If you’re diving into the world of clothing production, you’ve probably come across various printing methods. Printing on garments is a fantastic way to showcase your creativity and bring your designs to life. In this article, we’ll explore four popular printing techniques: silk screen printing, sublimation printing, direct-to-garment (DTG) printing, and heat press printing. Each method has its unique characteristics, benefits, and considerations. So, grab a cup of coffee and let’s dive in!

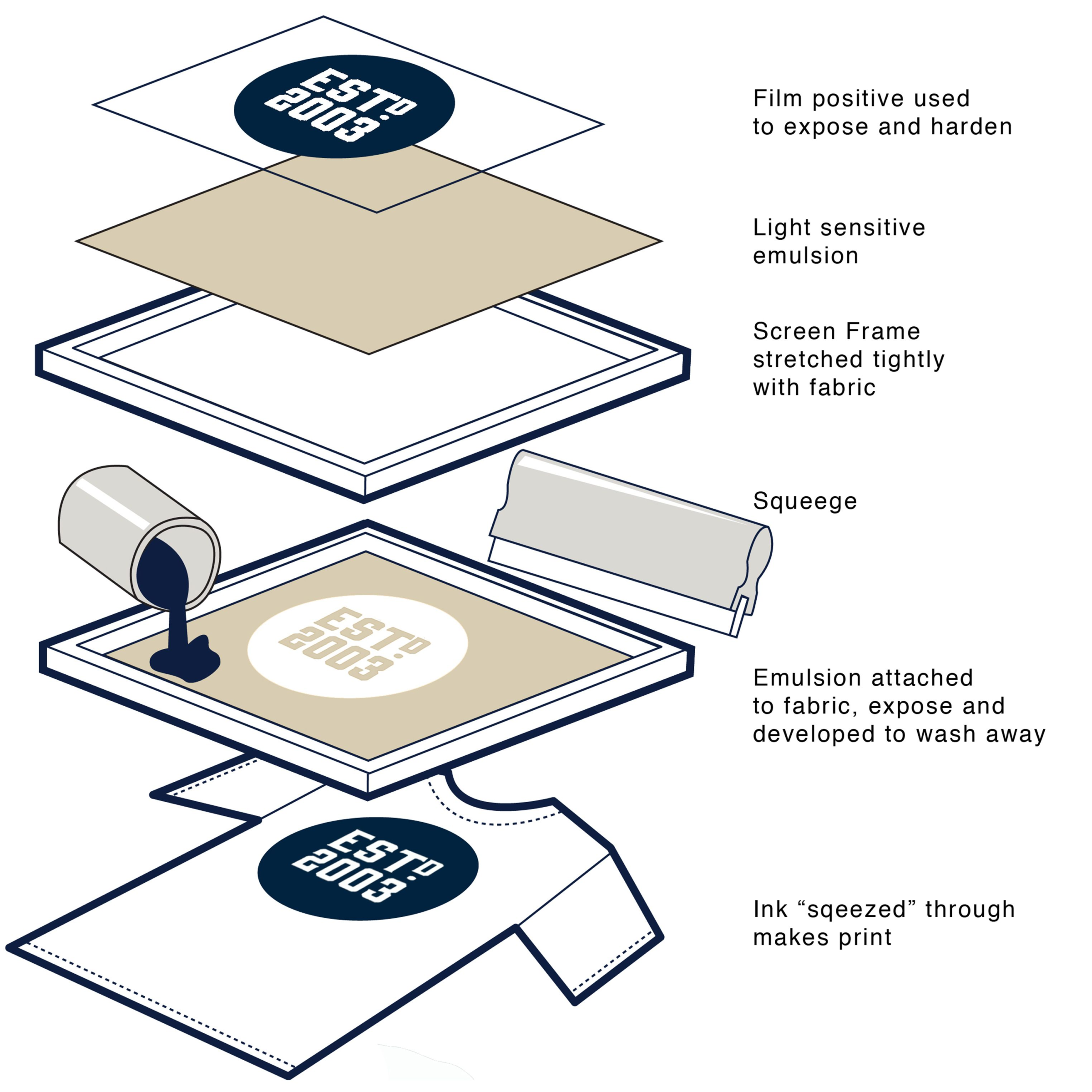

Silk Screen Printing

History: Silk screen printing, also known as screen printing or serigraphy, has a rich history dating back to ancient China. It gained popularity in the United States during the 1960s as part of the vibrant pop art movement.

Process: Silk screen printing involves transferring ink through a fine mesh screen onto the fabric. The design is created by blocking areas of the screen with a stencil or emulsion, allowing the ink to pass through the open areas onto the garment. Each color requires a separate screen, making it ideal for simple designs with fewer colors.

