In the textile manufacturing industry, finishing encompasses the processes that are involved in transforming woven or knitted cloth into a usable material. This involves any process that is performed after the yarn or fabric has been dyed, with the aim of improving the final textile or clothing’s appearance, performance, or overall feel, which is also known as the “hand feels.”

Fabric finishing and treatments play a vital role in the creation of fabrics that possess certain qualities. For example, cotton, matte satin, silk, and other fabrics undergo specific physical and chemical procedures that enhance their softness, water resistance, or dye penetration, among other features. Ever wondered why flannel feels so soft or how fabric becomes waterproof? These attributes are largely due to the fabric finishing and treatment processes.

What is fabric finish?

Fabric finishing is the process of applying various treatments and processes to fabrics to improve their performance and appearance. This can include everything from chemical treatments to mechanical finishes. The type of finish used will depend on the type of fabric, its intended use, and the desired final result. In this article, we will look at some of the different types of fabric finishing, along with their pros and cons.

Chemical Finishing

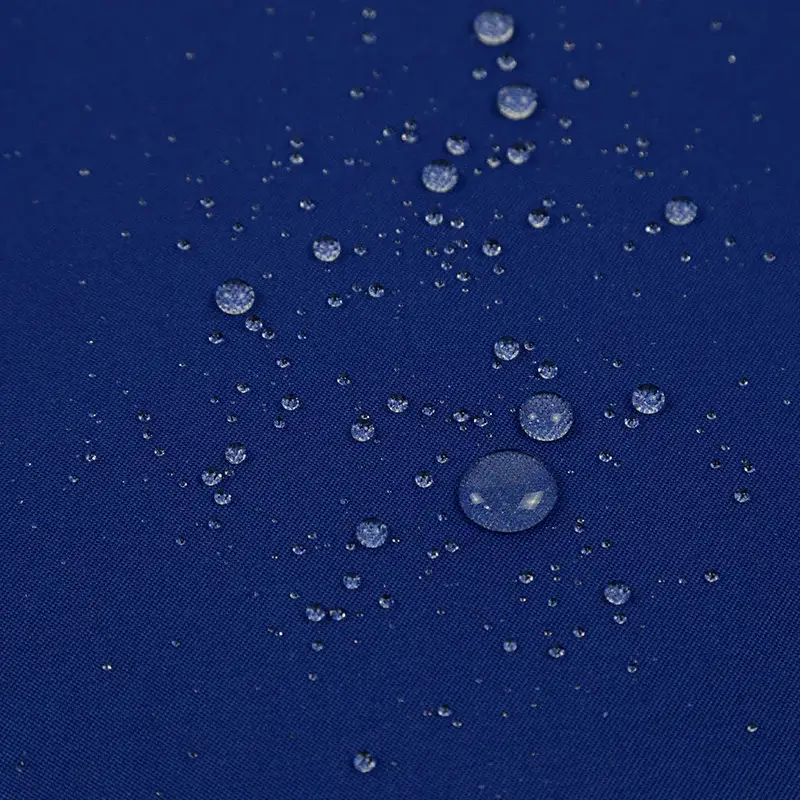

Chemical finishing involves the use of various chemicals to improve the performance and appearance of fabrics. There are many different types of chemical finishes, including flame retardants, water repellents, and anti-static agents. Chemical finishes are often used to improve the durability of a fabric or to make it more resistant to stains and damage.

Pros:

- Chemical finishes can improve the performance and durability of fabrics.

- They can make fabrics more resistant to stains and damage.

- Some chemical finishes can make fabrics more comfortable to wear.

Cons:

- Chemical finishes can be harmful to the environment and to the health of those who come into contact with them.

- Some chemical finishes can cause skin irritation or other allergic reactions.

- Chemical finishes may reduce the breathability or natural feel of the fabric.

