You’ve got some awesome designs and you’re ready to bring them to life, but you’re not sure which printing method to go for – sublimation or screen printing and each method comes with its own unique printing process and fulfillment techniques.

These two techniques are widely used to create awesome prints on your clothes and accessories. Both have their pros and cons! Let’s explore together and find out which one is the perfect fit for your style!

Are you stuck between the sublimation and screen printing techniques? Feeling confused about which one to choose for your designs, brand, or business? Keep reading and let’s get your questions answered!

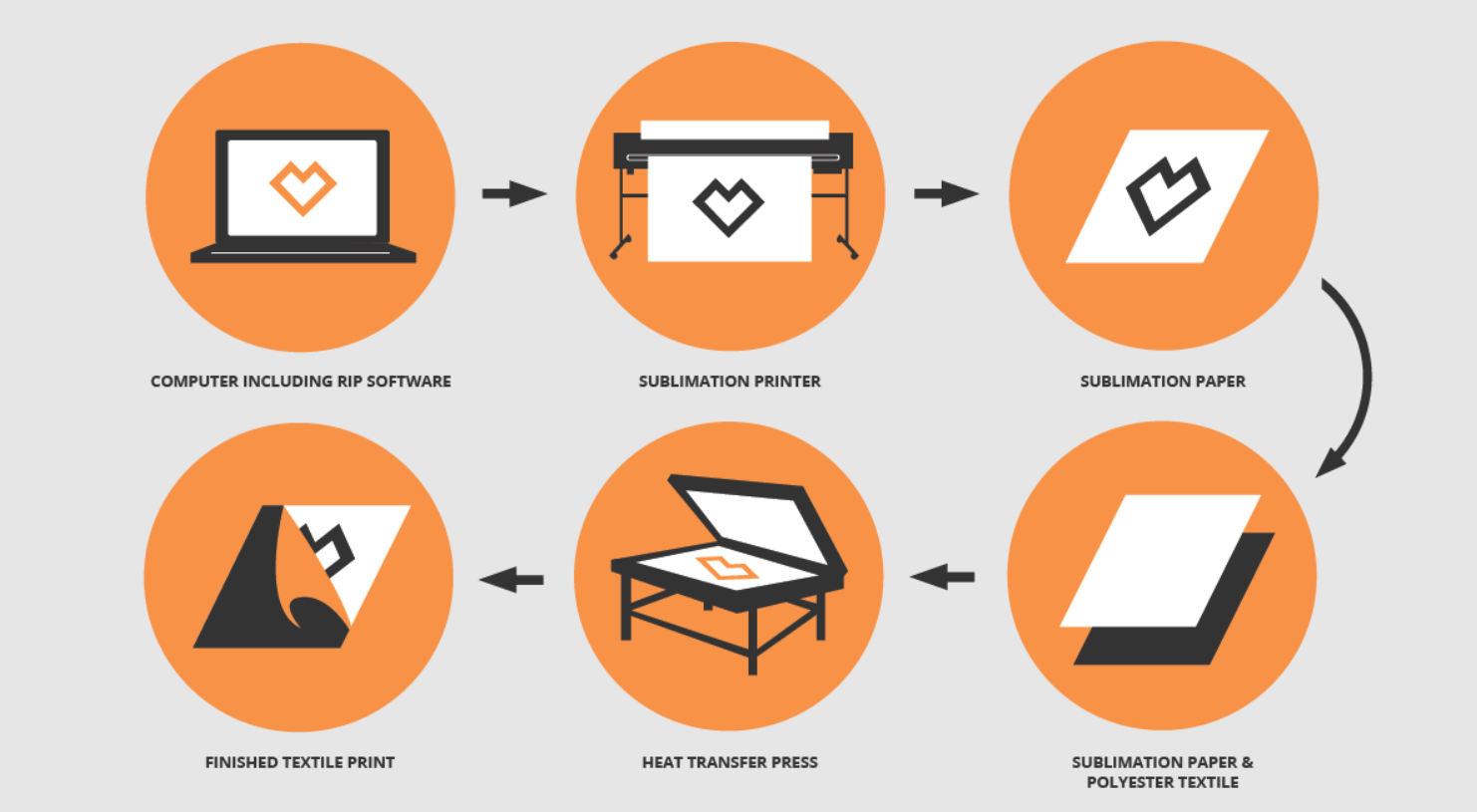

Sublimation printing: what it is and how it works

Sublimation, or heat transfer printing is a really cool technique where a design is infused into fabric using heat and ink. This method is popular for creating all-over print products in the print-on-demand industry. With sublimation, you can print on fabric from seam to seam.

