What’s the difference between screen printing and digital printing?

Screen printing

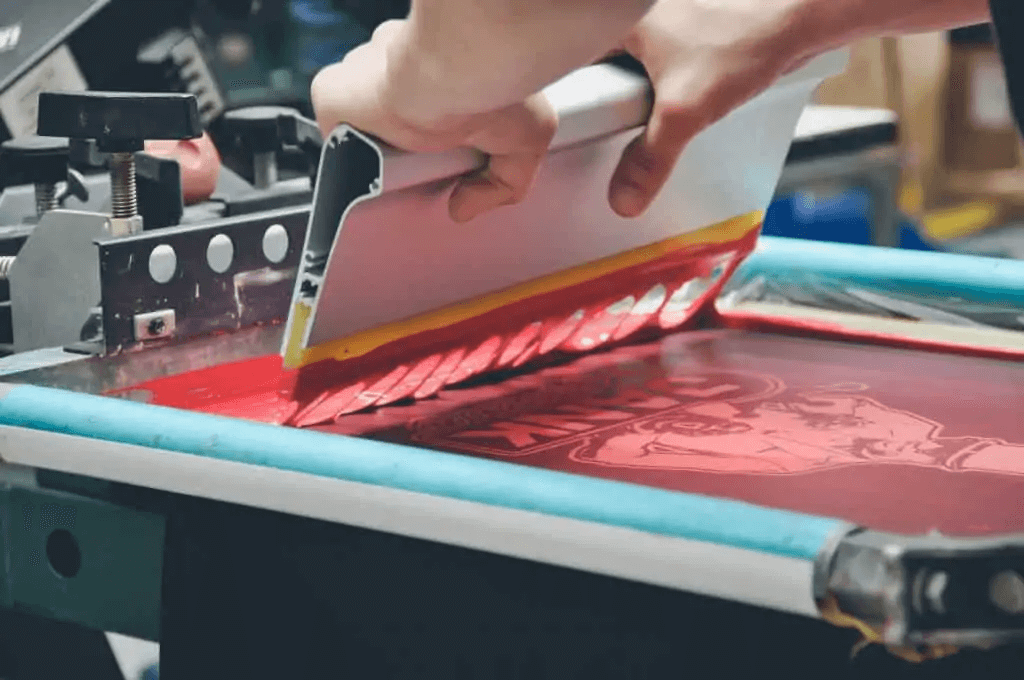

The most common and popular printing method, screen printing, is where plastic inks are passed through a mesh screen and onto the fabric.

Digital textile Printing

Digital textile printing is a cutting-edge technology in which ink is sprayed onto clothing. This method is the quickest and easiest way to print multi-colored designs.

What is silk screening?

Screen printing has been around for centuries, and it is the most commonly used method of garment decoration. This technique pushes different ink colors through separate screens onto the fabric. The ink is then cured with heat to set it in place.

Silk screen printing uses more colors than other printing methods and can produce a three-dimensional effect. Additionally, this type of printing is advantageous because it can be done on different materials such as cotton, synthetic fibers, linen, and natural leather.

Another advantage to silk screening is that it can make three-dimensional images, making items appear more lifelike. The primary downside of this method is how long it takes, as well as the level of skill needed to do it correctly; if not done so, ink might spread or jump.

Despite this, screen printing is still an excellent choice for clothing decoration. Many high-end brands use screen printing to create unique and amazing designs.

Screen printing technology principle

Screen printing is a popular technique in which ink is pushed through a screen onto a substrate. The ink only passes through the areas of the screen that are not blocked by the stencil, resulting in a sharp, clear image. Screen printing is ideal for printing on t-shirts, posters, and other materials.

Although modern machines can print more than 100 t-shirts per hour, the quality of the print job is still largely dependent on the operator’s skill. Despite all the technological advances, each shirt must be manually set up on the screen printing machine. Consequently, screen printing remains a labor-intensive process. But with its high-quality results, it remains a popular choice for businesses and individuals.

In what ways is screen printing better than digital printing?

Screen printing is better suited for:

- Larger orders with a higher volume.

- Large or unusual print areas.

- Logos or text that is printed in a single color.

- Specialty inks with added special effects.

- Printing designs on polyester and other synthetic fabrics.

- Dark fabrics accented with vibrant colors.

- If you need exact color matching.

What is digital printing?

Digital printing is printing from a digital file directly to various media. It is generally reserved for smaller print runs due to its lower initial cost. Compared to traditional methods, such as screen printing or offset printing, digital printing offers some advantages.

