Printing on clothing is a popular way to add personal style, branding, or marketing messages to garments. There are several different techniques used to print designs onto clothing, each with its own set of benefits and limitations. Here are some of the most common types of printing methods used in the clothing industry.

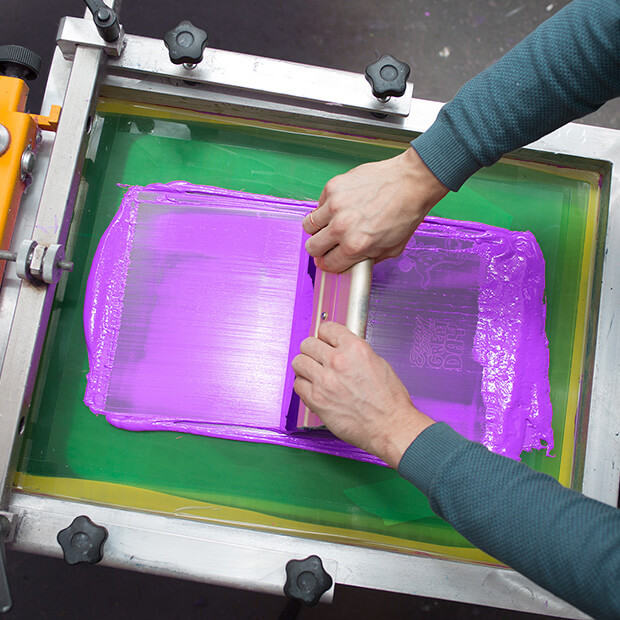

Screen printing

This is a widely used method that involves creating a stencil of the design (known as a screen), and then using a squeegee to apply ink through the screen onto the garment. Screen printing is a cost-effective way to produce large quantities of garments with a single color or simple design. However, it can be time-consuming and labor-intensive for more complex designs or multiple colors.

Here are some advantages and disadvantages of silk screen printing:

Advantages

- Durability: Silk screen printing is known for producing long-lasting, high-quality prints. The ink is applied thickly, which makes it resistant to fading and wear.

- Versatility: Silk screen printing can be used on a wide range of materials, including fabric, paper, wood, and metal.

- Cost-effective: Silk screen printing is a cost-effective option for producing large quantities of prints. The setup costs are relatively low, and the prints can be produced quickly and efficiently.

- Precision: Silk screen printing allows for precise registration, which means that the colors will be aligned correctly and the print will be consistent.

Disadvantages

- Setup time: Setting up a silk screen printing job can be time-consuming, as the screens need to be created and the ink needs to be mixed.

- Limited colors: Silk screen printing is limited to a single color per screen, so printing multi-colored designs can be more complex and time-consuming.

- Ink buildup: If the ink is not applied correctly, it can build up on the screen and create a blurry or uneven print.

- Limited print area: The size of the screen limits the size of the printable area, so larger prints may require multiple screens or additional setup time.

