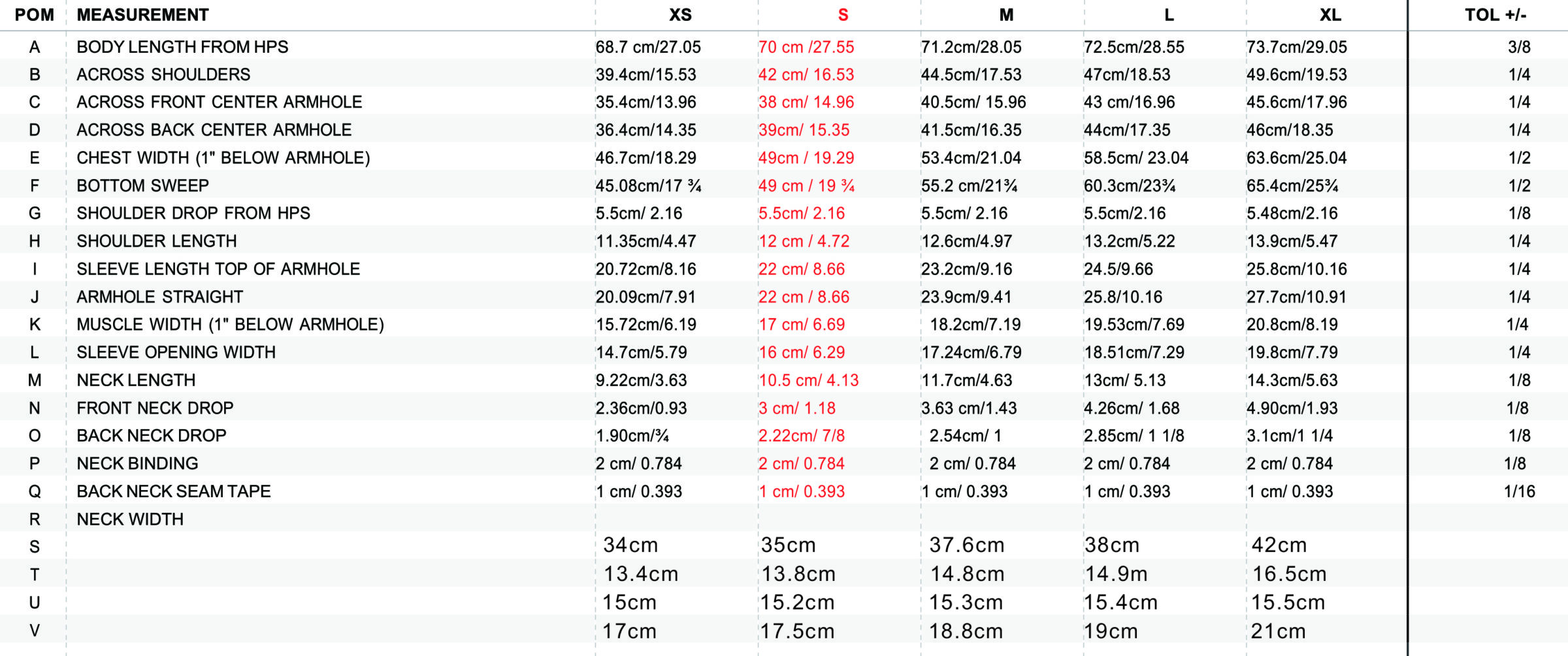

To ensure a garment looks good on customers of different sizes and properly hangs, we create fit samples. To pass inspection, all measurements and construction details must be accurate.

To achieve the desired fit, a sample can be made from a similar fabric as the final design. You will need to make multiple adjustments at this stage and add the sample size to your tech pack.

Size set sample

After approving a size set sample, you grade the basic pattern for each size to generate a 3-sample of product from the final materials. These “size sets” help ensure success in bulk production by getting an accurate preview of the end result. Your tech pack should always include specifications for your entire intended size range.

Salesman sample

Salesman samples (SMS) are products used for marketing and promoting a range of other products. They consist of approved final fabric and finishes in base sizes that are generally exhibited in retail stores or trade fairs, helping generate orders from their respective retail channels. SMS also provides merchandisers insight into the product while engaged in range planning.

When customers use augmented reality, they not only save time and money but also see what the product would look like in real life. This is due to consumers viewing a 3D image of the product rather than just a photo or drawing, which wouldn’t give justice to how it looks.

