What is T-shirt

T-shirts are a type of clothing that is both durable and versatile. They can be worn as outerwear or underwear and come in various colors, patterns, and styles. T-shirt sleeves can be short or long, capped, yoked, or raglan.

Various sizes

From infants to seniors, T-shirts fit just about anyone in any size. Adult sizes are commonly classified as small, medium, large, and extra-large, while child sizes are decided by month and weight. Shirts are constructed with shoulder holes that may be buttoned with buttons or snaps to cater to newborns’ bigger heads compared to their bodies.

Versatile purposes

T-shirts are also popular garments to display one’s interests, tastes, and affiliations using customized screen prints or heat transfers. Political slogans, comedy, art, and sports, as well as renowned individuals and places, may be featured in prints. T-shirts are also a cheap way to promote companies and special events.

What Raw Materials Used for T-shirts

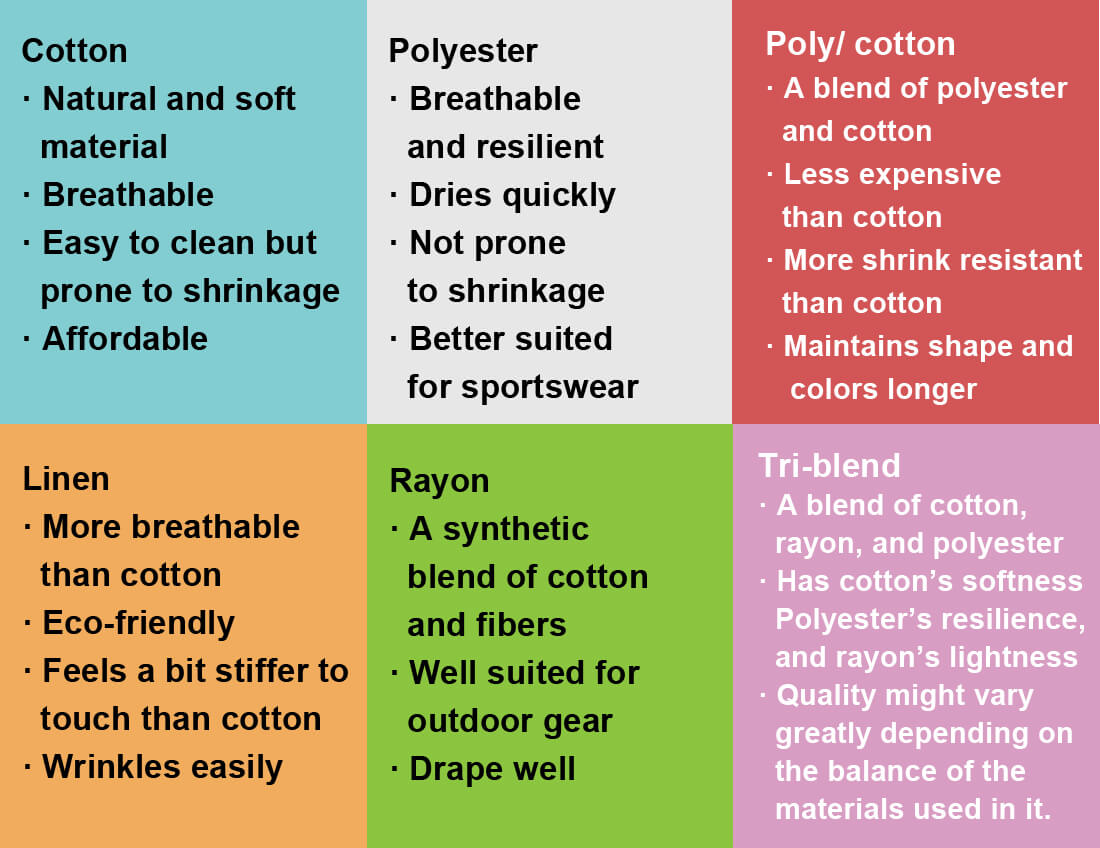

T-shirts are typically made from one of three materials: 100% cotton, polyester, or a cotton/polyester blend.

