Introduction

Ever since man began to exist, he has known colour. Nature is like one big work of art, always providing new colours and compositions that inspire man to use them in his own way – whether painting on cave walls or wearing dyed fabrics. In the beginning, primitive man coloured the caves and smeared himself with pigment from what he found around him. Eventually, ancient people learned how to extract dyes from different sources such as roots, stems, leaves, fruits, berries etc., which they then used to dye cloths.

Throughout history, colour has been an integral part of human life. The changing colours of nature with the seasons were one of the first sources of inspiration for early artists and were needed centuries ago. People have always liked adding colour to everyday items, especially clothes. So they extracted dyes from different natural sources such as plants, animals, insects and minerals and applied them to the fabric. The quest for new shades led to the discovery of synthetic dyes, which eventually became a full-fledged industry.

Classification of Dyes

Dyes have two parts: the chromophore, which gives colour, and the autochrome, which affects how well the dye sticks to things. Dyes can be natural or synthetic.

Natural Dyes

Natural dyes are substances used to colour textiles from natural sources. People depended on natural dyes for centuries until synthetic ones became prevalent in the mid-19th century. While cheaper and possessing excellent fastness properties, artificial dyes lost popularity due to consumers’ growing realisation of their harmful effects and increasing environmental awareness and striation laws.

Advantages of Natural Dyes

- Natural dyes protect our environment because they come from sustainable sources.

- Generates calming and pleasant colours

- UV rays are filtered by these dyes, and they help to keep the colour vibrant.

- Because natural dyes have anti-microbial properties, they safeguard the fabrics and wearers from microbial infestation.

- Many natural dyes can double as both mosquito repellent and flame retardant.

- Because they come from rich sources in a specific area, the raw materials will always be available, and transport costs will stay low.

Disadvantages of Natural Dyes

- It’s more difficult to keep natural dyes on hand.

- Dyes may fade quickly in sunlight.

- Colours may bleed or run when the fabric gets wet.

- Extracting dyes from fabric is a time-consuming procedure.

- It’s difficult to reproduce the same colour tone.

- Natural dyes are free of impurities, which means the colour they produce fades over time.

- The dyes’ colours are dictated by the time of year.

- Standardizing the complicated natural dyeing process is difficult.

Classification of Natural Dyes

Dyes can be separated into three categories depending on their source:

- vegetable dyes,

- animal dyes,

- and mineral dyes.

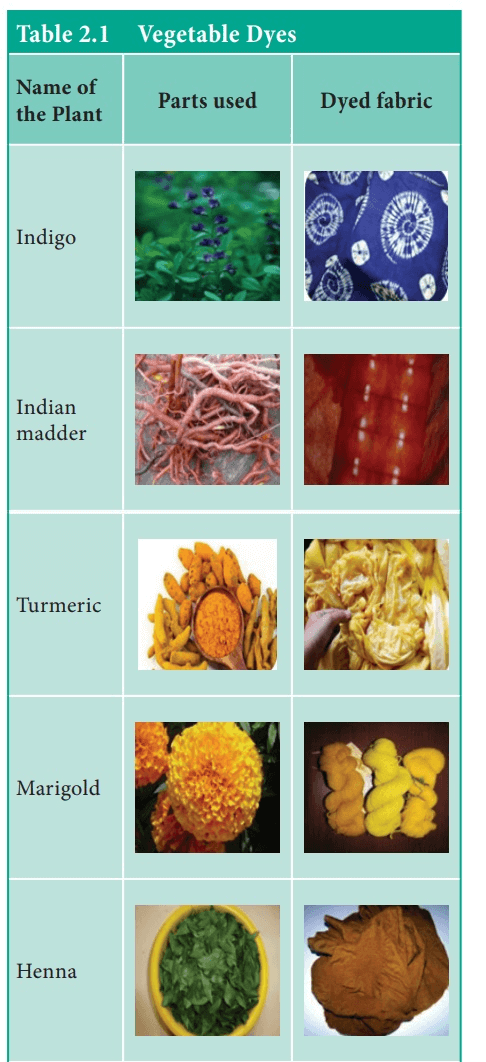

Vegetable Dyes

Some of the earliest discovered dyes originated from vegetables, as people would accidentally stain their clothing with fruit or plant juices. Vegetable dyes can be taken from different parts of plants, such as leaves, flowers, fruits, pods, bark etc., and applied either directly or with mordants.

