Direct to Garment (DTG) printing is a new technology that allows the creation of custom t-shirts quickly and easily. DTG printing works by printing ink directly onto a piece of fabric, regardless of how complex or colourful the design is.

This makes DTG printing an ideal solution for businesses or individuals who want to create custom t-shirts without having to go through the hassle of screen printing or heat transfer.

In addition, DTG printing is also much more cost-effective than other methods, making it a great option for those on a budget.

Direct Garment printing is a great option for anyone looking to create custom t-shirts quickly and easily.

How does direct to garment printing work?

To print a DTG t-shirt, you only need a computer and some basic equipment. The three primary phases of the DTG procedure are pretreatment, printing, and curing.

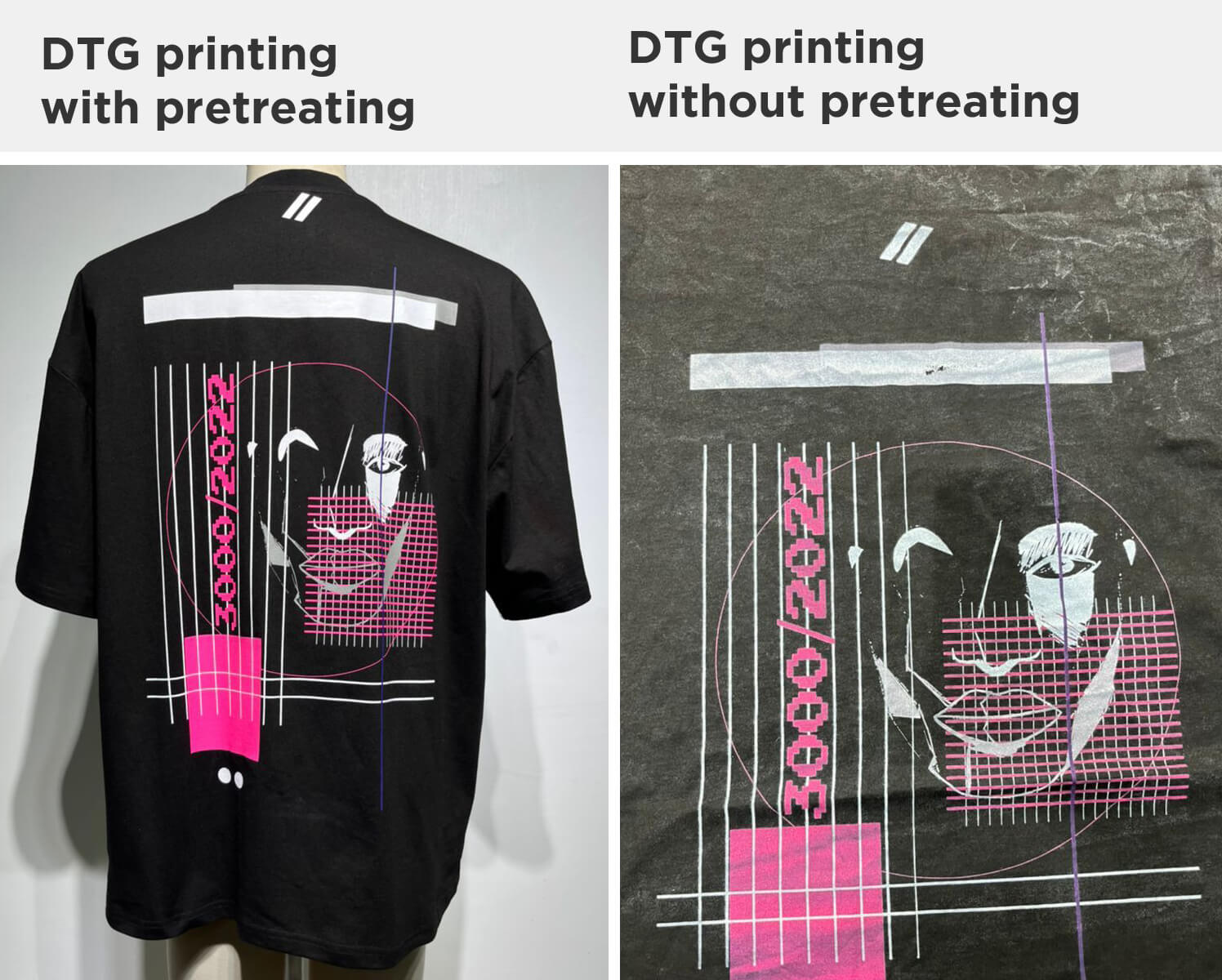

Pretreating

The shirt must first be pretreated with a solution that allows the garment to accept ink from the printer. This prevents the ink from washing off and makes the design’s colours more vibrant. The pretreatment solution can be thought of as a paint primer, which lets the fibres on the surface of

the shirt accepts ink from being printed instead of just soaking it up like a sponge.

