Need help with measuring for the perfect fit in apparel? Don’t worry; there’s no need to waste time trying to decipher complex instructions; learning how to correctly measure for apparel is a lot easier than most people think! With a few simple tips and tricks, you’ll be able to accurately measure all your clothing needs like a pro. So what are you waiting for? Let’s get measuring!

The Vitruvian Man

Leonardo da Vinci’s famous drawing of the Vitruvian Man is an instruction manual for anyone interested in measuring apparel. After all, that iconic pose is nothing short of a fashionista’s playbook – whether you need to determine if that hat or blazer will fit, just find the closest person and measure them against the masterpiece! We may have to forgive da Vinci for his apparent lack of color coding regarding measurements!

How Did Measuring Start?

Measuring apparel has been around since the dawn of clothing itself. The history of apparel measurement is almost as old as one’s imagination–and it’s exciting to explore! Measuring apparel began with rudimentary common measurements like neck circumference and sleeve length. Body measurements have evolved drastically from ancient times to the modern day to become increasingly precise and accurate.

Middle Ages

- The first recorded examples of clothing measurement date back to the Middle Ages, when people would measure themselves with a rope or string before ordering a garment made by tailors. However, these measurements were far from the standard ones used in today’s industry.

- During this time, measuring apparel was relatively straightforward—a loop of string or rope wrapped around your waist or chest would tell you how long a dress should be hemmed for you. Although this process could get somewhat accurate results if done precisely, there was still plenty of room for error at that time due to the lack of standardization among different tailors and measurements being taken by hand.

1700s

- In the 1700s, for example, it became famous for men competing in fencing tournaments to wear specially tailored clothing that fitted them perfectly, giving birth to the first use of what we now consider standard measurements for garments! This practice eventually spread further into society and became commonplace for anyone wishing to buy custom-made apparel. As time went on, more sophisticated methods such as calipers and rulers were developed to get more accurate measurements – slowly yet indeed leading us closer to what we know now as “standard” sizes utilized in both ready-to-wear and bespoke garments alike.

Mid-1900s

- By the mid-1900s, international sizing systems had solidified themselves into everyday life all over the world thanks mainly in part due to advancements in technology that enabled makers and consumers alike access better equipment to obtain exact sizing information without having a lot of input from said participant wearing it, e.g., 3D body scanners, which made collecting data more accessible than ever before!

Nowadays

- These days measuring apparel has become an art form; many companies hire experienced professionals who specialize in taking perfect body measurements so individuals can feel confident about their size when shopping clothes online or at physical stores.

- The evolution of measuring apparel has come full circle from ancient times, demonstrating how far humankind has come to understand our bodies!

Why Measurements Matter When Manufacturing

The fit of the garment

With the proper **clothing sizes** outlined, your product will fit properly. And the fit of the garment is one of the most important selling points for any apparel. Measuring correctly ensures that clothes hang and drape naturally, giving customers a good feeling when they try them on. That can help increase sales and boost customer satisfaction because they know they’re getting something that will look and feel perfect on them.

Enough materials supply

And accurate measurements aren’t just important to ensure perfect fits – it’s also essential to ensure enough materials to cover all sizes. If you accurately understand what styles work best for different body types, you may end up with less or not enough fabric for certain sizes and have to order more. This means more money and time wasted – two things you want to avoid dealing with when attempting to manufacture products at scale efficiently.

In conclusion, apparel measurements matter immensely when manufacturing garments. They dictate how well the clothing will fit, how much material is needed, and even which body types might prefer certain styles over others. By taking measurements into account throughout the entire design process from start to finish, companies can save time, money, and resources while optimizing their apparel before launch day arrives – giving customers a product that looks good on anyone who tries it on!

How To Determine Measurements

Taking accurate measurements for your new clothes is essential to breast the tape and stand out from the fashion crowd. After all, there’s nothing more embarrassing than buying a sweater two sizes too large or a pair of pants that won’t fit around your thighs. Determining apparel measurements doesn’t have to be daunting; it can be straightforward with just a few essential tools.

