If you’ve been dreaming about launching your very own clothing brand, maybe you’ve already come up with some ideas and thought about tapping into the growing demand for trendy products in the market. But let’s face it, starting a business can be overwhelming, and you might still have a few unanswered questions.

You might be wondering, how you can find the perfect manufacturer for your product idea. Now, the age-old question – is it better to work with manufacturers near you or abroad? How to make sure that the manufacturer you wish to work with is legitimate?

In this post, I’m going to dive into the nitty-gritty of supplier sourcing. I’ll discuss some options for places to search. I’ll also share tips on how to approach potential suppliers when you’ve found them and what to ask them about their process when developing a collection to determine how they can help you with the first collection of your brand.

Domestic vs. overseas suppliers

When it comes to manufacturing and wholesale suppliers, you have two options: sourcing domestically or overseas. And let’s face it, overseas can refer to anywhere on the globe.

You may be asking yourself, “are companies near me better to work with than companies overseas?” The answer to that question is a little compounded.

When it comes to manufacturing and wholesale, it’s always a good idea to have a backup plan. In this case, it is best to have a domestic and overseas supplier. By having two manufacturers in your hand, you’re covering all your bases. If your overseas supplier is late or incorrect, your local manufacturer comes in as the trusty backup. They may be a bit pricier, but it’s better to have products stocked and customers happy than having them wait for overseas shipments to arrive.

When it comes to sourcing your products, overseas can sometimes be the best way to go as it is often cheaper. Countries like China, India, and Taiwan can offer some pretty low labor costs. However, apart from just the upfront investment and cost per unit, there’s a whole lot more to consider.

Both domestic and overseas sourcing have their advantages and disadvantages:

Domestic sourcing

Advantages

• Strict manufacturing and labor standards to ensure high quality

• Seamless communication without any language barriers

• Marketing advantages of being locally made

• Simplified verification of trustworthy manufacturers

• Quicker delivery times

• Robust protection of intellectual property rights

• Enhanced payment security and legal remedies

Disadvantages

• Increased manufacturing expenses

• Limited product variety (some products may not be available locally)

Overseas sourcing

Advantages

• Reduced manufacturing expenses

• Abundance of manufacturers to select from

• All-in-one platforms like Alibaba have simplified supplier discovery and engagement

Disadvantages

• Generally lower manufacturing and labor standards

• Insufficient protection of intellectual property rights

• Challenges in dealing with language, communication, and time-zone differences

• Expensive and complicated to confirm manufacturer identity and conduct on-site visits

• Extended delivery periods

• Divergent business customs due to cultural differences

• Product import regulations and customs clearance

• Limited payment security and legal remedies.

How to find a clothing manufacturer?

Finding a reliable manufacturer can make or break your business! The price, quality, packaging, and shipping of your product are all in their hands. Here are 4 killer tips for finding the perfect clothing supplier.

Alibaba

Alibaba is your answer to finding top-notch manufacturers in China. It is a marketplace that offers a sea of existing products, but it also lets you connect with manufacturers to create custom goods. Simply search for the product you want and there will be a plethora of suppliers available to you.

Safely buying on Alibaba is easy. Alibaba’s amazing vetting system can vet manufacturers upfront to bring you the best products at the best price. Here are the qualities you must look for when researching manufacturers on Alibaba:

• Gold suppliers – these suppliers pay for an Alibaba membership!

• Verified – this means a third-party evaluation company or Alibaba has personally visiting their manufacturing site.

• Trade assurance – a service that shields your orders from payment to delivery. This service is free!

If you cannot immediately find what you want, Alibaba allows you to apply filters. Look for manufacturers with certifications that are in alignment with your brand’s value (like the SA8000 certification which is all about humane working conditions).

One more thing to keep in mind when using Alibaba to source your products: always steer clear of trading companies. Trading companies are just middlemen and don’t won’t be able to produce your products.

Directories

Another place to research manufacturers is free online supplier directories. These directories act as manufacturer catalogs that contain profiles for hundreds or thousands of manufacturers, wholesalers, and suppliers. Below, we’ve listed a few of the most popular ones for both domestic and overseas suppliers:

Other great spots to find manufacturers are in free online supplier directories! These are like manufacturer catalogs with hundreds or even thousands of profiles of manufacturers, wholesalers, and suppliers. Here are some of the best directories for both domestic and overseas suppliers:

Online domestic directories

Online overseas directories

- AliExpress (See our ultimate guide on AliExpress)

- Indiamart

- Sourcify

With the internet, we can easily search Google and find what we’re looking for in only a couple of minutes. But when it comes to finding suppliers, things aren’t always so simple as many suppliers just haven’t kept up with the times, which means their websites might be old, with little to no useful information and poor search engine optimization.

