In the realm of fashion, staying innovative and ahead of the curve is paramount. One revolutionary innovation making waves in the industry is the use of 3D methods in clothing design. These techniques, encompassing both printing and embroidery, add depth, texture, and visual intrigue to garments, transforming them from ordinary to extraordinary. In this article, we’ll delve into the captivating realm of 3D methods in clothing design, exploring various techniques, their advantages, limitations, and how they can redefine your designs.

Printing

High-Density Silk Screen Printing

High-density silk screen printing is a technique that involves using a thick layer of ink to create raised or textured designs on clothing. This method offers several advantages, including:

- Enhanced Texture: High-density printing adds depth and texture to designs, creating a tactile effect that stands out.

- Vibrant Colors: The thick ink layer allows for vibrant and bold colors, making designs pop.

- Durability: The raised ink layer makes designs more durable and resistant to fading or cracking over time.

However, there are some limitations to consider:

- Limited Detail: High-density printing is not suitable for intricate or detailed designs due to the thickness of the ink layer.

- Cost: The additional ink and labor required for high-density printing will result in higher production costs compared to standard printing methods.

- Not suitable for too small size logo or the logo might wash off.

Puff Printing

Puff printing is a technique that involves using a special puff additive mixed with ink to create raised designs on clothing. This method offers the following advantages:

- Textured Finish: Puff printing creates a raised, three-dimensional effect that adds texture and depth to designs.

- Customization: It allows for customizable designs with varying degrees of puffiness, from subtle to bold.

- Eye-catching Designs: The raised texture of puff printing makes designs stand out and adds visual interest to garments.

However, there are also limitations to consider:

- Limited Color Options: Puff printing may be limited in terms of color options compared to other printing methods.

- Thickness: The raised texture of puff printing results in a slightly thicker feel to the printed area and not breathable.

- The puff printing is not as durable as regular printing. The puff part will be wash-off a bit when you wash for more than 20 or 30 times.

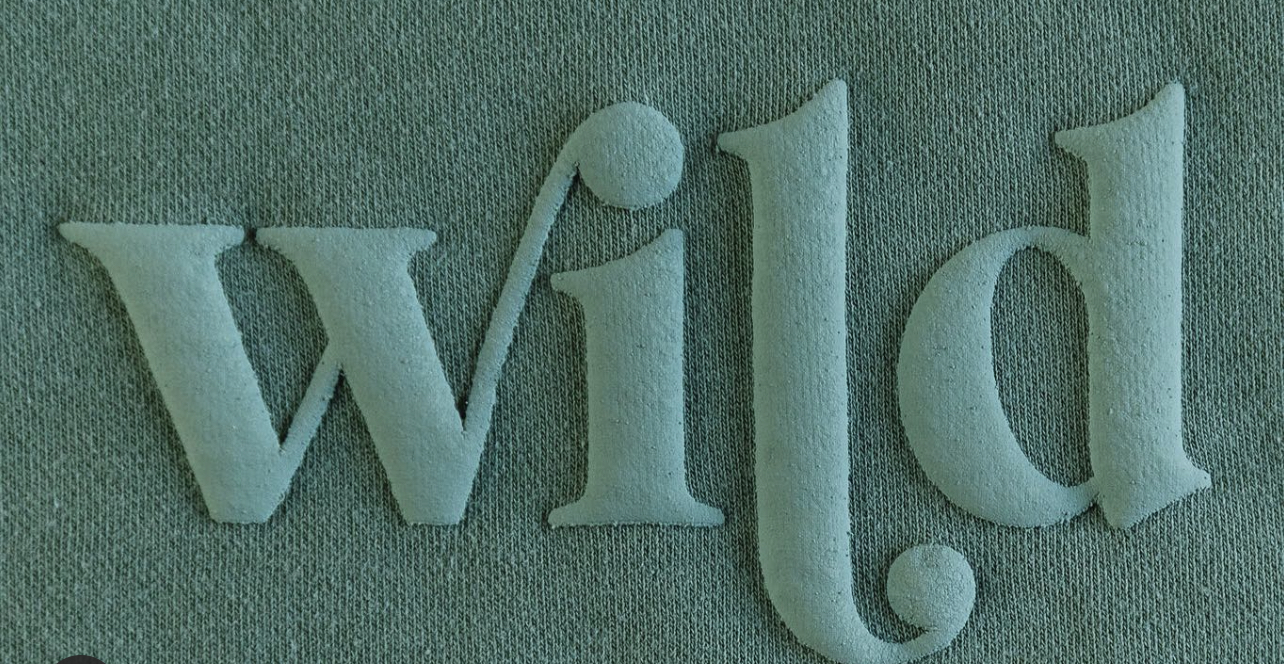

Flock Printing

Flock printing involves applying adhesive and tiny fibers (flock) to create a soft, velvety texture on clothing. This method offers advantages such as:

- Soft Texture: Flock printing creates a soft and tactile finish that feels luxurious to the touch.

- Rich Appearance: The velvety texture of flock printing adds richness and depth to designs.

- Durability: Flock printing is durable and resistant to fading, making it suitable for long-lasting designs.