Indigo

Indigo is a blue dye that can be derived from the leaves of the leguminous plant Indigofera tinctoria. This natural dye is perfect for colouring cotton and wool fibres.

Indian Madder

Rubia tinctoria roots have a red pigment that can be used to colour fabric. It’s used to dye cotton and wool fabrics. Rubia tinctoria roots are the source of the pigment.

Turmeric

The turmeric root (rhizome) is ground to produce a yellow dye, which can be used to colour cotton, silk and wool fabrics.

Marigold

This particular shade of yellow is extracted from marigold flowers. It can be used to dye both silk and wool fabrics.

Henna

Lawsonia inermis leaves are crushed and used to make the red colour. It gives an orange hue. It may be used to dye wool and silk fibres.

Tea

Brown dyes can be produced by leaves of tea plants (Camellia sinensis) or tea powder. These dyes usually produce a range of different shades of brown.

Onion

The outermost skin of the onion can be used as a dye. If dried properly, it can last up to one year.

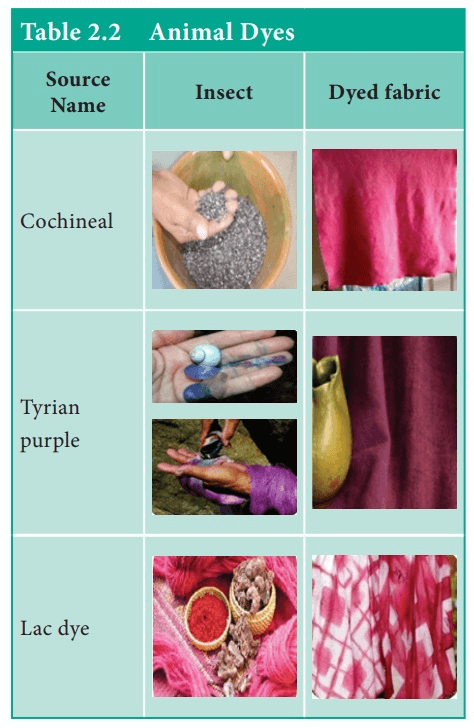

Animal Dyes

Animal dyes are dyes obtained from invertebrates such as insects and snails. Animal-derived hues of red and purple were discovered. Animal dyes include Cochineal, Tyrian purple, and Lac.

1. Cochineal

Cochineal dye is often derived from female red bugs’ carcasses (Dactylopius coccus). This process usually creates crimson and scarlet colours used to colour wool and silk. Aluminium and tin oxide mordants are typically used in this dyestuff, resulting in much brighter hues. Finally, this type of dyeing provides fabrics with excellent fastness properties.

2. Tyrian Purple

The colour of this pigment comes from the sea snails that can be found in the Mediterranean Sea. Because only a small amount of dye was available, it became quite costly. As a result, it is known as Royal purple.

3. Lac Dye

The lac insect (Lauifer lacca) secretes a fluid that can be used to extract dyes in shades of crimson and scarlet. These dyes tend to be colourfast, meaning they won’t fade easily with washings or exposure to light.

