As the fashion industry has become increasingly globalized, the importance of having clear and concise sample order terms has never been greater. When working with suppliers from around the world, it is essential to have a document that outlines all of the terms and conditions of the sample order.

This will help to ensure that both parties are clear on what is expected and that there is no misunderstanding. Additionally, having well-drafted sample order terms can help protect your company’s intellectual property rights if there are any issues with the samples.

What is pre-production sampling?

Pre-production sampling, or pre-pro samples, are product samples that occur before mass production begins. Pre-pro samples can help buyers check on designs, including sewing, labels, or any other manufacturing process that needs to be confirmed before large-scale production starts.

By doing a pre-production run, factories can catch any errors or potential problems with the design before full production begins. This can save a lot of time and money in the long run. Pre-production sampling is an essential part of the manufacturing process for many companies, and it helps to ensure that products are of the highest quality before they hit store shelves.

Why are pre-production samples so important?

Pre-production samples are so important because they help ensure that the final product is of the same quality and standards as the original product conceived during the product development process.

It allows companies that require PP samples to assess a garment factory’s ability to meet the pre-agreed quality requirements of the product. The only way to test if a design is possible and a manufacturer can handle production is by having them create pre-production samples.

How to draft pre-production sample order terms

Developing pre-production samples can be simple. In fact, the first step is simply drafting PP sample order terms. By having a well-drafted document, you can avoid sample development costs and delays caused by revisions.

Keep reading to learn how to draft your own counter sample order terms document that includes product specifications, compliance requirements, provisions for revision requests, and tool ownership clauses.

Product Spec Sheet & Attachments

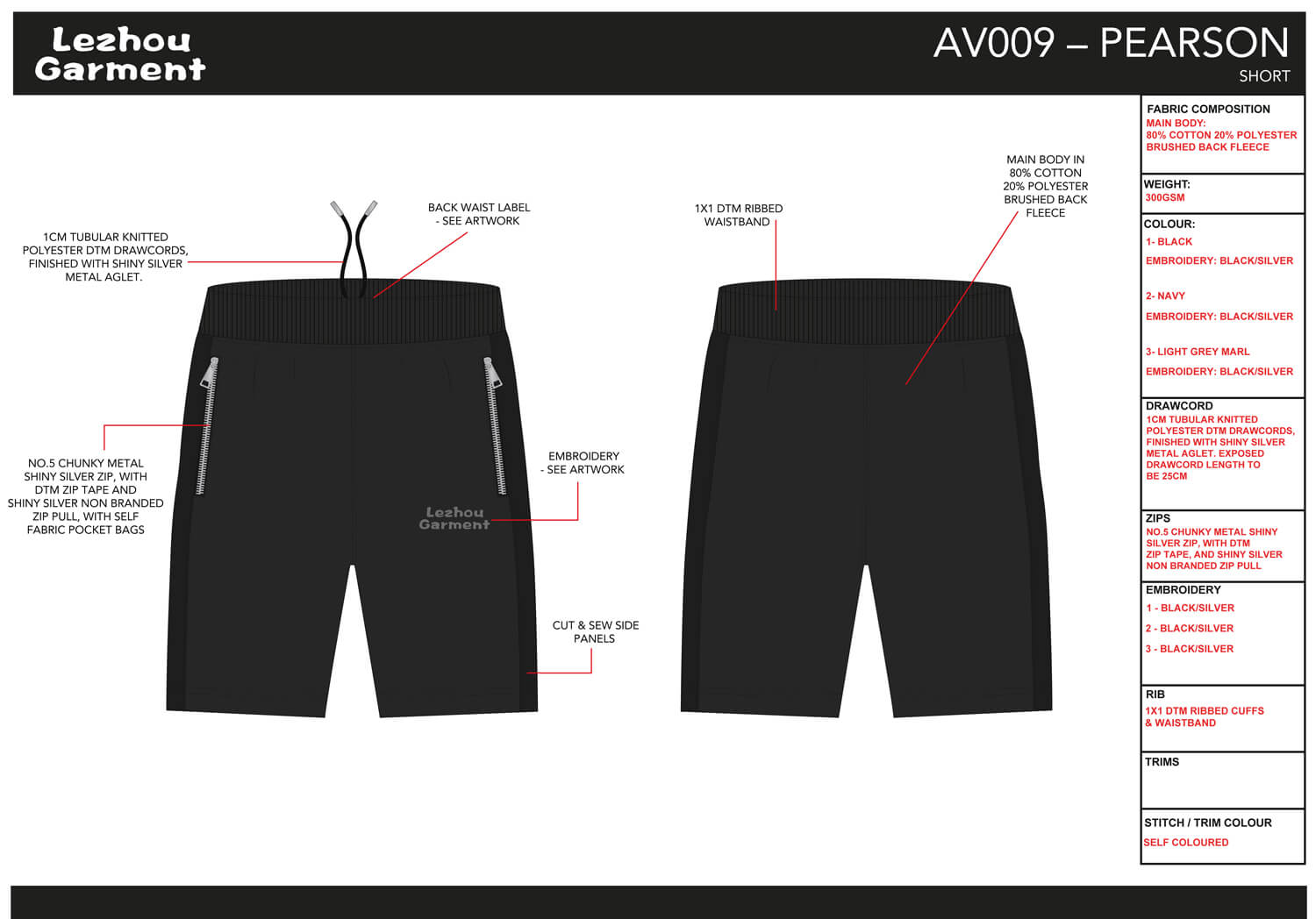

Product specification sheets and attachments are essential for custom clothing production. They provide manufacturers with vital information about the product, including design, materials, sizing, and color. With this information, producing a high-quality, consistent product is easier.

