Did you know that more than 90% famous clothing brands, like Nike, Adidas, Under Armour, they don’t have their own factories. 99% of their products are manufactured by garment supplier in Southeast Asia. The retailer decides everything about the product, includes design, size, material, package and everything else besides. And then the clothing will be produced by a contract or third-party manufacturer. Finally, clothing sold under a retailer’s brand name. This business model is called private label.

Apparel manufacturing, compared to electronics manufacturing, seems to be much simpler. But the production process is not at all simple than the electronics manufacturing. In this article, we will go through the complete clothing manufacturing process.

Before mass production

1. Make a tech pack

A tech pack is a document containing all the information about your clothing design. Normally it is done by your clothing designer and it includes a mock-up of your design, size chart, vector files of printing or embroidery, material & accessory list, and so on.

It’s an essential document for both designers and production teams when producing new collections, as it helps clearly communicate every little detail about what you are making, to your manufacturer.

2. Make a sample for your design

In order to verify the size, shape and fit of the garments, we have to make a finished clothing sample before mass production. Because even the same size chart will bring totally different effects when using different kinds of fabric. Let alone the shape and fit.

Especially when you are working with a new supplier, making sample should be the first thing to do after you decide to work with them. Although a factory that provides you with premium quality samples does not mean that they will deliver the same quality of clothes to you in a large production run. However, during sample production, at least you can get a sense of their work ethic, their attention to detail, their on-time delivery and whether their will communicate in a timely manner.

These factors are all as important as whether they offer you the cost-effective products.

Make bulk order

After receiving approval from you, we will start to mass production. During mass production, there are 5 main steps.

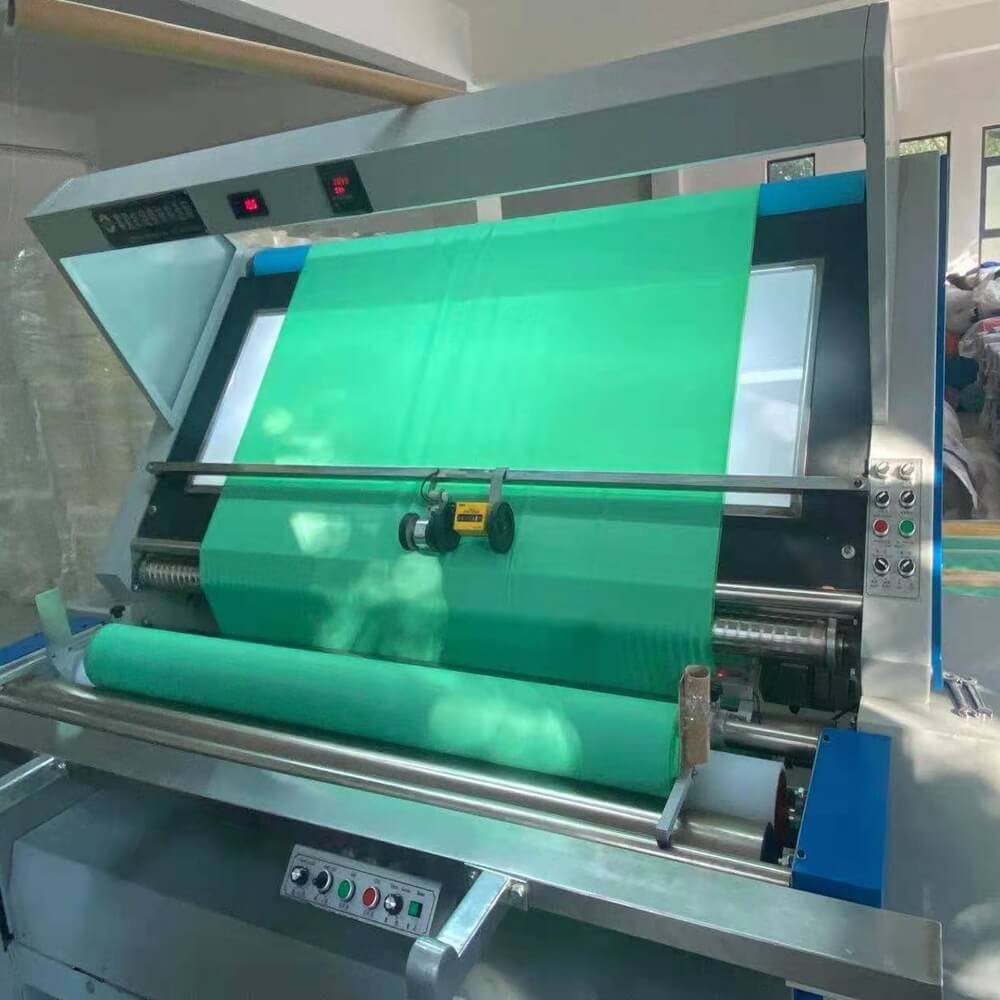

1. Pre-shrink process and quality check for fabric

First and foremost, after getting the fabric rolls from fabric supplier, we will release and check carefully meter by meter.