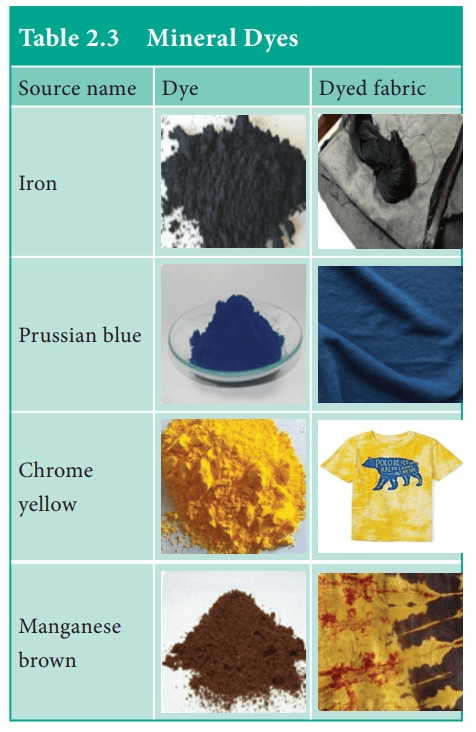

Mineral Dyes

Commercial dyes are not made from minerals because they can be poisonous. The most widely used mineral dyes, which come in shades of yellowish brown, chrome yellow, Prussian blue and manganese brown, are extracted from iron.

Synthetic Dyes

Dyes can be synthetic or naturally occurring. Synthetic dyes are made from chemicals and classified based on their chemical composition.

1. Direct Dyes

Direct dyes are water-soluble and do not require a fixing agent to colour fabric. Producing direct dyes is easy, as well as applying them inexpensively. Direct dyes are also anionic, giving cellulosic fibres greater affinity. Bright shades can be produced with direct dyeing without using a mordant, giving you a wide range of colours for your project!

Sodium carbonate is used to level the dye. An exhaustion agent such as salt (NaCl) is added at the end of the process to assist the colour in moving out of the liquor and adhere to the fibre. Direct dyes are used on wool, silk, and nylon fabrics. Direct dyes may be used on various textiles, including clothing, upholstery fabrics, draperies, linings, and auto-upholstery fabric. Most direct dyes have good resistance to light but poor wash fastness.

2. Reactive Dyes

Reactive dyes are chemicals that react with the fibres and form covalent bonds. They become an essential component of the fibre. They’re soluble in water and used to colour cellulose, protein, and polyamide fibres. They have a wide colour range and high brightness. The dyeing of fibre using reactive dyes occurs in three stages: exhaustion (salt or Glauber’s salt), fixation (sodium carbonate or sodium hydroxide), and rinsing (sodium carbonate or sodium hydroxide).

3. Basic Dyes

Dyes are a type of pigment made from synthetic chemicals. Dyes are distinguished by the nature and quantity of their anionic groups, which may be cationic or basic (positively charged). The acidic components in the fibres react with basic dyes to form electrovalent bonds. Basic dyes are soluble in alcohol but not easily so in water. The colours obtained by basic dyes are much more brilliant than those produced by other dye classes.

Basic dyes work best on wool, silk and acrylic fabrics but will not stick to cellulose fibres. To use basic dyes on cotton, linen, acetate, nylon or polyester fabrics, you must first treat the fabric with a mordant. Basic dye colours are also of moderate lightfastness and colourfastness to washing. To prepare the dye bath, mix an equal amount of dyestuff with acetic acid before adding warm water while stirring constantly.

4. Acid Dyes

Acid dyes are water soluble and require an acidic substance, such as sulphuric or acetic acid, to dye silk or wool. These Acid dyes usually come in sodium salts or organic acids. When dissolved in water, they produce negative ions (anions or acidic groups), which react with positive ions on protein fibres and bind to the fibre through electrovalent bonds.

Acid dyes, similar to direct dyes, can only be applied to certain fabrics due to structural variations. For example, they work better with protein and polyamide fibres than with cellulosic fibre. In addition, they are known for being very colourfast and inexpensive.

5. Mordant or Chrome Dyes

Natural dyes and some synthetic dyes are not absorbed by fibres. They can be dyed with the aid of various chemicals. Mordant dyes, also known as mordant dyes, are chemicals used to dye fibres. A mordant dye has an affinity for fibre and colouration, creating a connection between the dye molecule and the fibre.