First, there is no need for plates or screens, as the image is printed directly onto the substrate. This eliminates the need for costly setup charges.

Additionally, digital printing offers variable data printing, which allows you to customize each print piece with text or images specific to the recipient. This can be an effective way to personalize your message and increase response rates.

Finally, digital printing provides on-demand printing, which means you can print only the number of pieces you need when you need them. This can save time and money by eliminating the need for warehousing and inventory management.

Digital printing working principle

Digital printing is a relatively new technology that has revolutionized the printing industry. Compared to traditional methods, digital printing is faster, more versatile, and more affordable.

Here’s a closer look at the working principle of digital printing:

- First, a digital file is created using Adobe Photoshop or Illustrator software.

- This file is then sent to a printer, which is transferred onto the print media using special inks or toners.

- The process is typically completed within minutes, making digital printing ideal for quick turnaround times.

In what ways is digital printing better than screen printing?

Digital printing is better suited for this.

- Smaller, simpler orders (including single pieces).

- Standard print positions and print sizes.

- 100% cotton prints.

- Designs with lots of detail.

- Gradients and other photographic elements.

- Designs with a wide range of colors and blends.

- When a soft hand or light print is important.

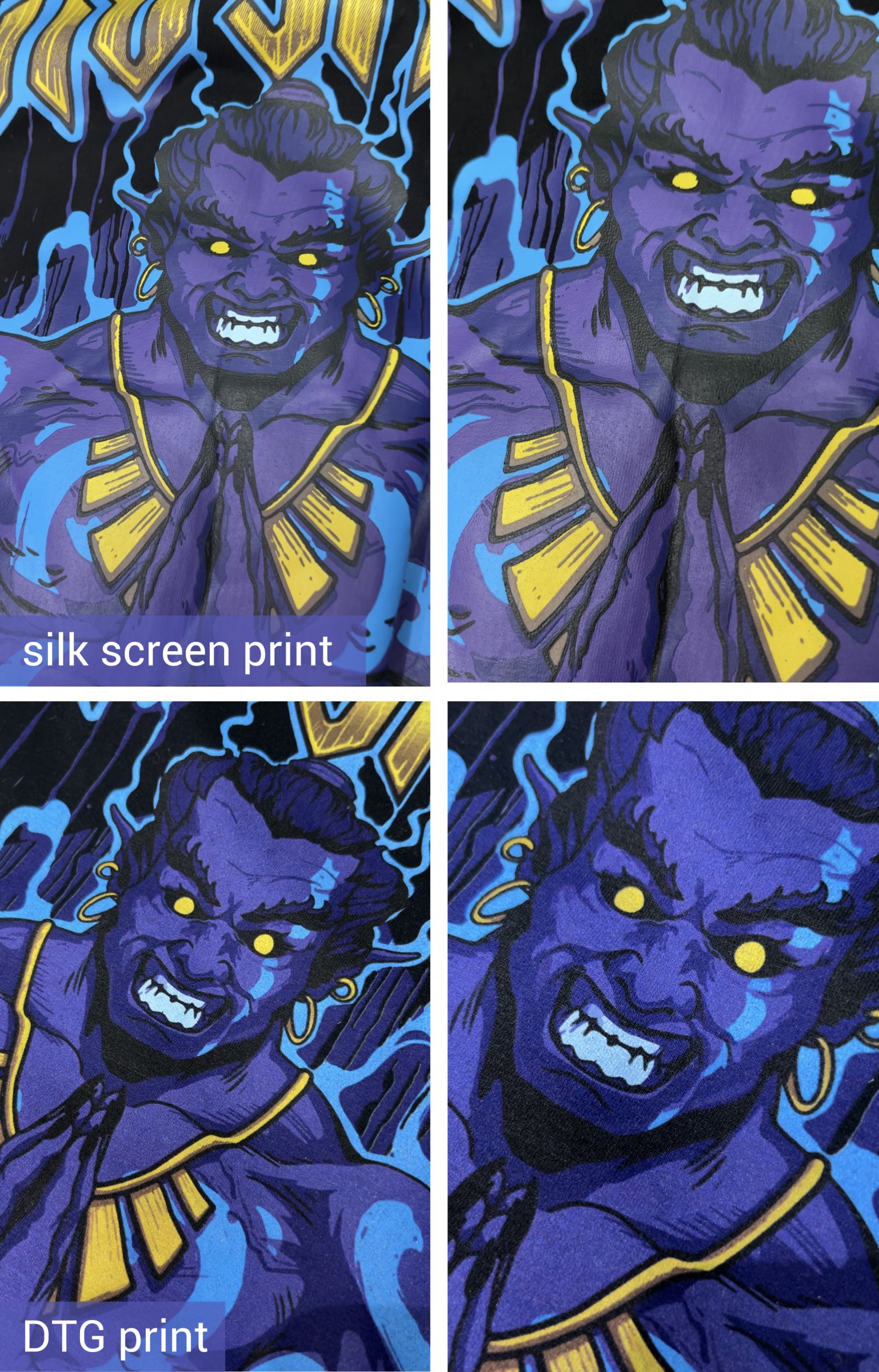

Screen Printing vs. Digital Printing: Vibrancy

When making your designs pop, screen printing is the way to go. Screen printing offers brighter and more vibrant colors than digital printing, giving your designs a more eye-catching look. In addition, screen printing is more resistant to fading and wear, so your designs will last longer.

If you’re looking for the highest quality print job, screen printing is a clear choice. With its superior color reproduction and durability, screen printing gives you the best bang for your buck. So if you want to make a lasting impression, choose screen printing!

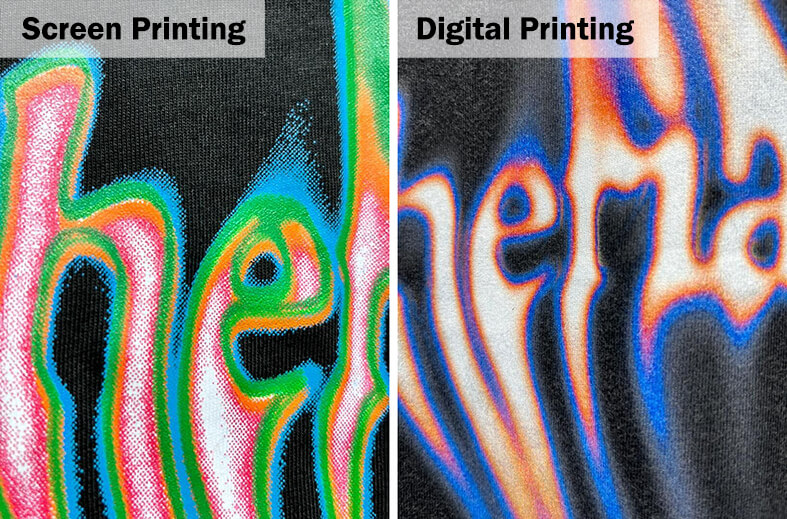

Screen Printing vs. Digital Printing: Color Blending

Screen Printing vs. Digital Printing: Color Blending