Sublimation printing is a neat but pretty lengthy process, that is totally worth it. First, the design is printed on a special transfer paper. Next the transfer paper is carefully fed into a heat press machine along with the fabric. The high heat causes the ink from the paper to actually fuses with the fibers of the fabric. This results in a super durable and high-quality print that won’t fade or peel.

To get the best results with sublimation, it’s recommended to print on light-colored polyester, polyester blends, or polymer-coated fabrics. That’s because the ink really bonds with synthetic fibers, making for a vibrant and long-lasting print. In fact, the more polyester there is, the better the printing result will be! Sublimation is also used for printing on all sorts of home and living items. Think cozy blankets, fun mugs, stylish laptop sleeves, and even gaming mouse pads!

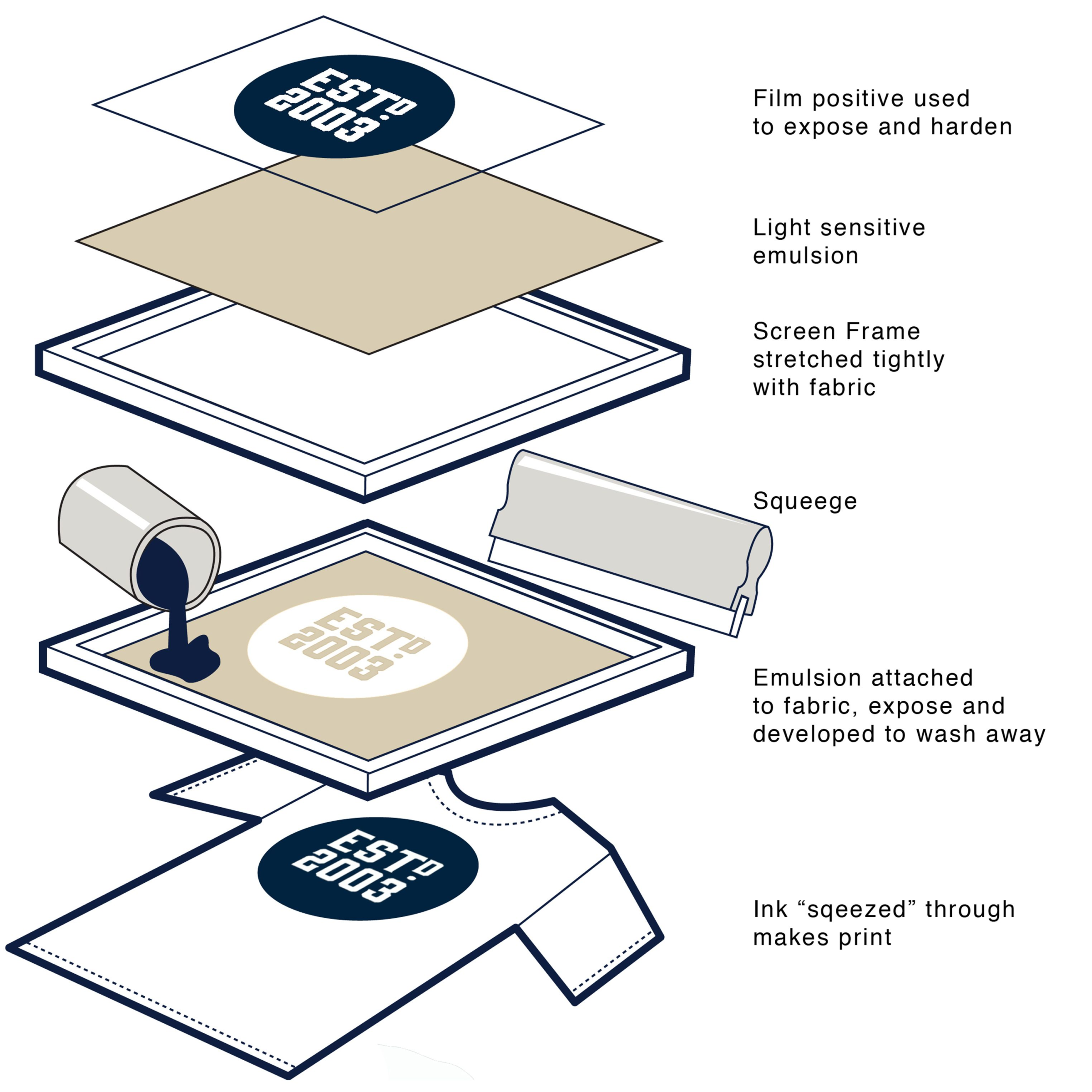

Screen printing: what it is and how it works

Sublimation printing and traditional screen printing, also known as silk screening, are quite different from each other. Sublimation is almost completely automated, but screen printing is largely a hands-on, manual process

If you opt for screen printing to bring your designs to life, you’ll need a special screen made for each element of your design? It’s a bit of a process, thus simpler designs with one or just a few colors tend to work best with this method, since each color is applied layer by layer.