- Because of its softness, breathability, and absorbency, cotton is the most common fabric for T-shirts.

- Polyester is less absorbent than cotton but is more wrinkle-resistant and quick-drying.

- Cotton/polyester blends offer the benefits of both materials and are often used in performance or athletic wear.

- Some manufacturers use organic materials or natural dyes to be more environmentally friendly.

The Manufacturing Process

Special machines are used to cut and sew the fabric together to make a T-shirt. The most common type of seam used is a narrow, superimposed seam. This is done by placing one piece of fabric on top of another and lining up the edges of the seam.

For a more flexible finished seam, the overedge stitch is used. This requires one needle thread from above and two looper threads from below.

A bound seam is another sort of seam that may be utilized on T-shirts. This is when a narrow fabric is folded around the edge of the seam. The fabric can be stitched together using a lockstitch, chain stitch, or overedge stitch.

Depending on the style of the T-shirt, the sequence in which the garment is put together may differ.

Styling

T-shirt production generally starts with a sketch or photograph of the desired garment, which is used to create a prototype. The T-shirt design is created, and the measurements are translated into patterns. Size variances and aesthetic preferences are accommodated.

From there, a sample T-shirt is created to check the garment’s fit, fabric, color and feel. If all goes well, the design is approved, and mass production can begin.

The entire process, from start to finish, can take anywhere from a few weeks to several months.

Cutting

Cutting in t-shirt production refers to using patterns to create the individual sections that will be sewn together to create the finished garment.

Although modern t-shirts are typically made from a single piece of fabric, more traditional styles often consist of separate front and back sections, sleeves, and trim pieces.

To create these sections, a cutter will use a sharp knife or pair of scissors to follow the outline of the pattern. In some cases, multiple layers of fabric may be cut at once, which can help to speed up the production process.

Once the pieces have been cut, they will be sent to a seamstress who will assemble them into an exclusive t-shirt. Cutting is an important step in t-shirt production, and skilled cutters can play a vital role in ensuring that garments are well-crafted and fit properly.

Assembling the front and back

Seaming is an essential part of assembling a T-shirt. When done properly, it results in a strong and durable connection between the front and back sections of the shirt. It also helps to create a more finished look, preventing the fabric from raveling.

There are several ways to seam fabric, but the most common method is using an overedge stitch. This type of stitch helps to create a neat and professional-looking seam while also helping to prevent fraying. When seaming fabric, it is important to be careful not to cut the yarns of the fabric, as this can lead to tears in the garment.

Assembling the sleeves of a T-shirt

It is easier to hem the fabric flat before it is fitted into the garment. An automated system moves the sleeves by conveyor to the sewing head. The edge is finished by folding it over, forming the hem and stitching, or applying a band. The band is attached as a superimposed seam or folded over the edge as binding.

If you’re working with a tubular T-shirt body, you’ll need to sew the sleeve material together before setting it into the garment. You can set the unseamed sleeve if you’re working with a “cut and sew” T-shirt. In either case, you’ll need to sew the sleeve and side seams together during the final stage of sewing the shirt.

Stitching the hem

A well-stitched hem can mean the difference between a garment that looks professionally finished and one that looks homemade. Though it may appear to be a little detail, taking the effort to construct a tidy, secure hem may make or break the overall aesthetic of your garment.

There are a few different ways to stitch a hem, but one of the most common is an overedge stitch. This stitch allows the fabric to stretch without tearing, which is essential for garments that will see a lot of wear and tear. To create an overedge stitch, sew around the edge of the fabric with a loose tension so that the stitches can give slightly.

Another option for finishing your garment’s edges is using a combination of different stitches. This can create a decorative effect as well as added durability. Whichever method you choose, taking care to create a beautiful hem will give your garments a polished look that is sure to impress.