Color mixing is the ability to create smooth gradations and a range of colors by mixing small amounts of colors together.

There are three different ways to achieve color mixing in screen printing.

- The complexity of color patterns is achieved by using different colored screens

- Using multiple rolls or plates in the printing process

- Using special dyes and techniques

Color mixing can also be achieved in digital printing in several different ways.

- By using different formulations of the basic color CMYK

- By printing multiple passes on a single sheet, each of which uses a different recipe.

- Printing different areas on a single sheet of paper using different inkjet heads or multiple workflows in a laser printer.

Both screen printing and digital printing work well for color mixing, but digital printing has the advantage of

- The entire workflow is done in one machine, whereas the screening process normally requires multiple machines.

So overall, digital printing needs to be easy to integrate, easy to use, easy to monitor, and easy to debug.

Most of the inkjet heads on the market today are for full-page digital equipment; however, it is almost impossible to use these types of inkjet heads on screen printing equipment. Even though there have been attempts to integrate water-based inkjet heads into the screen gate, this approach does not seem to be well received by the market.

Screen Printing vs. Digital Printing: Color Matching

When it comes to color matching, screen printing is the clear winner. Pantone can replicate any color the customer needs, including colors outside the CMYK range, supersaturated colors, and specialty inks. This makes it the perfect choice for when exact color reproduction is essential.

In addition, screen printing provides a more consistent print quality, which is important for achieving accurate colors.

Digital printing, on the other hand, is better suited for smaller print runs and complex designs. It also offers a wider variety of finishes, such as gloss and matte. However, screen printing is the superior option when it comes to color matching.

Screen Printing vs. Digital Printing: Details

When it comes to details, digital printing trumps screen printing every time. The smallest design elements, such as thin lines, small text, and tiny details, can all be reproduced with fidelity using digital printing methods.