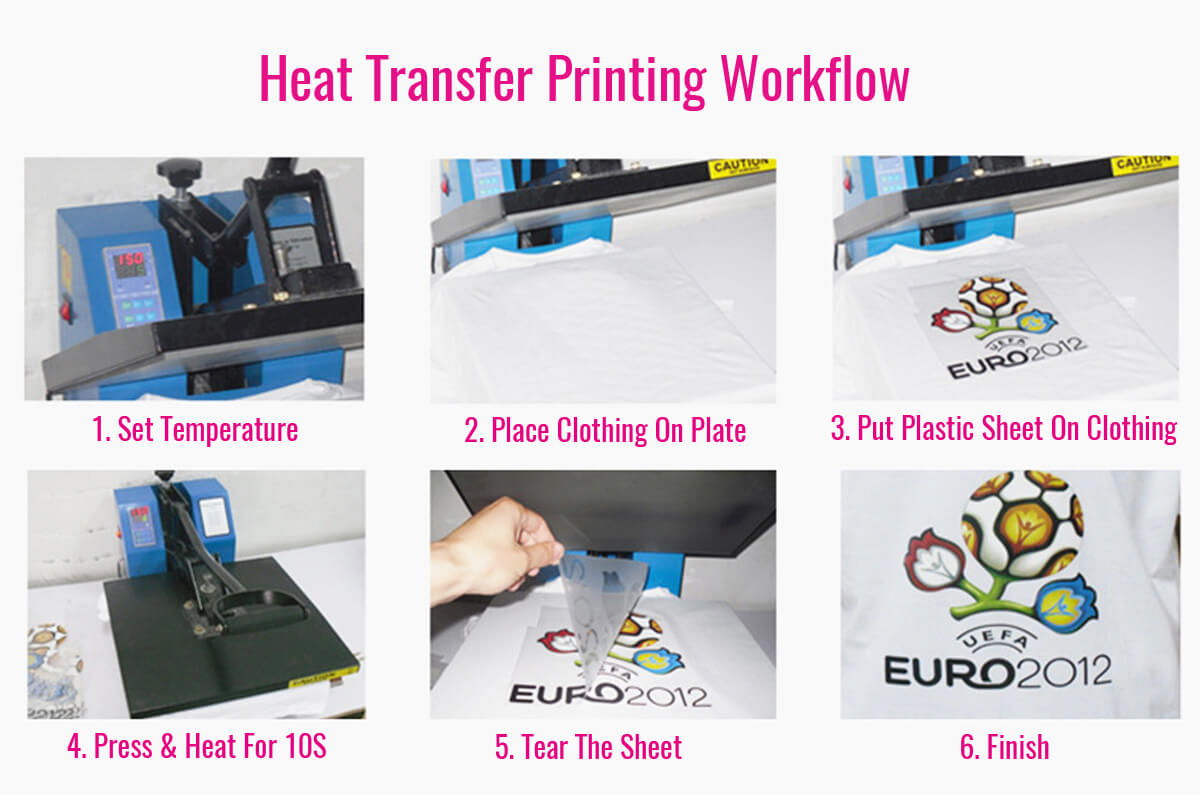

Heat transfer printing

Heat transfer printing involves printing a design onto a special transfer paper, and then using heat to transfer the design onto the garment. This method is quick and easy, and it can produce high-quality prints with fine details. However, the prints may fade or peel over time, and the process can be damaging to some fabrics.

There are several advantages and disadvantages to this process:

Advantages

- Wide range of materials: Heat transfer printing can be used on a variety of materials, including cotton, polyester, and nylon.

- High-quality prints: Heat transfer printing produces high-quality prints that are sharp, vibrant, and durable.

- Fast turnaround: Heat transfer printing is a relatively fast process, making it ideal for large production runs or tight deadlines.

- Versatility: Heat transfer printing allows for a wide range of design options, including the use of full-color images, gradients, and text.

Disadvantages

- Limited fabric choices: Some fabrics, such as those with a high Lycra content or those that are heat-sensitive, cannot be used with heat transfer printing.

- Limited washability: Heat transfer prints are not as washable as screen prints and may fade or peel over time.

- High initial cost: The equipment needed for heat transfer printing can be expensive, making it a less cost-effective option for small businesses or individuals.

- Limited application options: Heat transfer printing is best suited for flat or mildly curved surfaces and may not work well on complex shapes or uneven surfaces.

DTG printing

DTG printing involves printing designs directly onto the garment using specialized inkjet printers. This method allows for highly detailed and complex designs, as well as the ability to print full-color images. However, it can be expensive and may not be suitable for large quantities of garments.

Digital printing has several advantages over traditional printing methods:

- Speed: Digital printing allows for faster turnaround times because it does not require the use of printing plates. This means that it is ideal for short print runs or customized materials on demand.

- Cost: Digital printing is generally more cost-effective for small print runs because it does not require the use of printing plates, which can be expensive to produce.

- Flexibility: Digital printing allows for greater flexibility in terms of the materials that can be printed on, as well as the design of the finished product. Printing on a wide range of materials, including paper, cardboard, plastic, and fabric is possible.

- Quality: Digital printing technology has improved significantly in recent years, and it is now possible to achieve high-quality prints using digital printing methods.

However, digital printing also has some disadvantages:

- Limited print run size: Digital printing is generally not suitable for large print runs because it is more expensive than silk screen printing

- Limited color options: Digital printing processes are limited to the colors that can be produced using CMYK (cyan, magenta, yellow, and black) ink, which means that it is not possible to match certain colors exactly.

- Limited durability: Digital prints may not be as durable as prints produced using traditional printing methods, especially if they are exposed to sunlight or water.

- Limited substrate options: Digital printing may not be suitable for printing on certain types of materials, such as metallic or transparent substrates.

Sublimation printing

Sublimation printing involves printing a design onto special transfer paper and then using heat and pressure to transfer the ink into the fibers of the garment. This method produces vibrant, full-color prints that are resistant to fading and peeling. However, it is limited to synthetic fabrics and cannot be used on cotton or other natural fibers.

Advantages of sublimation printing:

- High quality: Sublimation printing produces high-quality, sharp images with a wide color gamut. The prints are also durable and resistant to fading, peeling, and cracking.

- Versatility: Sublimation printing can be used on a wide range of materials, including paper, fabric, and plastic. This makes it a versatile choice for printing on a variety of products.

- Cost-effective: Sublimation printing is a cost-effective printing method, especially for large quantities of prints.

- Fast turnaround: Sublimation printing is a quick printing method, with the ability to produce a large number of prints in a short amount of time.