Printing

The t-shirt is dipped in a solution and hung to dry before being placed inside the DTG printer, where it’s loaded with your digital artwork. The printer starts working once the shirt has been pretreated and dried. It initially applies a layer of white ink to increase the brilliance of the final print if it is printed on a dark-colored garment. After that, it works on the other colours on top of the white ink layer, much like an Inkjet printer. Recreating colours from your design uses a combination of cyan, magenta, yellow, and black inks. Your masterpiece is finished on the t-shirt shortly after.

Curing and Finalizing

In the following step of the procedure, we apply one final drying to ensure that the printed design is resistant to whatever may threaten it, whether it’s a washing machine or an overcautious dryer. Your shirt will be ready to wear after the curing process is complete!

Because each shirt is pretreated individually, some marks may be left over on the fabric. However, don’t worry! These usually disappear after the first wash cycle. If you want to make sure your shirt looks perfect, simply do a quick rinse in the washing machine; it should look as good as new.

What type of designs works best with DTG?

DTG or Direct to Garment printers is one of the latest technologies in the garment printing industry. This printing method is perfect for small businesses and startups because it offers them a flexible way to print their designs on t-shirts without having to order in bulk or worry about limiting the colours.

DTG uses unique inkjet technology that prints directly onto the garment in full colour. This means that businesses can order any number of shirts they need and print them on demand without having to keep stock of many different t-shirt designs and colours.

DTG also offers many colour options, which means you can print detailed designs and photorealistic images with almost no colour limitations. It makes sense to have a professional logo design service that can help you with similar logos and designs.

DTG is a great printing method for businesses that want a lot of flexibility regarding their t-shirt designs.

Is DTG printing eco-friendly?

The fashion industry is booming, but unfortunately, this success comes at a cost of increased textile waste. Each year, an estimated 92 million tons of textile waste is generated, much of which ends up in landfills.

DTG printing provides a more sustainable solution for fashion businesses, as it eliminates the need for overproduction and waste.

By allowing businesses to print one-off designs, DTG printing helps avoid excess textile waste in the fashion industry.

In addition, DTG printing is less harmful to the environment than screen printing, as it uses less water and doesn’t require chemicals. As awareness of the fashion industry’s environmental impact grows, DTG printing is likely to become increasingly popular. This eco-friendly printing method provides a more sustainable solution for businesses and helps to reduce textile waste.

The benefits of direct-to-garment printing

Short Preparation Time

DTG is the ideal printing method for small and one-off jobs because it doesn’t require much preparation work. Screen printing, on the other hand, necessitates a high level of investment in equipment, planning, and large-volume purchases for it to be profitable.

With DTG, you don’t need many garments to print – it’s perfect for small batches. Even if you’re not a computer whiz, there are no difficult configurations to be made. All you need is the garment, a printer, and some ink. This printing method is appealing because it doesn’t require much effort and usually yields a quality product.

Short preparation time also allows for great leeway in your production line. This means that time isn’t wasted constantly setting things up, and you can start printing immediately.

Straightforward Printing Process

People sometimes think operating a DTG machine is difficult, but it’s very similar to using a regular printer. The main difference is that you’re printing onto garments instead of paper. Before beginning the printing process, you should pretreat the garments with a special liquid to ensure that the ink bonds correctly.

It will only take 90 seconds to heat press the design onto the garment once it has been printed.

Vibrant and Popping Detailed Designs

To create amazing designs, DTG is a better method to use than screen printing. This is because screen printing couldn’t bring out the intricate details in a design. A lack of detail in a design would not make people want to spend money on the product.

For products to stand out among other businesses, making them detailed and popping is key. And that’s where DTG comes in to make your designs stand out from the rest.

Unrivalled Quality

DTG printing is a quick and high-quality method, making it perfect for businesses needing professional-looking uniforms or other personalized clothing. DTG ensures that intricate logos and fancy fonts always print clearly and beautifully, so you can wear your work uniforms with pride. This high-quality printing method is perfect for businesses that want to show their audience that they’re professional and established.

Flexible with Different Styles

There are plenty of industries in that DTG printing can be useful. This means that there are a lot of different markets to explore, which gives you a broad audience to reach out to. From novelty fashion to everyday clothing, DTG can broaden your product offerings.

Though it might not be your primary printing method, it’s still a great service to offer. Personalized t-shirts and other garments are always popular, and DTG allows you to welcome these orders without taking away from your main production efforts.

Showcasing your products or services to as many potential customers as possible is an ideal way to attract new business, and that’s precisely what DTG printing can help you achieve. Just be careful not to try and offer too much, or you might lose your brand’s core values in the process.