Not only does this mean that the final print will include all the nuances of your design, but it also ensures that every print is identical.

In contrast, screen printing often results in a loss of detail and inconsistency from print to print. This is because screens can only hold so much ink, and that artwork with many small elements requires a higher screen mesh count, which can distort details.

Because digital printing doesn’t rely on screens, you can be sure that your prints will always look exactly how you want them to.

Screen Printing vs. Digital Printing: Durability

Screen printing vs. digital printing: durability is the lasting quality of a print, and it’s something that digital printing has been striving to improve from the outset. In the early days of digital printing, you were lucky if you could get 10 washes out of a t-shirt before the colors started to fade. These days, a well-made digital print can withstand dozens of washings.

Digital printing has come a long way in terms of durability, but there are still some advantages that screen printing has in this area.

Screen prints are typically more resistant to fading and wear over time and can also be applied to a wider range of fabrics. So if you’re looking for a print that will last for years, screen printing may be the way to go.

Screen Printing vs. Digital Printing: Comfort and Feel

Few things to keep in mind for comfort and style.

Flexibility

Screen prints are usually accomplished on a thicker, less comfortable fabric. In contrast, digital prints provide the opportunity to be done on a flexible variety of fabrics that are much more pleasant to wear – especially for people with delicate skin.

Breathability

Screen printing often leads to discomfort because it involves laying down a thick layer of ink on the fabric. This can trap heat and moisture against the skin, which is especially unpleasant in hot weather. Digital prints are superior because they are much thinner and allow air to flow freely through the fabric.

Weight

Digital prints are typically lighter than screen prints. This is because screen printing involves layering ink on the fabric, which can add significant weight to the garment. Digital prints are much thinner and lighter, making them more comfortable to wear for extended periods.

Texture

Unlike digital prints, screen printing generally results in a rough texture because of how the ink is applied to the fabric. The smoother finish from digital printing makes it more comfortable to wear against your skin.

Screen Printing vs. Digital Printing: Consistency

Screen printing vs. digital printing: consistency is key to print quality. With digital printing, there is less need to worry about variables because the machine processes the file and prints it directly onto the shirt. This results in a more consistent print quality overall.

With screen printing, on the other hand, each print run can be slightly different depending on the mesh count of the screen, the thickness of the ink, and other factors. This can lead to inconsistencies in print quality from one batch to the next. For businesses that require a consistently high level of print quality, digital printing is the way to go.

Screen Printing vs Digital Printing: Special FX Inks

If you want your prints to really stand out, special effects printing is for you. Special effects inks and additives can add extra dimension, texture, luminescence, and glow to make an eye-catching piece.

Here are some examples of specialty inks and additives:

- Emission: Chemicals work to remove the color from fabric dyes.

- Powder Puff: As this additive cures, it expands and gives a soft, raised feel.

- Fluorescent: Excessively bright neon colors that are visible even in daylight.

- Metallic: A type of ink that gives off a shiny reflective surface, often in colors such as gold, silver, or copper.

- Glitter: The glitter in this product creates a shining effect, typically used in tandem with a clear gel.

- Glow-in-the-dark: This ink is activated by light and will glow almost transparently in the dark.

- Shimmer: Gives your project a one-of-a-kind, shimmering look.

Click to know more about each different ink.