Benefits:

- Cost-Effectiveness: Silk screen printing becomes cost-effective for larger production runs due to lower ink costs and efficient setup.

- Durability: The ink used in silk screen printing creates vibrant and long-lasting prints that can withstand frequent washing and wear. It can be washed at least 30-50 times.

- Color Vibrancy: Silk screen printing offers excellent color vibrancy, making it perfect for bold and vibrant designs.

- Production Speed: Once the screens are set up, silk screen printing can achieve high production speeds.

Considerations:

- Fabric Compatibility: Silk screen printing works well with various fabric types, including cotton, polyester, and blends.

- Complexity: Setting up screens for each color requires expertise and precision, making it more complex compared to other printing methods.

- Design Limitations: Fine details and intricate designs is not be suitable for silk screen printing, as the process works best with larger solid areas of color.

Applications: Silk screen printing is widely used in the apparel industry for t-shirts, hoodies, jerseys, and other garments. It’s particularly popular for bulk orders, event merchandise, and promotional items.

Sublimation Printing

History: Sublimation printing emerged in the 1950s and gained popularity in the textile industry during the 1990s.

Process: Sublimation printing involves using heat to transfer dye onto polyester fabrics and other specially coated substrates. The design is printed on a transfer paper using specialized sublimation inks. Under heat and pressure, the ink sublimates from a solid to a gas, bonding with the fabric’s fibers and creating vibrant, permanent prints.

Benefits:

- Color Vibrancy: Sublimation printing produces incredibly vibrant and detailed prints with excellent color accuracy.

- Durability: The dye becomes part of the fabric, resulting in prints that are highly resistant to fading, cracking, and peeling. Sublimation printing can last forever. Color fades won’t be more than 5% even you wash it more than 50 times. The most long-lasting printing method.

- Production Speed: Sublimation printing allows for a quick production, making it suitable for on-demand or short-run orders.

- Unlimited Design Possibilities: Sublimation printing can achieve intricate and complex designs with fine details and vibrant gradients.

Considerations:

- Fabric Compatibility: Sublimation printing is primarily suitable for polyester fabrics or materials with a polyester coating, as the dye bonds specifically with polyester fibers.

- Cost-Effectiveness: Its cost is depending on how large the printing is. The larger printing, the higher price. All in all, it is much cheaper than DTG printing. Around US$1.2 each metre (bulk print) in China market.

- Limited Fabric Options: Sublimation printing can only print on polyester fabric, as the dye cannot bond effectively with other fibers.

Applications: Sublimation printing is ideal for sports apparel, activewear, and custom designs that require intricate details, such as all-over prints, photo-realistic images, and complex patterns.

Direct-to-Garment (DTG) Printing

History: DTG printing emerged in the early 2000s as a digital printing technology for textiles.

Process: DTG printing involves using specialized inkjet printers to directly apply water-based inks to the fabric. The printer sprays the ink onto the garment, layer by layer, following the design file. DTG printing allows for precise detailing and can reproduce intricate artwork accurately.

Benefits:

- Unlimited Color Options: DTG printing offers the ability to print unlimited colors, gradients, and intricate designs, including detailed photographs.

- No Minimum Order Quantity: Unlike other printing methods, DTG printing allows for printing single items or small quantities without incurring additional setup costs.

- Soft and Breathable Prints: The water-based inks used in DTG printing create prints that are soft to the touch and allow the fabric to retain its breathability.

- Fast Turnaround Time: DTG printing enables quick turnaround times, making it suitable for on-demand or personalized orders.

Considerations:

- Fabric Compatibility: DTG printing works well on various fabric types, including cotton, blends, and certain polyester fabrics.

- Cost-Effectiveness: DTG printing is the most more expensive among these 4 printings due to the higher ink costs and longer print times compared to other methods.

- Print Durability: While DTG prints can be durable, they are not as long-lasting as silk screen or sublimation prints, especially after multiple washes. Colours will fade around 5-10% after washing around 20-30 times.

- Colour: It is not as vivid as sublimation printing. DTG print can only result in a 90% similar to your printing document.

Applications: DTG printing is versatile and suitable for various clothing items, including t-shirts, sweatshirts, and baby clothes. It’s particularly popular for custom or personalized designs, limited edition releases, and one-of-a-kind garments.