And then we will send the quality fabrics do pre-shrinkage treatment to minimize the shrinking problem. Unshrunk treated fabrics sometimes shrink as much as 8-10% while treated fabrics shrink normally between 1-3%.

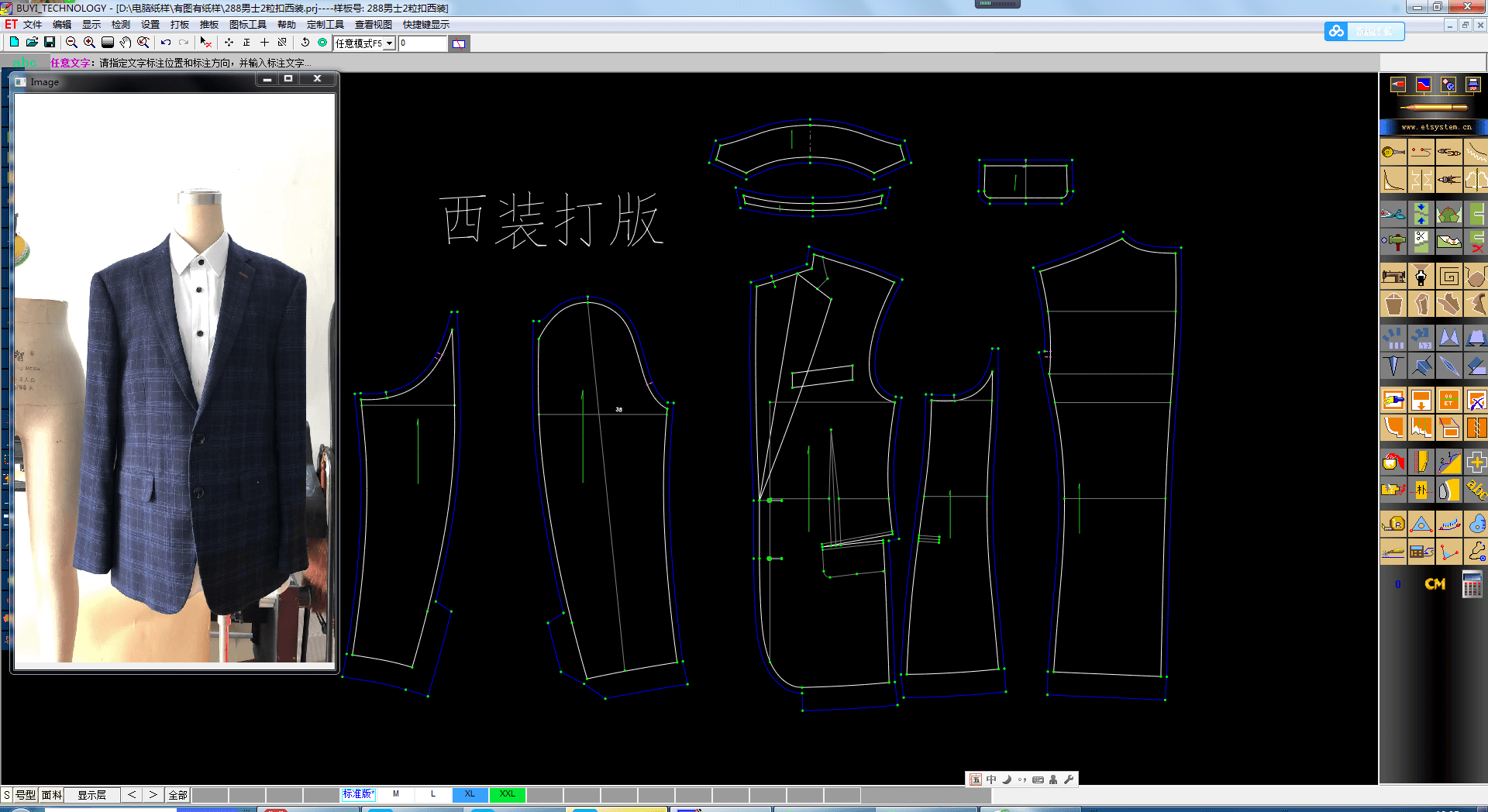