Here are some helpful tips for determining apparel measurements like a pro.

- To start with, you’ll need a flexible measuring tape for tailoring or sewing. It should even have both metric and imperial units printed on it, so you don’t have to worry about conversions when trying to find accurate measurements according to the product size guidelines stated by clothing brands.

- Next, wear clothing that only adds a little bulk when taking the measurements. Nothing too thick or baggy can give you skewed numbers and leave you with ill-fitting garments.

- Once everything is set up and ready, take your measurements one by one: chest circumference, waistline, hips (or hip and buttock circumference), sleeve length, thigh circumference, and pant length. For best results, always use the measuring tape by keeping it snug against your body without compressing your skin.

- Finally – and perhaps most importantly – write all these numbers down! You certainly don’t want to forget what they are after spending time taking all those measurements.

You can quickly determine apparel measurements with these simple steps and an attentive approach!

What is Grading

Grading apparel measurements is the process of making multiple versions of a pattern – from single sizes to many different sizes of finished garments. It involves modifying the original pattern according to an established sizing chart that considers body measurements and proportions, then meticulously drafting these changes precisely for each size.

This practice has been used by professional sewers for years, but with modern technology, at-home sewers can take advantage of this technique too! Most CAD software applications – think Adobe Illustrator or the Brother’s Design Software Pro Package – offer tools that make grading garment measurements more intuitive. These applications come with pre-drafted sizing charts so all changes are done automatically while allowing users to adjust their preferences based on the design they want.

However, it’s essential to remember that grading correctly requires knowledge of user measurements and how much “ease” or extra room you want to be built into the pattern pieces. Expanding our creativity beyond the scope of what an application offer is only sometimes feasible or desirable; when we know exactly what we need for our design, manual alterations on the pattern draft may be necessary.

At the end of it all, just remember: there’s no one-size-fits-all approach when it comes to garment construction and sizing! Grading can help us extend our patterns to fit people across all shapes, sizes, and abilities.

Why Measurements Matter In Retail

Apparel measurements are a vital component of the retail process. From creating customized garments to ensuring a proper fit for customers, this data is essential for companies that deal in apparel.

The customer gets a good fit.

- At first blush, you may wonder why apparel measurements are so important – after all, aren’t clothes designed to be ‘one size fits all?’ Not necessarily! Even when apparel does not require customization, like standard t-shirts and trousers, accurate garment sizing is still necessary to ensure the customer gets a good fit. Sizing charts are helpful but cannot substitute for accurate measurements taken from the actual piece of clothing.

- Plus, if you’re dealing with custom orders, then accuracy and precision become even more critical; sizes need to fit precisely, or else the customer could be happier. For example, an ill-fitting bridal gown can ruin a bride’s special day – it’s that serious!

Technical

- Another reason why apparel measurement matters in retail are technical. Pattern makers use sizing information to build their patterns on a body form that accurately represents their target customer base, and designers must fully understand garment measurements before they start designing garments.

- This ensures that garments would not only look great on a hanger but also look great when worn by potential customers – after all, fashion isn’t just about being seen but being seen looking fabulous! In this case, accurate measurements help create quality products that customers love and look fabulous simultaneously.

Monitor consumer trends

- Moreover, having both qualitative and quantitative data on one platform helps brands effectively monitor consumer trends related to product fit preferences, designs, or future design selection criteria based on some prior assumptions made based on data collected over time.

- By adding these dimensions together brands gain access to valuable insights while better understanding their customer’s needs; they know what styles work best with specific body shapes or what needs tweaking in order to enhance awesomeness levels to industrial proportions!

As you can see, apparel measurement is essential for several critical aspects of retailing, from sizing accuracy and product performance evaluations to staying ahead of consumer trends. Companies need tools that provide them quick, actionable analytics and ensure their garments are sized correctly for their target audience. Ultimately embracing measured-based decision-making within business operations should lead retailers toward success and help them make sure their customers leave satisfied every time.