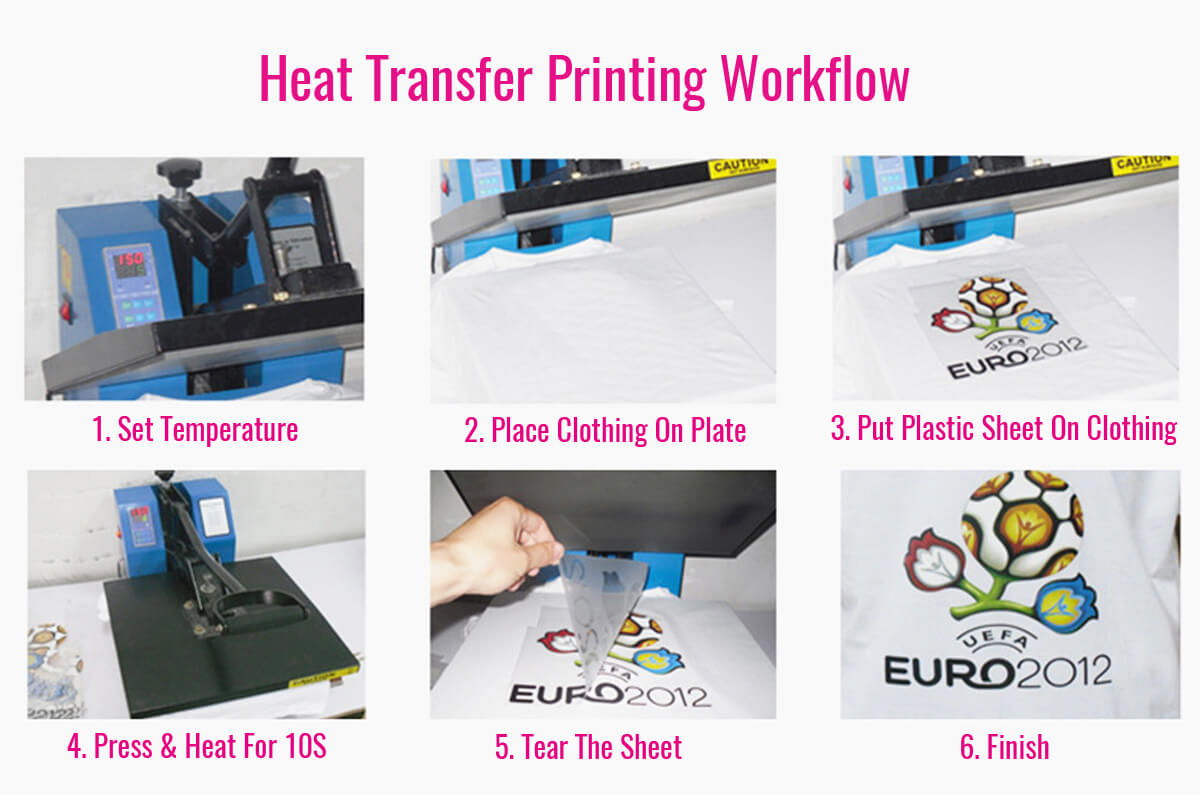

Heat Press Printing

History: Heat press printing has been around for decades and has evolved alongside advancements in heat transfer technology.

Process: Heat press printing involves applying heat and pressure to transfer a design onto the fabric using a heat press machine. The design is first printed on a transfer paper or vinyl using special inks or vinyl cutters. The transfer is then placed on the fabric, and the heat press applies heat and pressure, causing the design to adhere to the fabric.

Benefits:

- Versatility: Heat press printing allows for a wide range of design options, including solid colors, metallic finishes, and even textured effects.

- Cost-Effectiveness: Heat press printing can be cost-effective for small to medium-sized production runs, with lower setup costs compared to silk screen printing.

- Quick Turnaround: Heat press printing offers fast production times, making it suitable for on-demand or last-minute orders.

- No Color Limitations: Heat press printing allows for printing any number of colors, gradients, and even photographic images.

Considerations:

- Fabric Compatibility: Heat press printing can work with various fabric types, including cotton, polyester, blends, and even some non-textile surfaces.

- Durability: Heat press prints are not as durable as the above printing methods. It is not withstand repeated washings as well as silk screen or sublimation prints. After washing like 10 times, printing will break or peel off.

- Design Limitations: Heat press printing is not be suitable for highly detailed or intricate designs, as it relies on the transfer paper or vinyl’s resolution and cutting precision.

Applications: Heat press printing is popular for customizing t-shirts, jerseys, caps, and accessories. It’s commonly used for creating promotional merchandise, team uniforms, and personalized gifts.

Conclusion

In conclusion, choosing the right printing method for your clothing production is a crucial decision that can impact the quality and success of your designs. Silk screen printing offers cost-effectiveness, durability, and vibrant colors. While sublimation printing provides excellent color vibrancy and design possibilities. DTG printing allows for unlimited colors and fast turnaround times, while heat press printing offers versatility and quick production. Consider factors such as cost, durability, color vibrancy, fabric compatibility, complexity, and design limitations when making your choice. If you are still confused and don’t know what to do, why not talk to us? As a clothing factory with 19 years experience, I trust we can definitely solve any problems you meet in the clothing industry.