So how do you use Google to find the right supplier for you? You’ll need to thoroughly search page 2 and beyond in your Google search results. Use keywords like clothing factory, garment wholesale, or clothing manufacturer in the search engine, as these words may be used interchangeably, so search them all.

Familiarizing yourself with Google’s search shortcuts can help you tremendously with your search and thus you can get better results as well.

Referrals

Referrals can be a great source of high-quality leads. Don’t hesitate to reach out to your professional network connections and ask for their recommendations. Seek out people who have achieved success in your desired field and ask if they’re open to sharing their contacts.

Thanks to social media, it’s easier than ever to spread the word. Consider joining Facebook groups, Linkin and other online communities of e-commerce business owners, and look for glowing reviews.

When you start selecting suppliers, even if you don’t end up working with a particular supplier, it’s always a good idea to ask if they can point you in the right direction. As insiders in the industry, they likely have many contacts and would be happy to recommend a better fit for your needs.

Outreach and collection of information

After identifying several potential manufacturers, it’s time to request quotes. It’s a good rule of thumb to gather at least three quotes to compare options effectively.

Naturally, one of the most pressing questions on your mind will be the cost. However, before you request quotes, it’s crucial to have answers to the following questions:

- Can they handle custom orders? Examine whether the supplier or manufacturer has the necessary skills and resources to create the product you want. Do they have automation features to streamline production?

- What are their leads times? It’s crucial to know how long it will take to produce and ship items. Avoid working with manufacturers who take too long to deliver your products, as it could lead to long wait times for your customers.

- What are shipping costs? Shipping expenses can add up quickly and significantly impact your bottom line. Learn about a manufacturer’s shipping costs to determine how it will affect your profit margins.

- What are their minimum order quantities (MOQs)? While this question can make you look like a beginner, it’s essential to know the minimum number of items you need to order before the manufacturer will start production. This is highly negotiable.

- What is the cost per unit? Negotiate the cost per unit while also negotiating MOQs. Typically, the larger the order, the lower the cost per unit will be.

- What’s their defect policy? Find out who covers the cost for incorrect or defective items. Who is responsible for paying for shipping and duties?

- Is the manufacturer sustainable and ethical? Check the factory conditions to determine their impact on the environment and workers. It’s important to work with manufacturers who operate in a sustainable and ethical manner.

Negotiating minimum order quantities

If you’re searching for a supplier for the first time, you’ll quickly become familiar with the term “minimum order quantities” (MOQs). Depending on the product and manufacturer, some manufacturers may require a commitment to purchase hundreds or even thousands of units for your first order.

However, MOQs can pose a challenge when you’re just starting out, want to start small, or have limited funds and test the market before making larger purchases. The good news is that MOQs are almost always negotiable.

Before negotiating, take the time to understand why the supplier has imposed a minimum order quantity. Is it because there’s a lot of work involved upfront, or is it because they prefer to work with larger buyers? Understanding the reasons behind the minimum will enable you to propose the best counteroffer and negotiate effectively.

Discussing payment terms

It’s common for suppliers to require new businesses to pay for the full order upfront. This is crucial to know, as inventory is a significant expense for e-commerce businesses. It’s worth asking if they provide payment terms for future orders.

Suppliers receive numerous email quote requests from potential buyers who may not be serious, and as a result, many suppliers may not reply to every inquiry. A lack of supplier responsiveness is a typical complaint of new ecommerce entrepreneurs.

So, how can you guarantee that you don’t get ignored? There are some things to avoid when reaching out to suppliers for the first time:

- Long emails: Your first email to a manufacturer should purely assess potential fit at a high level. Avoid sharing too much about yourself and your background. Focus on what suppliers’ care about the most, like the details of what you’re trying to source.

- Asking for too much: While it’s important to ask about pricing for multiple quantities, don’t ask for large quantities or too many quotes. Only ask what you absolutely need to know to assess the fit between you and the supplier.

- Asking for too little: If you ask for a quote well below the supplier’s minimum order, you risk being met with silence. If you’re unsure whether your request is too small, consider calling them or sending a one-question email prior to asking what their minimum order is.