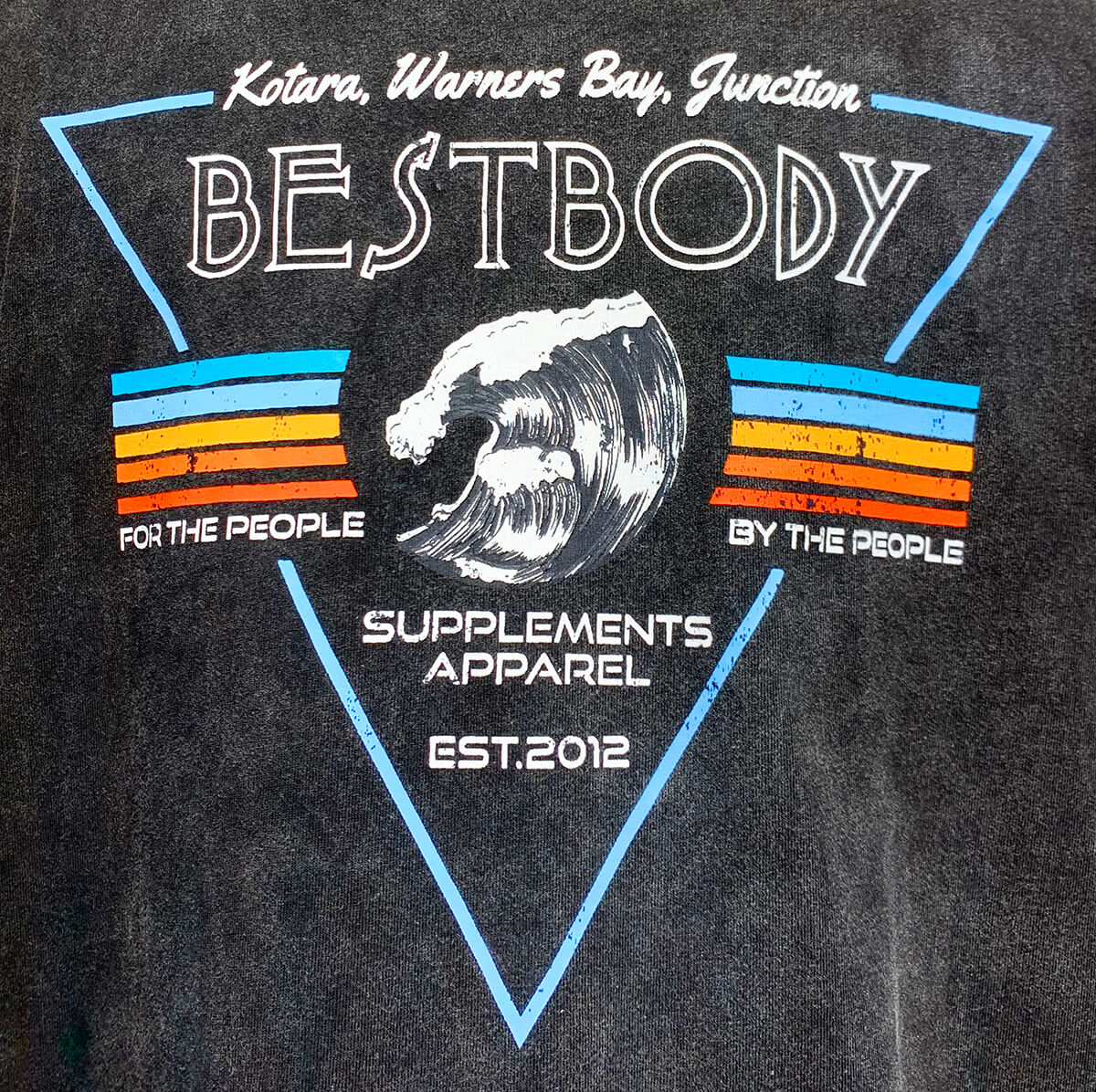

Screen Printing vs. Digital Printing: Popularity

Screen printing is the most popular printing method among people and has been for decades. The main reasons why this classic printing method is so good at what it does are the same factors people look for when customizing their T-shirts: ink intensity, durability, and affordability.

Some of the advantages of screen printing over digital printing include the following:

- Screen printing produces vibrancy in colors that cannot be matched by digital printing, no matter how high the printer’s quality.

- The ink in screen printing permeates the shirt’s fabric, making it more durable and less likely to fade than digitally printed shirts.

- Screen printing is a more affordable option for those looking to print in large quantities.

There are some disadvantages of screen printing as well, such as:

- The setup process for screen printing is more time-consuming than digital printing, which can be done by pushing a button.

- Screen printed shirts often have a “hand feel” that some people do not like as it can be stiffer than a shirt that is made with digital printing.

- Screen printing can be limited in terms of the number of colors that can be used, while digital printing has no such limitations.

However, despite these disadvantages, screen printing remains the most popular choice for those who are looking to customize their own shirts.

Wrapping up

Clearly, both digital printing and screen printing have advantages and disadvantages. Your best option depends on your specific needs.

If you need a large quantity of shirts printed quickly and affordably, screen printing is the way to go. If you need a smaller quantity of shirts with consistent print quality and a wide range of color options, digital printing is the better option. And if you want your shirts to really stand out with special effects inks, both printing methods can get the job done.

What’s most important is that you find a printing method that meets your needs and budget. Whichever printing method you choose, make sure to work with a reputable company that has experience in the industry. This way, you can be sure that your shirts will turn out looking just the way you want them to.