Not only should outgoing SMS be beautiful, but they should also act as company ambassadors. If a potential customer sees a well-made sample, it will help them envision the final product — instilling confidence and prompting an order.

On the other hand, if a sample is badly made, it could have a knock-on effect on orders being placed as customers lose faith that what they will receive will be up to standard.

GPT sample

Testing provides data essential to making an informed decision about whether or not to produce a style. GPT samples are “garment performance tests” that allow brands to put a garment through extensive testing, such as seam strength and slippage, colorfastness, washing fastness, etc.

Additional considerations may be made after taking all test results into account.

Report results from independent testing laboratories help brands determine whether garments will meet quality and performance standards, thus bypassing common production problems. Cut down on time wasted by implementing this strategy in your business.

Pre-production sample

A pre-production sample is a garment clothing sample manufacturers use to prove a pattern. If you want to evaluate mass production feasibility, estimate costs or assess price range, you can order a pre-production sample. Your design’s recognized form is the last step before starting mass production.

To avoid any unwanted surprises, your pre-production sample must include all of your design’s components and construction details. This way, you can review and approve the sample before going into production. Otherwise, you run the risk of making changes that are costly and time-consuming to fix later on.

You must work with a reliable sample maker with expertise in your industry and product category. This way, you can avoid any potential delays or problems down the road. An accurate pre-production sample will help ensure a smooth transition into mass production.

Sealed sample

Once PP samples are approved, they are sealed at manufacture to standardize mass production and prevent tampering. Depending on the brand’s level of approval, these types of samples may also be referred to as gold stamping or red stamping samples.

Most brands use gold stamps to symbolize approval, while others may brandish red stamps for disapproval. If a sample is turned down by a factory, it’s typically sent back to the design team for more changes before being submitted once again for approval.

While it may take a few weeks or months to get a sample approved, depending on the brand, you can produce items in mass quickly and without much hassle, once it is finally approved.

TOP (Top of production) sample

After a PP sample is approved, production can commence, and the brand’s quality control inspectors can visit the factory whenever they please to select a garment from the production line for inspection. These samples are referred to as “top of production samples” or “TOP” and are examined for quality assurance to ensure that mass production has consistent quality as the PP sample. The packaging of TOP samples is also checked.

Shipment sample

The factory will set aside some samples as shipping samples after the mass production is completed and the shipment is ready. Brands use these samples to test the final product that consumers will see, testing everything from folding to packing. Approval for shipment only comes after the sample has passed this test. If any part of the sample fails, it gets sent back to the factory for improvement before being retested. By going through this approval process, we can guarantee that the products shipped meet—and exceed—the standards set by the brand.

Press samples

A press sample replicates the final product, usually made in model size. They are used for shooting publicity materials such as advertising campaigns, lookbooks, and e-commerce and can be lent to magazines for editorial shoots. If a product is not ready to be released to the public, a press sample may be made to meet deadlines.

For example, if a fashion designer needs images of their garments for a magazine’s spring issue, but the collection will not be ready to ship until summer, they may send press samples instead. Although slightly different from the final product, press samples are an essential tool for marketing and creating hype before a launch.

How to get clothing samples made?

Below are some tips to help you find and hold onto a good clothing manufacturer when starting your own business. These makers will teach you what skills and techniques you need and what materials work best for producers. Often, designers have clothing samples manufacturers working with them on long-term projects–so once you’ve found a decent one, don’t let them go!

- Request work samples. This will give you an idea of their quality of work and attention to detail.

- Ask for references from their past and present clients. This will give you an idea of their customer service skills and how they handle clients who are unsatisfied with the final product.

- Get pricing estimates. This will help you budget for your clothing line and ensure that the prices align with what other clothing samples manufacturers are charging for similar services.

- Share your vision. It is important that the manufacturer understands your vision for the clothing line and is willing to work with you to make it a reality.

Wrapping Up

Consumers, retailers, and designers in the fashion industry all rely on clothing samples. You can guarantee a higher quality product by understanding how to identify different types of samples and their purposes. If you want to be sure that your vision for a clothing line is realized, it’s best to work with a reputable manufacturer.

At Lezhou garment, we have years of experience crafting clothing samples. We only use the highest quality materials to manufacture our products and back them with exemplary customer service. If you want to learn more about what we do or how we can help you, please contact us today for more information.