Have you heard about DTG (Direct-To-Garment) printing? Over the last two decades, DTG (Direct-To-Garment) printing method – also known as digital printing – has come a long way! It used to be a newcomer to the custom garment market, but now it’s giving traditional screen printing a run for its money regarding quality and cost.

When it comes to designing clothes, we use both of these methods all the time and can vouch for their reliability. However, like anything else, each method has its own unique set of advantages and disadvantages.

What is Screen Printing?

Screen printing is one of the oldest and most popular methods for decorating apparel! This technique, called silkscreen, has been around for thousands of years. Here’s how it works: ink is applied to the fabric through a series of stencils (screens) that are layered on top of each other. Then the ink is cured (heated) to make it solidify.

Because screen printing uses thick inks, the design sits on top of the fabric rather than soaking in. Before DTG printing came along, screen printing was the only way to print designs on t-shirts. Even though DTG printing has become more popular, screen printing is still a great option – especially for those looking for the best quality print.

What Is DTG Printing?

DTG printing uses a pretty cool technique called the “process” method to create a whole bunch of colors using just four or six base colors. Those colors are cyan, magenta, yellow, black, red, and green. DTG machines are giant inkjet printers, similar to the one you might have in your home office, but way more powerful and designed specifically for printing on t-shirts and other apparel.

Difference between DTG and Screen Printing

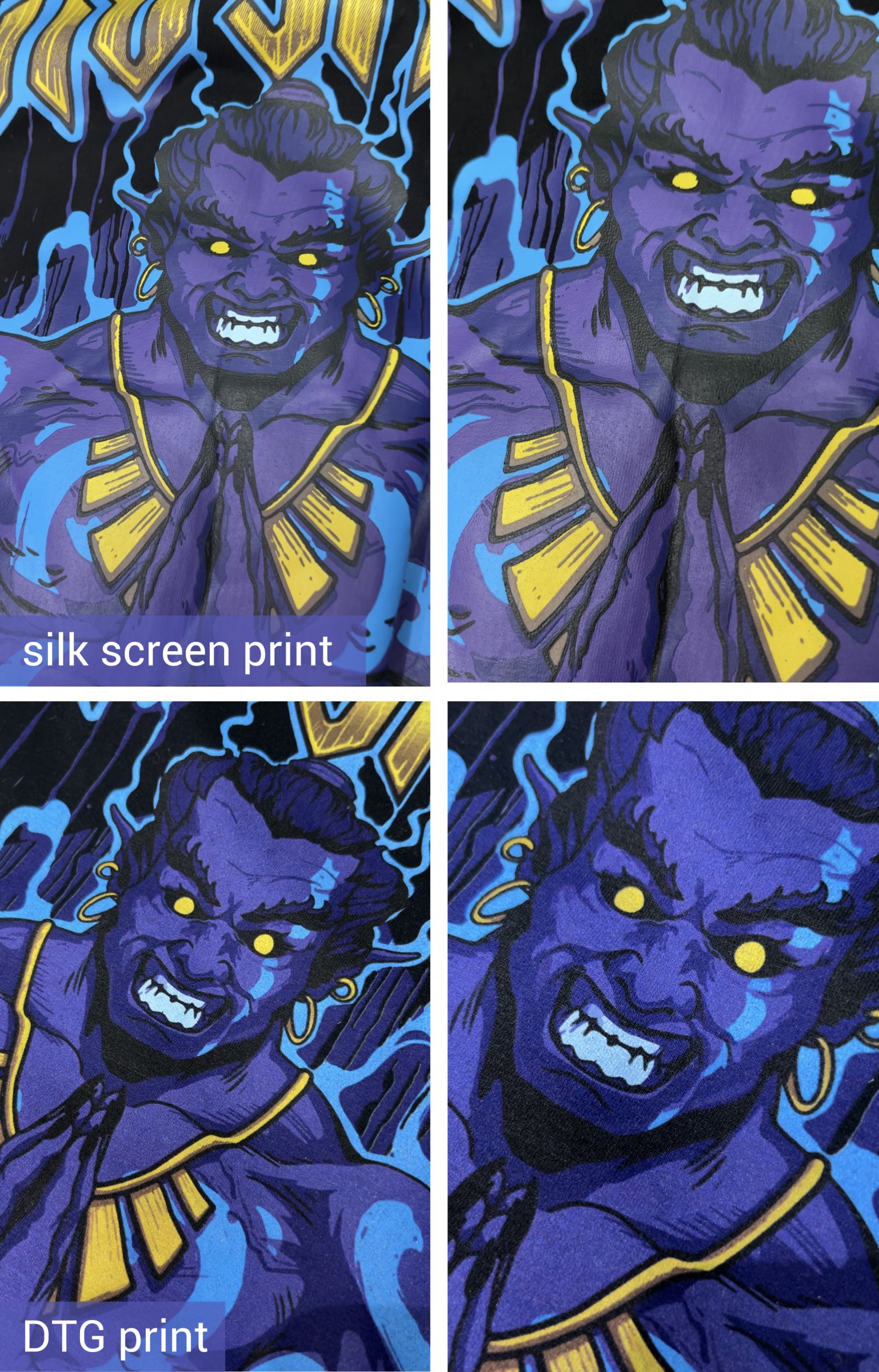

Direct-to-Garment (DTG) printing and screen printing are often compared to each other, yet both methods have their own unique set of pros and cons! When it comes to DTG printing, the process involves printing colors using tiny CMYK-style dots instead of solid blocks of ink like in screen printing. While this method doesn’t produce the same intensity of color as screen printing, it can still create some pretty amazing designs. One thing to note, though, is that a digital printer can’t replicate the textured effects that screen printing can produce.