6. Disperse Dyes

Disperse dyes are water-insoluble. However, their solubility can be raised with dispersing agents and higher temperatures. They work best on synthetic fabrics that don’t absorb liquids well, such as nylon, polyester and acrylic. Also, dispersed dyes are non-ionic or neutral, giving them excellent resistance to washing and sunlight exposure.

7. Vat Dyes

Vat dyes got their name from the large wooden vessels, called vats, in which they were first fermented. These dyes cannot dissolve in water but are soluble in alkalis. Vat dyes enter the fabric in a reduced or deactivated form and permanently attach to the fibres when oxidized. To turn them into leuco compounds–which can be dissolved by alkalis–the dye is treated with a reducing agent.

The process of mixing the dyes with solvent is referred to as vatting. The leuco compounds are either colourless or have a distinct hue from the final product, which is produced by oxidation. After dyeing the fibre, it becomes oxidized and forms an insoluble colourant that lodges inside the strand. Indigo, a type of vat dye, has been used in India for a long time.

Vat dyes in a soluble form have a great affinity for cellulosic fibres. They’re the fastest dyes available for cotton, linen and rayon. They can be applied to wool, nylon, polyester and acrylics with a mordant. Furthermore, vat dyes are resistant to light exposure, acids and alkalies.

The basic principles of vat dye application can be summarized as follows:

- The insoluble vat dye is reduced or “vatted” to become the soluble leuco form.

- The reduction of the dye’s solubility results in the fibres being dyed.

- The soluble dye is converted to the insoluble state by oxidation after absorption.

- To produce an accurate and enduring colour with maximum durability, treat the dye or printed material in a hot detergent bath.

8. Sulphur Dyes

Sulfur dyes, like vat dyes, have a distinct feature: they are water-insoluble and can be made soluble by adding reducing agents and alkalis as solubilizers. They may also be prepared using sodium sulphide or sodium hydrosulphite as a reducing agent to form soluble leuco compounds. The cellulosic fibres have a strong attraction for leuco compounds.

Sulphur dyes produce colours such as navy blue, black, khaki and olive green. They are mainly used for black more than any other colours because they have excellent wash fastness properties. However, the fabric loses its softness after dyeing with sulphur dyes.

9. Azoic Dyes or Naphthol Dyes

The azoic dyes are made rather than stored as dye substances, and they must be generated directly in the fibre using the proper proportions of their components. When naphthol is combined with sodium hydroxide at room temperature, it gives a colourless or pale yellow or brown colour to cotton.

When dyed with a mentholated base in the second bath containing acid and sodium nitrite at ice-cold temperatures, the fabric produces a bright colour which is insoluble in water. The two components form an azo group during coupling to produce the dye. This type of dye is known as an azoic dye since it is formed inside the fibre. It is also called an ingrain dye because it penetrates into the fabric fibres. Azo dyes are sometimes called ice colours because their application involves using ice to lower the temperature.

Azo dyes are used on cellulosic fibres and have only recently been discovered to be effective on acrylic, nylon, and polyester. Azo dyes are vivid in hue. They resist washing well and can be lightly faded with a clothes brush or damp towel.

10. Pigment Dyes

Pigments don’t count as dyes because they don’t stick to fabric fibres. Instead, adhesives and resins hold pigments onto the fabric’s surface. Dope dyeing and printing usually utilize pigments instead of dyes since it’s quicker and cheaper. When applied to fabric in a dissolved state, we call it a vat dye; however, when employed in an insoluble form using binding agents, it classifies as a pigment. Out of all the available options, pigment dyes boast excellent lightfastness properties.

11. Optical Brighteners

These dyes are popular among people who want a brighter, whiter look for their clothes. They work by absorbing light in the UV region and emitting blue light in the visible region. You can apply them during bleaching or as part of the final finish. These dyes are affinity for cotton but can also be used on wool, nylon, acetate and acrylic fabrics.