Mechanical Finishing

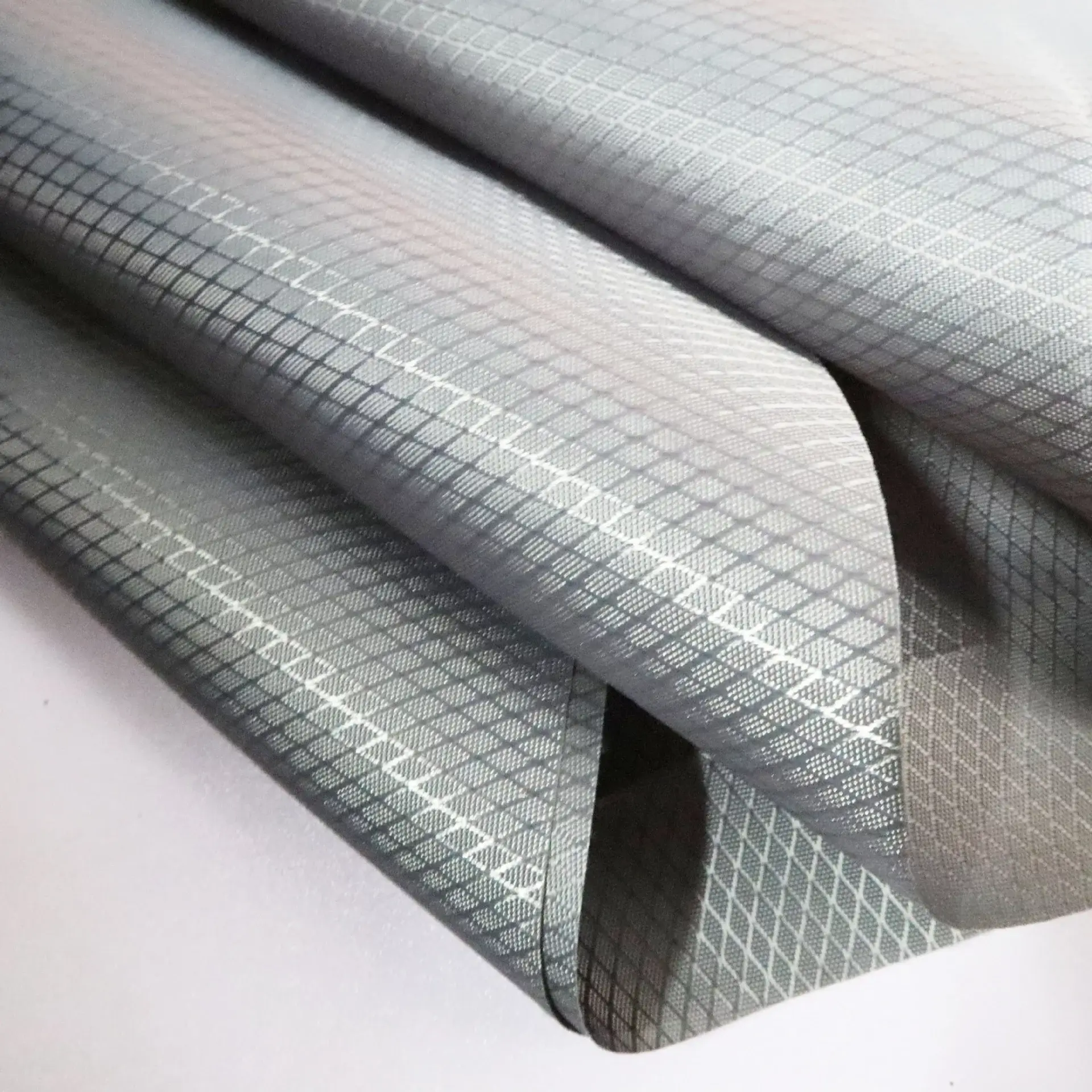

Mechanical finishing involves the use of mechanical processes to improve the texture and appearance of fabrics. This can include everything from sanding to shearing. Mechanical finishes are often used to create a specific texture or appearance or to improve the drape and flow of fabric.

Pros:

- Mechanical finishes can create unique and interesting textures and appearances.

- They can improve the drape and flow of fabric.

- Mechanical finishes are often less harmful to the environment than chemical finishes.

Cons:

- Mechanical finishes can be time-consuming and expensive.

- They may not be suitable for all types of fabrics.

- Mechanical finishes may reduce the strength or durability of a fabric.

Heat Setting

Heat setting is a process in which fabrics are treated with heat to improve their performance and appearance. This can include everything from setting the drape of a fabric to improving its color fastness. Heat setting is often used to create fabrics that are more wrinkle-resistant or that have a specific shape or texture.

Pros:

- Heat setting can improve the performance and appearance of fabrics.

- It can make fabrics more wrinkle-resistant or improve their color fastness.

- Heat setting is often a quick and cost-effective finishing process.

Cons:

- Heat setting can be harmful to some types of fabrics.

- It may reduce the breathability or natural feel of the fabric.

- Heat setting may not be suitable for all types of fabrics.

Enzyme Finishing

Enzyme finishing involves the use of enzymes to break down the fibers in a fabric and create a specific texture or appearance. Enzyme finishes are often used to create fabrics that are soft and comfortable to wear, or to create unique textures and appearances.

Pros:

- Enzyme finishes can create soft, comfortable fabrics.

- They can create unique textures and appearances.

- Enzyme finishes are often less harmful to the environment than chemical finishes.

Cons:

- Enzyme finishes can be time-consuming and expensive.

- They may not be suitable for all types of fabrics.

- Enzyme finishes may reduce the strength or durability of a fabric.

Coating Finishing

Coating finishing involves applying a layer of material to the surface of a fabric to improve its performance and appearance. This can include everything from adding a waterproof coating to creating a textured surface. Coating finishes are often used to create fabrics that are more durable or that have a specific texture or appearance.

Pros:

- Coating finishes can improve the durability and water resistance of fabrics.

- They can create unique textures and appearances.

- Coating finishes can be a cost-effective way to improve the performance of fabrics.

Cons:

- Coating finishes may reduce the breathability of a fabric.

- They may make fabrics stiffer or less comfortable to wear.

- Coating finishes may not be suitable for all types of fabrics.

Dyeing

Dyeing is the process of adding color to a fabric. There are many different types of dyes, including natural and synthetic dyes. Dyeing is often used to create fabrics with a specific color or pattern.

Pros:

- Dyeing can create fabrics with a wide range of colors and patterns.

- It can be a cost-effective way to improve the appearance of a fabric.

- Dyeing can be used on a wide range of fabrics.

Cons:

- Dyeing can be harmful to the environment.

- It may cause color fading or bleeding over time.

- Dyeing may not be suitable for all types of fabrics.

Conclusion

Fabric finishing is an important process that can improve the performance and appearance of fabrics. There are many different types of fabric finishing, each with its own pros and cons. The type of finish used will depend on the type of fabric, its intended use, and the desired final result. By understanding the different types of fabric finishing available, you can choose the best finishing process for your needs.