On the other hand, DTG printing doesn’t require a stencil to create a design. This means that the end result can be incredibly detailed, almost like a photograph! DTG printing is a more cost-effective choice for smaller quantities of garments or even just one item. And if you’re looking to create a photographic or intricate design, DTG printing is the way to go!

Vibrancy

If you are ready to make your design stand out from the crowd, then screen printing might just be your method of choice! Screen printing is all about delivering a powerful punch of color saturation and brightness.

While DTG printing has come a long way, it still can’t quite match the vibrancy of screen printing. This is because digital printing uses water-based inks, which can lack the opacity and brilliance of plastisol – especially on darker-colored clothes. That being said, DTG machines have come a long way and can now produce bright under bases using a plastic particle pre-treatment and titanium dioxide white ink. However, the final result may still not quite match the intensity of screen printing.

Color blending

There is no doubt that DTG has an absolute chance of winning regarding to color blending. The outstanding color blending capabilities of DTG printing is amazing! But what exactly is color blending? It’s the ability to mix fewer colors and create a wide range of hues and smooth gradients. DTG printers were specifically designed to excel at just that!

While it is possible to use a process called “simulated process” to turn spot colors into a spectrum, the setup required can reduce efficiency – especially for smaller orders. Plus, the outcomes can vary, which can be frustrating for those seeking precise results. Depending on your graphic design, DTG will come out around 90-95% similar to your document.

When it comes to gradients or precise blends, such as those required for skin tones, DTG printing is more dependable than screen printing. Plus, with little to no setup required, you can get started on your order right away!

Color Matching

Screen printing’s ability to precisely match colors is making a comeback. Thanks to process inks and inkjet printing, Pantone matching is possible with screen printing. While DTG printing claims to match Pantone colors, it is only within the CMYK range.

Even with the introduction of bright green and red slots on advanced DTG machines, it still falls short of screen printing’s ability to create a color palette that covers every shade imaginable.

Although there are a few colors that cannot be printed with screen printing, its overall range is much broader than DTG’s. When it comes to exact color matching, screen printing is the clear winner. Choose screen printing when you absolutely must have your brand’s colors spot-on!

Details

Have you ever noticed tiny dots in a screen-printed design? That’s because screen printing uses halftone dots to create shades of color and gradients. But with DTG printing, the dots are so small that you can’t even see them!

In screen printing, the halftones are generated from a program called a raster image processor (RIP) at a certain number of lines per inch (LPI). DTG also uses halftones, but with a maximum print resolution of 1,200 DPI and a technique called diffusion dither. This means that the halftones are created using frequency modulation instead of amplitude modulation. Therefore, in terms of details, DTG does a better job.

What Is More Durable DTG Or Screen Print?

When it comes to washability, screen printing has a slight edge over DTG. But that doesn’t mean DTG prints aren’t durable! If a DTG print starts to fade or peel after washing, it might be due to improper preparation or curing. The quality of the inks and machine also plays a role in how long the print lasts.

To ensure your DTG prints last, it’s essential to follow proper washing and care instructions. Avoid using hot water, harsh detergents, and excessive heat in the dryer. If you take care of your DTG prints, they should hold up beautifully over many washes.

Feel

With screen printing, it’s possible to create a distressed look by reducing the ink’s surface area, making it more flexible and resulting in a softer hand. However, this technique isn’t suitable for every order, as it depends on the customer’s preference and the design itself.

Typically, screen printing involves a standard layer of ink, with an additional layer on dark fabrics that requires an under-base. While this method creates durable prints, the ink can feel heavy on the shirt.

In contrast, DTG printing produces a super soft and breathable feel without any plastic sensation, making it a great option for those seeking a more comfortable garment.

Popularity

As DTG technology continues to evolve and become more widespread, the distinction between DTG printing and screen printing may no longer be as important. While screen printing has been a fan favorite for a long time, as DTG technology improves, it may become harder for most people to differentiate between the two printing methods.

It’s hard to say which printing method is more popular, it depends more on your design and your request for the printing effect.

How Long Do DTG Prints Last?

Direct-to-garment printing (DTG) is a top-notch way to create long-lasting prints on clothing. You may have heard rumors that DTG prints only hold up for about 50 washes, or that 50 washes are the industry norm for printed apparel.

But don’t believe the hype – the durability of a print depends on several factors, such as how often you wear and wash the garment, the water temperature, the type of detergent used and more. No set number of washes will cause a DTG print to fade or wear out. In fact, the lifespan of a DTG print is typically equal to that of the garment itself!

With DTG, you can achieve a retail-quality finish that’s just as durable as clothing you’d find in major retail stores. In fact, many retailers use DTG printing for their products.

This method ensures that all your custom t-shirt designs will be of the highest quality and built to last. So don’t worry about your prints fading after a few washes – with DTG, you can enjoy your custom apparel for as long as you would any other item in your wardrobe!

How Long Do Silk Screen Prints Last?

Silkscreen prints can last for a very long time if they are properly cared for (wash according to the instructions on the care label). How long it last depends on various factors, such as the quality of the materials used, the conditions under which the print is displayed and stored, and the level of care taken in handling and maintaining the print.

In general, silkscreen prints made with high-quality materials can last for at least washing 50 times, or even more, without significant fading or deterioration. However, prints that are displayed in direct sunlight or in humid environments for a very long time will experience more rapid fading or deterioration.

Some last words

Ready to start printing your personalized clothing? By learning more about the differences between screen printing and DTG printing in terms of durability, cost-effectiveness, quality, and quantity, you can make an informed decision on which technique is best for your company’s needs.

And if you still have questions, don’t hesitate to contact us! Here at Lezhou Garment, we are always here to help you achieve the perfect finished product that will effectively represent your client’s brand.