It’s possible to negotiate payment terms with a reliable manufacturing supplier. A reliable supplier won’t pressure you to pay 100% upfront before receiving your shipment (if they do, that could be a red flag). Instead, consider proposing a deal where you pay 50% upfront and 50% after receiving the shipment. This ensures that both parties are accountable for the order and minimizes the risk involved for either side.

Communicating with manufacturers and suppliers

You probably won’t have a manufacturing manager to handle supplier communications when you’re starting your business, you’ll have to do this on your own. Here are three effective ways to do it:

- Skype calls/ Whatsapp calls

Seek out companies that respond promptly and show a willingness to collaborate. If a company is slow in responding to your emails and samples, they might not be the correct partner for you.

Communicate your designs

When you talk with a potential manufacturer, inquire if they can create your design. Some manufacturers offer a product development process with prototyping and 3D modeling, but it can be expensive.

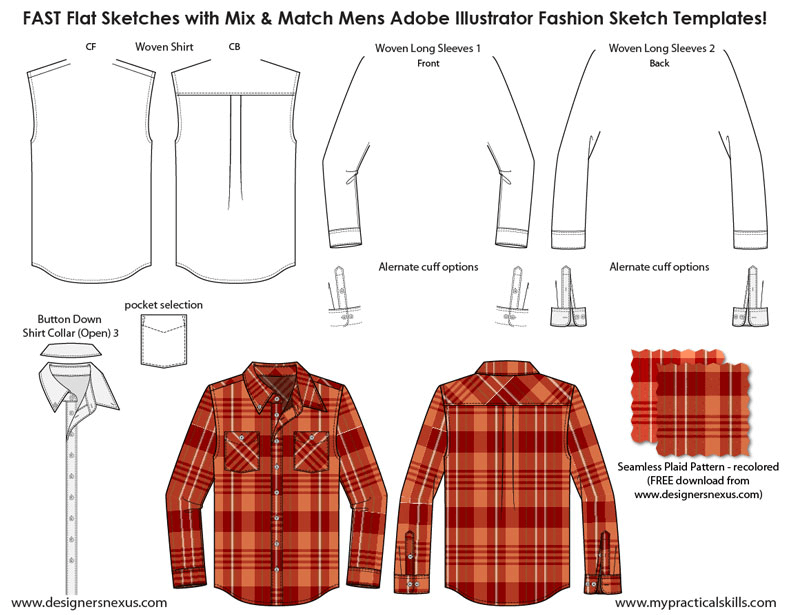

As an alternative, communicate your ideas with them through:

- Sketches

- Instructions

- Reference photos

If the company does not offer design services, you can use Fiverr or Upwork to find freelancers who can create drawings for you. Consider hiring:

- Indstrustial designers

- Product designers

- CAD experts

You can also find a local designer as another option. You can collaborate with them to develop prototypes and custom molds, which is more affordable than going through a manufacturer.

Order samples

Get samples to test before going into production, before placing a full order. Once you have the sample, confirm that it is correct and then date and sign it. Save one or two for yourself. These are known as control samples, which are any type of sample used to assure quality and get consistent consumer products.

For instance, if a manufacturer sends you an order and the colors are completely wrong, you would likely discuss the issue with your manufacturing partner to resolve the mistake. If there are any doubts about the order, you can refer to the control sample to show that the products you received are not what was previously agreed upon.

Negotiate

While you have the sample and before placing your order, it is still possible to negotiate terms such as payment or MOQ. When negotiating, try to understand the manufacturer’s perspective. The goal is not to exploit your manufacturing partner for the best price, but to work together so that both parties can profit and be satisfied. This is the best way to cultivate a long-term relationship.

Place your order

Finally, place your order and perform a 100% quality control check before proceeding. Verify that every product they have sent you meets your standards. If you are satisfied with everything, send your order and initiate the production process!

Finding your supply partners

The process of sourcing suppliers and manufacturers is quite unique, but it is one of the costs of starting a business. Finding suppliers that are a good fit is a crucial decision for your new business, and it is not always an easy task.

It is common to feel frustrated when encountering dead ends or obstacles, but in most cases, finding the perfect partner for your new venture simply requires a little more patience and perseverance.

For the past 19 years, we have been dedicated to providing one-stop clothing manufacturing services for small and medium-sized clothing brands. Send us your design today, and our team will offer you the best solution for achieving success with your designs.