However, flock printing also has limitations, including:

- Limited Detail: Flock printing may not be suitable for intricate or detailed designs due to the nature of the flock fibers.

- Special Care: Garments with flock printing require special care during washing to preserve the texture and appearance of the design. For example, machine wash cold and wash no more than 30mins or the tiny flock will disappear after washing for 10+ times.

Heat Transfer Rubber Printing

Heat transfer rubber printing involves applying a rubber-like material to garments using heat and pressure. This method offers advantages such as:

- Bold and Opaque Designs: Heat transfer rubber printing produces bold and opaque designs that stand out on garments. The rubber printing can be twice as thick as high-density printing.

However, there are also limitations to consider:

- Limited Detail: Heat transfer rubber printing may not be suitable for intricate or highly detailed designs.

- Temperature Sensitivity: The rubber material used in this printing method may be sensitive to high temperatures, which can affect the durability of the print.

- Durability: Rubber prints is not as durable and resistant as high density printing. Because the thick rubber logo is just stick on the surface of the fabric.

These are just a few of the 3D printing methods available for clothing, each with its own unique advantages and limitations. Depending on your design needs and preferences, you can choose the method that best suits your requirements.

Embroidery Techniques

3D Embroidery

3D embroidery, also known as raised embroidery, involves using padding stitches to create a three-dimensional effect on the fabric surface.

Advantages:

- Adds depth and texture to designs.

- Provides a luxurious and high-end finish.

Limitations:

- Not suitable for thin fabric. Recommend 250gsm or heavier fabric.

- Increase production time and cost.

- Not as durable as flat embroidery

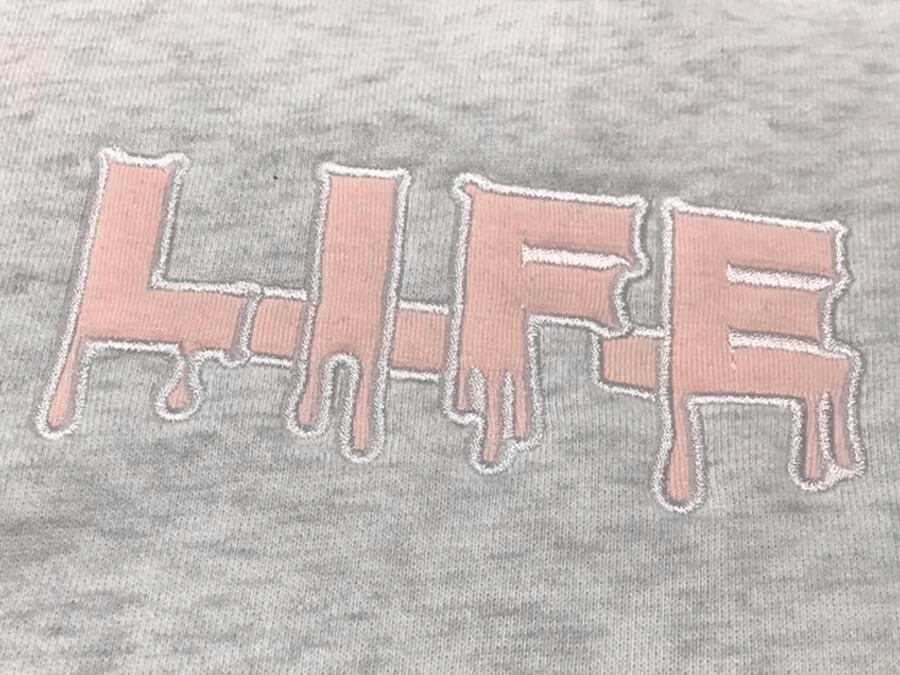

Applique

Applique is a technique where fabric pieces are stitched onto a base fabric to create a decorative design or pattern.

Advantages:

- Offers versatility in design and texture.

- Allows for the use of different fabric types and colors.

- Provides a unique and customizable look.

Limitations:

- Requires precise cutting and stitching for a polished finish.

- May result in bulkier seams depending on the fabric used.

- Take a longer time and higher cost.

Chenille Embroidery

Chenille embroidery involves using looped yarns to create a soft, textured surface on the fabric, resembling tufted chenille fabric.

Advantages:

- Creates a plush and tactile finish.

- Offers a vintage and retro aesthetic.

- Provides warmth and insulation in cold weather garments.

Limitations:

- Requires specialized equipment for production.

- Limited color options compared to other embroidery techniques.

- Higher MOQ: 500pcs per color and design

- Much higher cost and other embroidery method

Conclusion

In conclusion, the world of 3D methods in clothing design offers endless possibilities for creative expression and innovation. Whether through printing or embroidery, these techniques add depth, texture, and visual interest to garments, elevating them to new heights of style and sophistication. By embracing these techniques and exploring their advantages and limitations, fashion designers can unlock a world of creative potential and set their designs apart in a crowded marketplace.

Ready to Elevate Your Designs?

As a clothing manufacturer specializing in fully customized production, we’re equipped to bring your 3D design visions to life. With state-of-the-art printing and embroidery capabilities, we can help you create garments that stand out and make a statement. Contact us today to discuss your project and let’s bring your creative vision to reality!