Numeric and Alpha Sizing, Which Works Best?

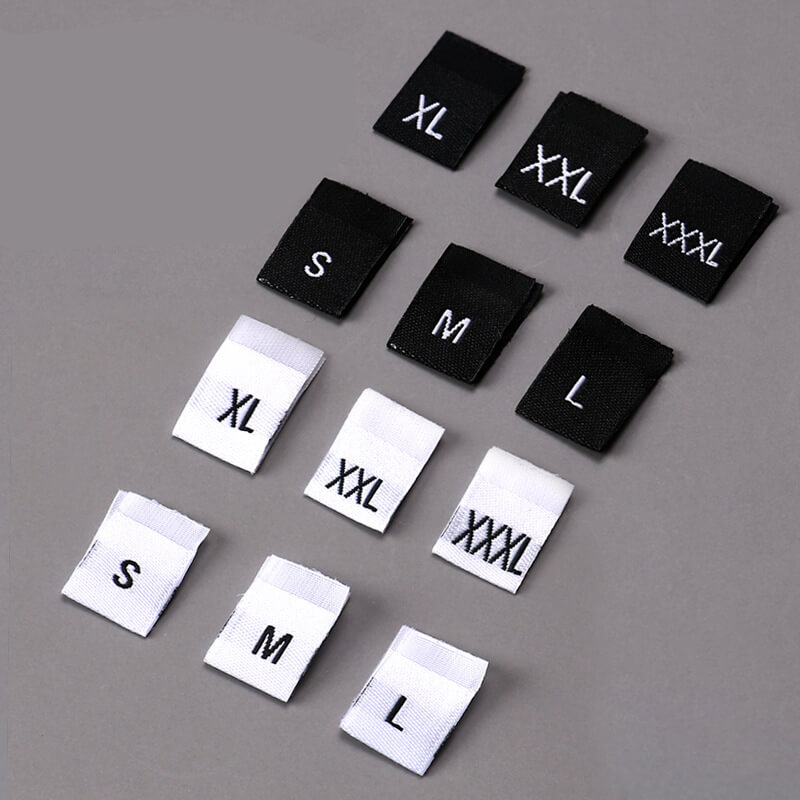

Numeric sizing

- Numeric sizing is the traditional method that defines sizes according to a uniform amount of fabric and body measurements, such as Small (S), Medium (M), Large (L), and Extra Large (XL). This system allows people to quickly identify their size without knowing their specific measurements.

- The downside of numeric sizing is that the numbers sometimes need to accurately reflect the actual clothing size; for example, an XL t-shirt from one brand could be much larger than an extra large from another.

Alpha sizing

- Alpha sizing, on the other hand, works differently in that it categorizes garment sizes according to personal body types – petite (PP or P), plus-sized (PL or PXL), or tall (MT or LT). This type of sizing makes it easier for people to find clothing items tailored to their body shape and lengths that can be adjusted depending on whether they are short or tall.

- The downside of alpha sizing is that it may only work for some occasions since there aren’t enough sizes available to fit everyone; something like a formal dress may not fit properly with this type of sizing. Ultimately, which system works best depends on what kind of clothing you’re looking for; if you want something casual and easy then numeric sizing might be suitable, while alpha styling could be better suited to more formal attire.

However, if you’re in doubt, try them out until you find something that fits your needs perfectly!

Wrapping up

No matter which size system you prefer, the key to successful apparel measurements is consistency. It’s essential to measure garments accurately and consistently to create a product that fits customers well and ultimately looks great.

With over a decade of experience in custom clothing production, Lezhou Garment is the perfect partner for you to ensure that your garments are sized accurately and crafted with precision. Reach out to us today and discover how our unparalleled knowledge of apparel measurements can benefit your business!