Adding pockets

Pockets are a common feature on T-shirts and can serve various purposes. Pockets can be ornamental or utilized to keep tiny objects such as keys or cash. In some cases, pockets may even be functional, such as when holding a phone or other electronic device.

No matter their purpose, pockets add an extra style element to a T-shirt.

When choosing a T-shirt with pockets, it is important to consider the pocket size. Smaller pockets are generally less obtrusive, while larger pockets can make it difficult to find items stored inside.

Pocket placement is also important, as front pockets are more convenient for carrying items than back pockets. Ultimately, the right T-shirt with pockets should be both stylish and functional.

Stitching the shoulder seams

There are a few different ways to stitch the shoulder seams of a T-shirt, but the most common method is known as a superimposed seam. This involves laying the two pieces of fabric on top of each other and stitching them together.

Higher-end T-shirt manufacturers may reinforce the seams with tape or elastic for extra durability. The shoulder seams may be finished before or after the neckband is applied, depending on the style of the T-shirt. For example, if a tubular neckband is to be utilized, the shoulder seams must be closed first.

No matter what method, taking care to get neat, even stitches produce a professional-looking finish.

Attaching the neckband

To attach a neckband, first, fold the band in half so that the wrong sides are together. Then align the band with the shirt’s neckline, stretching it slightly to prevent bulging. Next, use an overedge stitch to sew the band in place.

For a V-neck look, you can either attach the neckband to the neckline and then sew a tuck to form a V or overlap one side of the band over the other. Mitered seams are more complex but will create a cleaner V-neck. To create a mitered seam, an operator must overlap the band accurately and stitch the band at the center front.

Finishing the neckline

The neckline is one of the most important aspects of a T-shirt, and it can be finished in various ways. A common method is to sew a seam around the neckline, which can often be uncomfortable and prone to tearing.

Another option is to tape the neckline, which helps reinforce and prevent tearing. Additionally, the neckline can be cover stitched or top stitched, which helps to create a more polished look.

Ultimately, the best way to finish the neckline of a T-shirt depends on the intended use and aesthetic preferences. However, these methods can help create a strong and comfortable neckline that will last for many wearings.

Label setting

Labels are essential to any garment, providing important information about the manufacturer, size, fabric content, and washing instructions. In the case of T-shirts, labels are usually attached to the back of the neckline.

This is done for two reasons: first, to avoid discomfort for the wearer; and second, to prevent the label from interfering with the print on the front of the shirt.

There are various methods for attaching labels to T-shirts, but the most common is using a heat-sealed adhesive. This method provides a strong bond that can withstand repeated washings. Other methods, such as sewing or ironing, can also be used, but these are not as durable and may come detached over time.

Optional features

T-shirts can be produced with various features to meet the needs of different customers. Some T-shirts come with trim or screen prints for decorative purposes. Others have larger openings at the head to make it easier for infants to wear them.

The shoulder seams on some T-shirts are left open near the neck, and buttons or other fasteners are attached to make them more comfortable to wear.

In addition, T-shirts can be made from various materials to meet the needs of different customers. Some T-shirts are made from cotton for a soft feel, while others are made from polyester for a more durable shirt.

Finishing operations

To ensure that T-shirts are of high quality, manufacturers inspect them for fabric, stitching, and thread flaws. If a T-shirt meets high standards, it may be pressed with steam before being packaged. The packaging process depends on the type of T-shirt and where it will be sold. For example, underwear is typically folded and placed in pre-printed bags that list information about the product. Shirts may also be boarded or folded around cardboard to keep their shape while shipping and on store shelves. Finally, T-shirts are usually placed in boxes by the dozen or half-dozen. Various quality control measures are in place for the clothing industry in general and specific standards for the T-shirt industry. These include proper sizing and fit, appropriate needles and seams, types of stitches, and the number of stitches per inch. In addition, T-shirts must be inspected to ensure that necklines are flat against the body and recover properly after being stretched. Hems must also be flat and wide enough to prevent curling.