Quick Turnaround Times

We believe that DTG jobs should only be done in small batches – anything over 20 is too large of an order. The ability to quickly turn around orders without risking quality is one of the major advantages of this approach.

As buyers, we always want things to arrive as quickly as possible. Therefore, if you cannot meet demand and are good below-average turnaround times, you will likely miss out on the custom. The appearance of the site is clean and simple. It will allow you to do more with less time, allowing you to increase your productivity levels in a very short space of time. The quicker you create items, the more orders you can process. It’s never a bad thing to boost team productivity.

Environmentally Friendly

As mentioned above, DTG printing is much more environmentally friendly than other methods because you print directly onto garments. Mass wastage becomes rare as a result, meaning businesses like yours should prioritize reducing wastefulness.

How to Submit Your Design for Direct-to-Garment Printing

Use the following guidelines to create a digital version of your design:

File Format:

- Vector Files: EPS, SVG, AI, PDF

- Raster Files: PSD, TIF, PNG, JPG, PDF

Resolution:

- For the greatest print quality, use at least 300 DPI at the desired size.

Colours:

- For Direct to Garment (DTG): Unlimited colours

The recommended resolution for printing is 300 DPI, although we can make do with a lower quality if need be. However, designs that aren’t at the suggested level may turn out blurry or pixelated once printed on a t-shirt.

For best results, have your design printed on a 100% cotton t-shirt. DTG is still new technology, so it does not always print well on all types of garments.

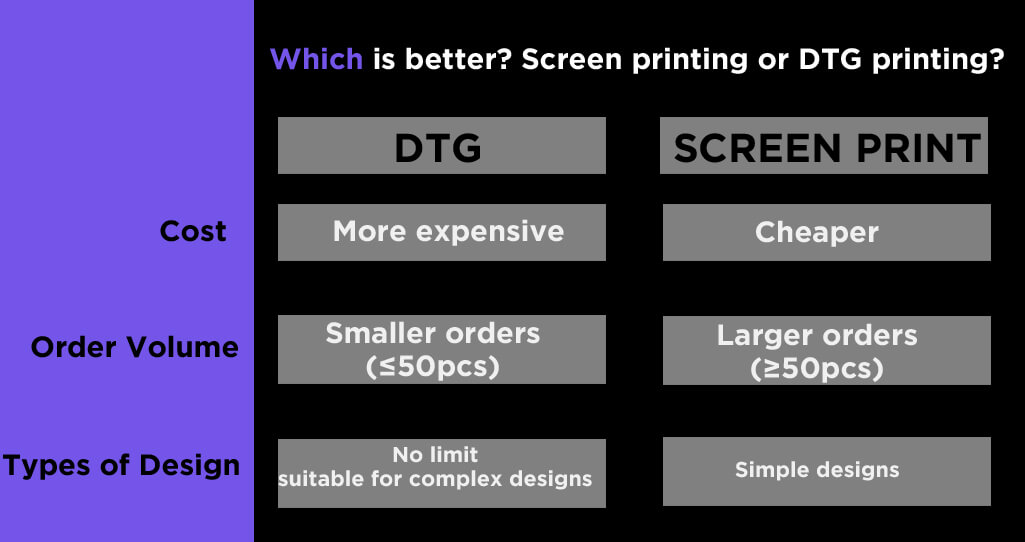

DTG VS screen printing?

Inking and finishing reduce the cost of printed goods, but they use distinct methods and price ranges. Ink is sprayed onto a garment using a printer in DTG printing, while screen printing applies ink to the top of the fabric. Most importantly, because there is no upfront investment with DTG printing, you may deliver items on demand at lower costs than traditional manufacturing processes.

Use this table to compare printing methods and decide which one is right for you:

As illustrated, there is more at stake than money and time when choosing the right printing method for your business.

Conclusion

This guide provided some clarity on the Direct to Garment printing process. This type of printing has many benefits that can be extremely advantageous to businesses, but it’s not the right method for every design. Assess your needs and research your options to ensure you’re making the best decision for your company!

Any questions about DTG printing or are interested in learning more, please contact Lezhou Garment! Our professionals would be delighted to chat with you about your specific project needs.

3 Responses

It’s interesting to know that the curing is also one of the things to look into when planning to looking into DTG printing. I’d like to know more about that because I’m thinking about getting some custom shirts produced for an event. Being able to cleanly print them will be important to ensure.

Hello Alice,

Thanks for reaching out to us 🙂

Our sales team has contacted you via email.(kathy@lezhougarment.com)

Hope to talk with you soon.

Hello Alice,

Yes, you are right, curing is very important. If it is too difficult to print it by yourself, I recommend ordering some t-shirts with your printing from https://printify.com/