Disadvantages of sublimation printing:

- Limited color options: Sublimation printing is limited to a color range based on the sublimation ink spectrum. This may not be suitable for printing certain colors or shades. The result of the sublimation printing graphic will be around 90%-95% similar to your illustrator file.

- Limited material options: Sublimation printing can only be used on specially coated materials to accept the dye. This limits the range of materials that can be used with this printing method. To do sublimation printing on clothing, the composition of fabric must be 90%polyester or the colors will fade very soon. The more polyester, the better result.

- Poor results on dark fabrics: Sublimation printing may not produce good results on dark fabrics, as the dye may not show up well against the dark background. So normally we will use white or very light color fabric for sublimation printing.

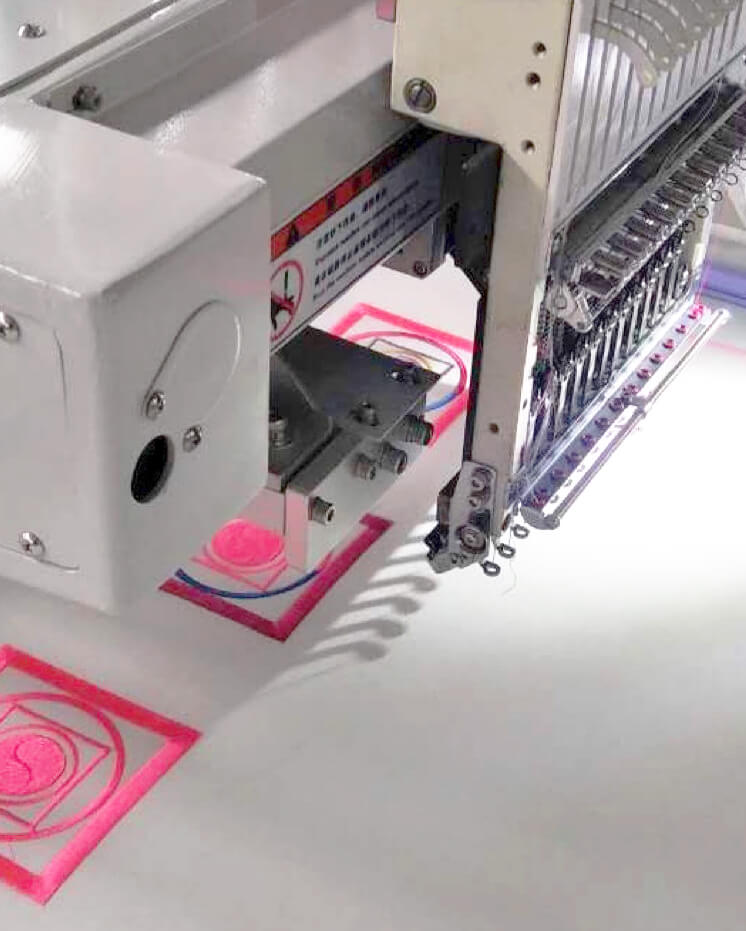

Embroidery

Embroidery is not a printing method, but it is commonly used in clothing decoration. It involves using a needle and thread to create a design on the garment. This method produces a high-quality, long-lasting finish, and it is suitable for intricate designs. However, it can be time-consuming and costly, especially for large designs or multiple colors.

Before choosing printing or embroidery for your designs, it is better to know the pros and cons of embroidery to determine if it is good enough to fit your designs.

Advantages of embroidery

- Durability: One of the main benefits of embroidery is that it is extremely long-lasting. Good quality embroidery won’t crack or fade during washing. Not only is embroidery thread strong, but it also retains its color very well. This means that the color sharpness will remain the same for the lifespan of the embroidered garment.

- Suited to Hard-To-Print-On Materials: There are some materials that you just cannot print on well, such as fleece and heavy cotton. Fortunately, embroidery is perfectly suited to these types of materials.

- Has a Quality look: The final pro for custom embroidering is that it has a high-quality look and feel. This is ideal if you want your products to have a high-end finish to them.

- Ideal for Logos: A large portion of the custom design market is taken up by the need to have logos printed. Custom embroidery lends itself perfectly to a wide variety of logos and will ensure that your branding stands the test of time on whatever product it is embroidered onto.

Disadvantage of embroidery:

While embroidery comes with a lot of pros, there are also a few cons you need to consider before choosing it for your design.

- More Costly: The first con is that embroidery is typically more expensive than printing.

- Not Suited to Some Designs: The next con is that not all designs are suited to embroidery. Small and intricate designs, very large designs and gradient designs are better not done in embroidery. It is more suitable for designs that are color blocked.

Overall, the choice of printing method will depend on the specific needs and goals of the project, including the design, quantity, and desired finish. By understanding the pros and cons of each method, you can choose the best option for your clothing printing needs.

If you are still on the fence and don’t know which to use for your designs, welcome to talk to us!