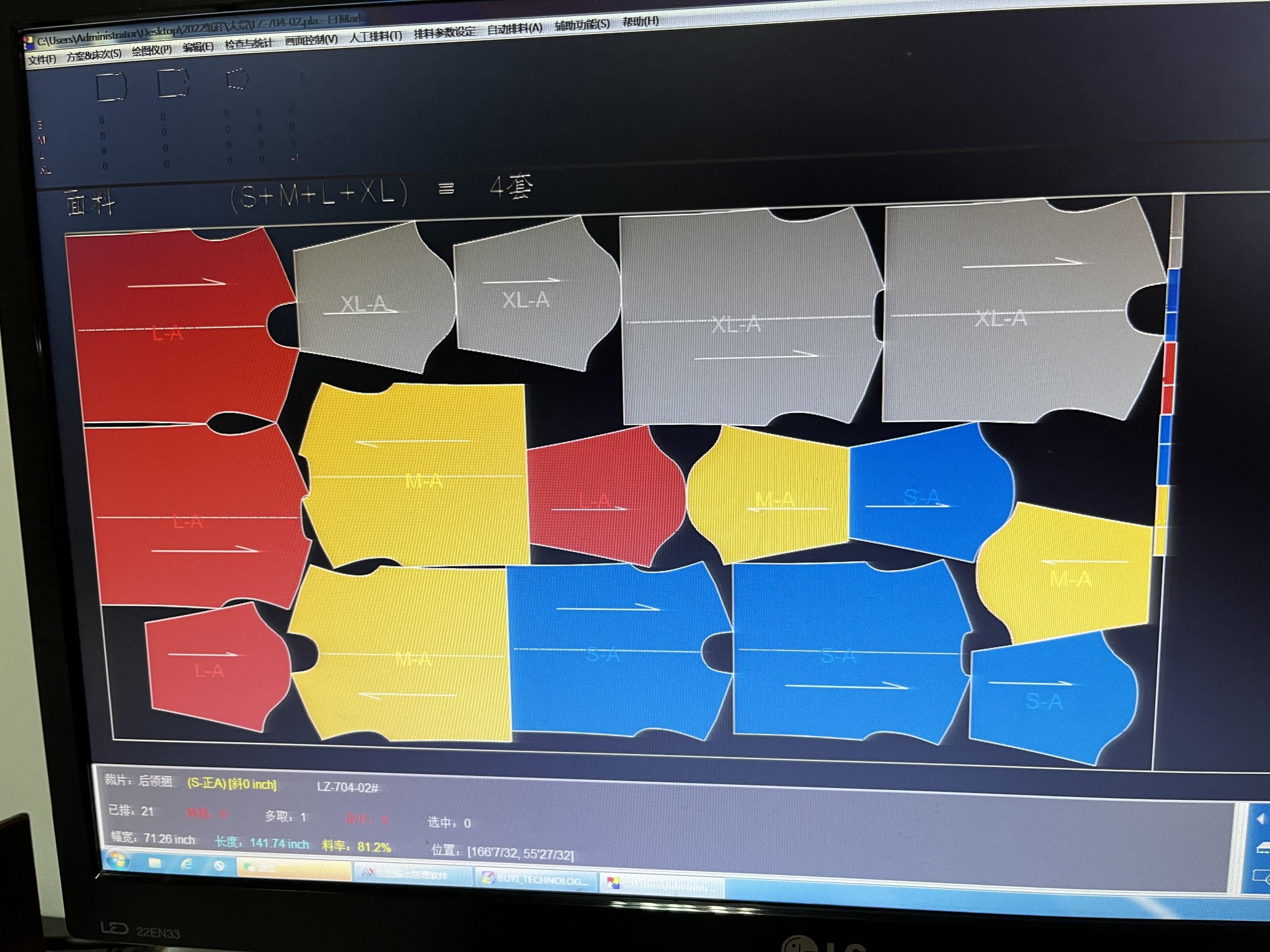

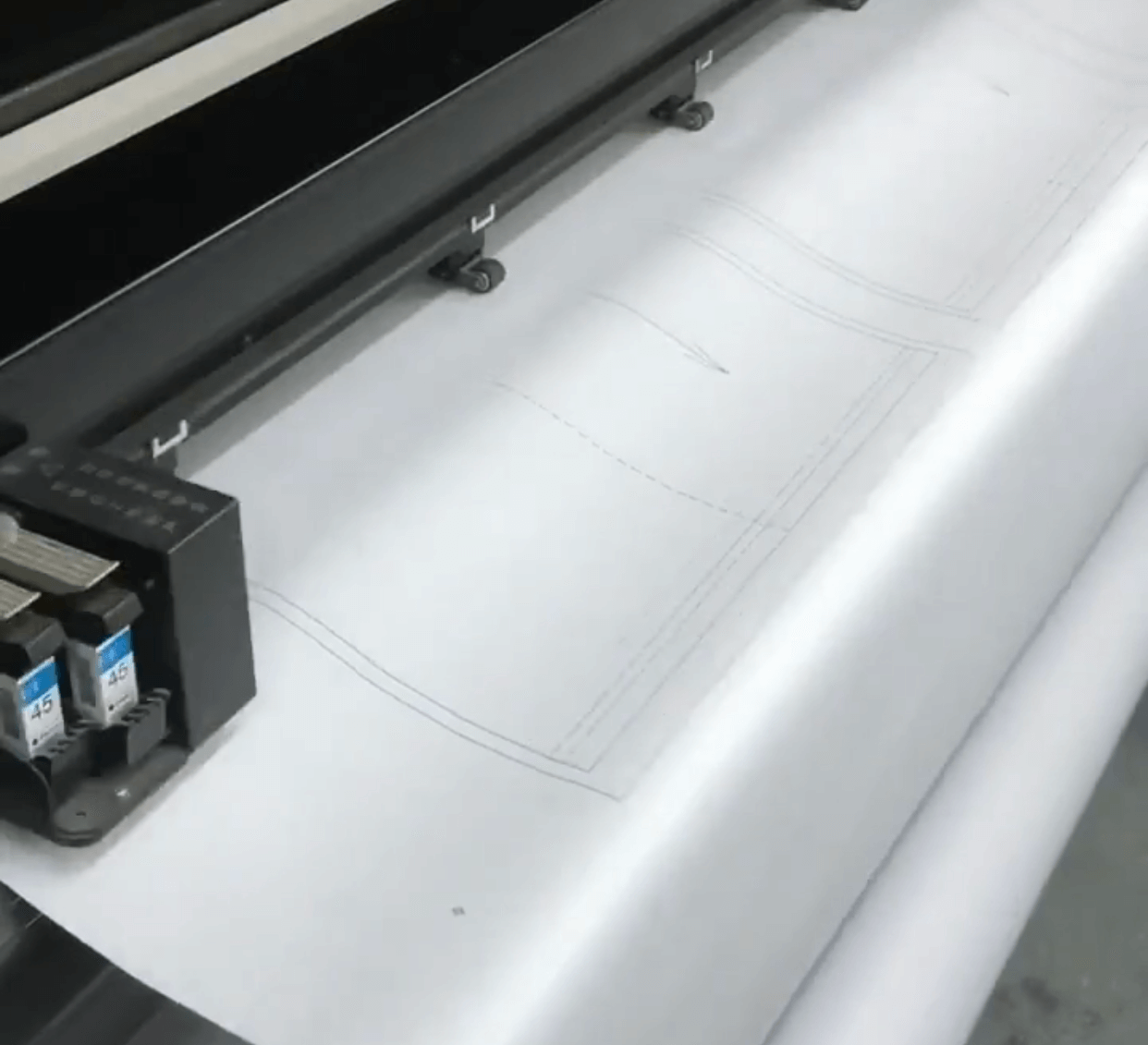

2. Size grading and paper patterns

After getting the fabric back from the shrink-treatment factory, our designer will do sizing grading according to your size chart or according to the usual practice. And then designer will lay out the paper patterns of fabric pieces according to the width of the fabric on CAD software.

Finally the paper patterns will be printed out by a big printer.