There are a few things to keep in mind when creating a product spec sheet or attachment for custom clothing production:

- Include all relevant information: Manufacturers will need CAD files, design drawings (ANSI or ISO standard), a material list, a size set chart, and color codes (Pantone or RAL).

- Include reference samples: It can be helpful to include reference samples of similar products and fabric and trim swatches.

- Be clear and concise: Make sure the information is presented clearly and easily understandable.

Following these guidelines ensures that your custom clothing order will be produced correctly and to your specifications.

Product safety standards and material restrictions

Product safety standards and material restrictions must be communicated to manufacturers before processing samples. Even though you will still need to communicate all applicable standards and regulations to your suppliers, do not assume that they will be able to assemble “compliant samples” for the above reasons.

- Lack of understanding of the requirements: Some manufacturers may need to clearly understand the product safety requirements and material restrictions that apply to your products. As a result, they may inadvertently use materials or processes that do not meet your standards.

- Inability to meet all requirements: In some cases, manufacturers may meet most, but not all, product safety requirements and material restrictions. For example, they may be able to source the correct materials, but their manufacturing process may need to improve.

- Refusal to comply: In some cases, manufacturers may be aware of the product safety requirements and material restrictions but refrain from complying with them. This could be for various reasons, such as believing compliance is too expensive or time-consuming.

Regardless, it is important to know that not all manufacturers can meet your product safety standards and material restrictions. As a result, consider alternate suppliers or make arrangements for additional testing before moving forward with bulk production.

Product Packaging & Labelling Requirements

Developing new product packaging can be a challenge in itself. But whether you’re buying off-the-shelf (ODM) or custom-designed (OEM) packaging, you’ll need to include the following:

- Your company name and logo

- The product name and/or brief description

- The size or dimensions of the product

- Any warnings or cautions that are required by law

- The country of origin (if required by law)

- The contact information for your company

If you’re selling a physical product, then you’ll likely need to include extra information like:

- Nutrition facts

- Ingredient list

- Directions for use

- Expiration date

If you’re selling products that will be shipped internationally, you’ll need to ensure that your packaging conforms to all relevant regulations. This can be a complex process, so working with a knowledgeable packaging supplier who can help you navigate the requirements is important. By ensuring that your packaging meets all legal requirements, you can help avoid problems down the road.

Production time and revisions included.

To avoid being caught off-guard financially, agree on the following terms with your supplier before purchasing any prototypes:

- Production time: Include the days or weeks the supplier estimates it will take to produce the prototype.

- Revisions: Indicate how many revisions are included in the price. If additional revisions are needed, specify whether the supplier can charge extra or if you will absorb the cost.

- Quality control: Make sure your supplier agrees to check each prototype for accuracy before shipping it to you. That way, you can be confident that what you receive meets your specifications.

With these terms in place, you can avoid misunderstandings and unexpected costs.

Mold and Tooling Ownership

When buying products with custom designs, it is often necessary to purchase injection molds and other tools. Molds are always paid for by the buyer and can represent a large portion of the product development cost. As a result, the buyer needs to avoid any of the following situations:

- Paying for a mold that is not used

- Paying for a mold that does not meet specifications

- Paying for a mold that is not compatible with the bulk production process

To avoid these situations, it is important to add the following clauses to sample order terms from buyers:

- The buyer will only pay for molds that are used.

- The buyer will only pay for molds that meet specifications.

- The buyer will only pay for molds compatible with the production process.

By adding these clauses, buyers can protect themselves from paying for molds that are not usable, meeting specifications, or compatible with production.

Subcontracting

The purpose of purchasing pre-production samples from a manufacturer is often to test their ability to produce your design. However, what if the manufacturer subcontracts the production of the sample to another factory? In that case, you would likely want your pre-production sample in the right hands.

To avoid this, add the following clause to your agreement with the manufacturer:

- The [Manufacturer] shall not subcontract the production of any pre-production samples without the prior written approval of the [Buyer].

- If the manufacturer does subcontract production, they shall be solely responsible for ensuring that the quality of the finished product meets the [Buyer]’s specifications.

This clause will help protect you from surprises and ensure you get the quality product you expect.

Terms of Payment

When ordering products that require expensive tooling or molds, it is common to pay a 100% deposit upfront. This is because there is a higher risk associated with these orders. To mitigate this risk, we recommend using the following terms of payment:

- A 40% deposit upfront before the production of tools and pre-production samples begins.

- The remaining 60% balance will be paid after the buyer has approved the mold(s) and pre-production sample(s).

If properly managed, these terms can help protect both the buyer and seller in case of any unforeseen issues.

NDA (Non-Disclosure Agreement) Attachment

As anyone who has ever developed a new product knows, keeping your design, functionality, or brand a secret can be difficult. You want to prevent your suppliers from selling your product or brand to other buyers, but you also need them to sign a Non-Disclosure Agreement (NDA) to protect your intellectual property. So what should you do?

In theory, an NDA can prevent a supplier from doing any of the following:

- Selling your product to another buyer

- Copying your product design

- Reverse engineering your product

- Sharing your trade secrets with competitors

However, NDAs are only sometimes 100% effective. If your product is unique and faces a serious risk of being copied, you may want to take the following steps:

- Work with a lawyer to create a legally binding NDA

- Make sure that the NDA clearly defines what information is considered confidential

- Include strict penalties for breaching the NDA

- Choose a supplier that you trust

- Keep communication open with your supplier

These precautions will help protect your intellectual property.

Wrapping up

Creating a well-crafted agreement with your supplier is crucial to maintaining a harmonious business relationship while avoiding potential difficulties. Make certain that your expectations are articulated accurately and succinctly to preclude any possible misinterpretation. With the help of the guidelines set forth in this article, you can aid in making sure that your next pre-production sample order is straightforward.