3. Fabrics laying and cutting

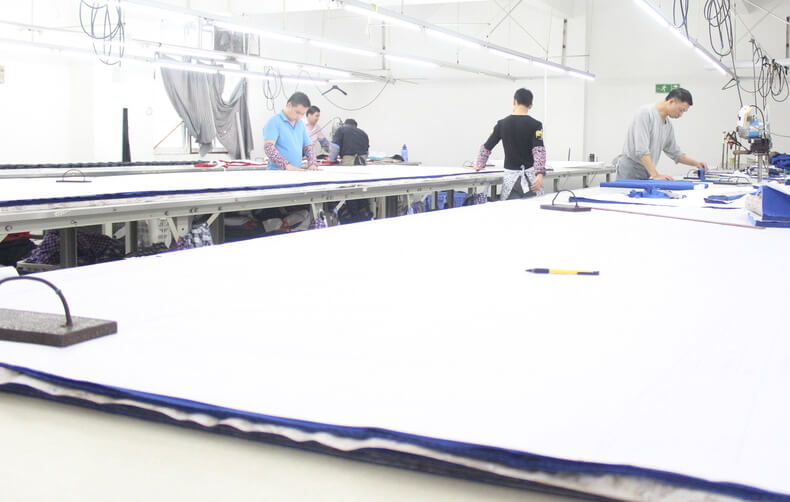

When getting the paper pattern from designer, our workmate of cutting team need to lay the fabric on the cutting bed and then put the paper pattern on the surface of fabric.

The next step is cutting fabric alone the patterns’ outline by using a cutting machine with the straight and sharp knife. It is the most crucial action. Once it is cut, there is no going back. Personally, I think it is the most interesting and exciting step during clothing manufacturing.

4. Fabric marking

After the cutting process, we will get some “fabric piles” as shown in the picture. Each “fabric piles” normally means different parts of the clothing, call cutted fabric. A garment usually consists of a few to a dozen different cutted pieces.

So another import thing our cutting workmate need to do is wrap each “piles” with a fabric tape and mark down the information of each “piles” on a small label. Only in this way, our sewing team won’t make a mistake among different cutted piece and different sizes.

5. Printing & Embroidery

Instead of printing or embroidery on a finished garment as you expected. We will add logos and graphic on cutted fabric pieces. This allows us to have maximum control over the position of the print and embroidery. Make sure that every logo on every cut piece is not skewed. On the other hand, in the process of printing or embroidering, there are always some defective pieces. It is much easier to re-cut a piece than to recreate a garment.

6. Sewing

Sewing is one of the most familiar to everyone. But did you know? Actually a piece of clothing is not exactly completed by one worker. Each worker has his or her own area of expertise. Some workers are good at overlocking while some others are good at binding. Usually, each of them is responsible for only one part of the clothing. For example, after finish sewing the collar of the shirt to the shirt body, the worker will pass it on the next one to sew the sleeves only.

Standardized processes maximize the strengths of each individual. Save cost, save time and save money.

7. Quality Checking

After sewing, we get the finished garment now. The next step is checking quality one by one. Our QC team needs to ensure correct assembly of the garment without any manufacturing flaws. This process includes checking sizes, sewing quality (skipping stitch/ needle distance and etc), printing & embroidery quality, clothing cleaning without stains.

7. Cut extra thread & ironing

When quality inspecting finish, we almost get the clothes. From the finished garment to a perfect garment. These are two important steps: cut extra threads and iron. Cutting all the excess threads brings the clothes clean and neat look. And the professional ironing can take the clothing to a higher level.

9. Package

This is the final step of garment manufacturing, we fold, add your custom hang tag, and package garments based on your requirements. We pack each clothing into protective plastic bags, then placed in carton to be ready to ship to your address.

After mass production

1. Shipping

As a full-package clothing manufacturer in China. We also offer you the logistics service include express delivery, air transportation, sea shipping and even custom clearance service if it is needed.

2. After-sale service

For the past 18 years, we have been putting product quality and customer satisfaction as our top priority. We are committed to a warranty period of up to 90 days. During this period, if there is any quality problem, we will refund your payment.

These are all the steps of clothing producing. I hope this article help you know better about clothing industry. Are you looking for a reliable clothing factory oversea? Why not contact us now. The only thing you need to do is sending us your tech pack/ design or even just some pictures of the styles you are looking for. And then we will help you to finish the rest complicated process.

2 Responses

Hello, this weekend is pleasant for me, for the reason that this occasion i am reading this enormous educational piece of writing here at my home.

Hello, thank you,hope you enjoy 🙂

We are clothing manufacturer in China. Please feel free to contact us if you need any help in this industry.