The number of colors in your design can affect the amount of ink used during the printing process. The more colors you use; the more ink you’ll need to bring your design to life. A heavy layer of ink can actually create some cool textures on your garment. That’s because the ink tends to sit on top of the fabric rather than soaking in, resulting in a unique look and feel.

Sublimation vs. screen printing: what are the differences

Let’s dive into each printing technique in detail! This way, you’ll have a better understanding of which one will work best for your brand.

Print quality and durability

Sublimation print quality is outstanding. You can print fine lines and details in multiple colors that will be vibrant and sharp. Since the color is embedded into fabric fibers, it doesn’t wash out and it doesn’t crack or peel. Sublimation print is durable and very long-lasting. (even wash 50 times, colors still look new)

Screen printing also provides fantastic print quality. The colors are just as vibrant and sharp. However, screen printing doesn’t support very colorful designs like photos. If your designs contain just one or a few colors, screen printing can still be your go-to technique. Keep in mind that the ink doesn’t sink into the fabric as it does with sublimation. The more colors you print on the garment, the thicker the print will be.

Since the ink sits on top of the garment, screen printing can be less durable over time than sublimation printing. After many washes, the ink may crack and peel, and the colors can fade.

Print complexity

Sublimation printing supports designs of different complexity. You can print detailed pattern designs, gradients, colorful artwork, or digital photos.

Screen prints, on the other hand, are better for bold designs that contain one or a few colors. If you want to print artwork with more than one color, it should be simple. And remember that gradients are tricky. For example, if your design contains gradients, it may not come out exactly as you imagined it because they’re hard to print.

Number of colors

When it comes to colors, sublimation supports designs and gradients with multiple colors. Since sublimation is usually performed on white fabric, all whites in your design may be blank spaces on the fabric.

As for screen printing, as we’ve discussed, designs with one or a few colors work best. Each color has to be printed separately, which takes more time to print the garment. But screen printing can be done on different fabric colors, so you can use that to your advantage.

Special effects

Silk screening will be your only option if you want to add some pizzazz to your designs. For example, you can add glitter to your artwork or other types of inks for different effects. To create interesting textures or eye-catching designs, you can use specialty inks like gold or silver. Some inks produce a cracked or cork texture, or a leather effect.

Sublimation uses four primary colors (known as CMYK or cyan, magenta, yellow, and black) to print all designs. Unfortunately, sublimation printing doesn’t support specialty inks and other extras like glitter, so screen printing would be the better option in that case.

Fabrics and materials

Sublimation is most suitable for printing on white or very light-color polyester, polyester blends, or polymer-coated fabrics. 100%polyester fabric is the best fabric to do sublimation printing.

Screen printing is more suited for printing on cotton and cotton blends because the ink adheres better to such fabric fibers.

Eco-friendliness

If you’re looking for an eco-friendly fulfillment method, sublimation is a good choice. Sublimated products that are created on demand eliminate overproduction. Also, the sublimation ink is non-toxic and eco-friendly, and sublimation doesn’t require a lot of water compared to other dye transfer techniques.

Alternatively, when you choose to screen print products for your brand, you’ll most likely have to order in bulk to get the best price per item. This may result in leftover stock and product waste if your items don’t sell. What’s more, plastisol inks that are most commonly used in screen printing are toxic and not biodegradable. However, screen printing does support water-based inks that are more eco-friendly but you’ll have to do your research—not all suppliers use these inks.

Quantity

When it comes to the number of items you can print using sublimation, it’s perfect for both small and large orders. That’s why sublimation is one of the most popular methods among dropshipping companies as it’s easy to use this printing technique for as many or as few items as you need.

However, screen printing is more suited for bulk orders. That’s because each shirt is printed manually using stencils made specifically for your design. So you want to make a larger order (at least 100 pieces) as the price per t-shirt or other garments will be better in bulk.

What’s the difference between sublimation and screen print?

The main difference between sublimation and screen printing is that sublimation uses heat to embed ink into the fabric while screen printing is done by using a woven screen and squeegee to press ink onto the fabric. Sublimation is best for polyester fabrics and screen printing is best for cotton.

Can you sublimate on dark colors?

Sublimation is usually done on light-colored fabric—that’s the main choice for heat transfer printing. With the right methods, it’s possible to sublimate on dark colors but the process is lengthy and it may not achieve the desired outcome. First, a white base has to be sublimated on the dark fabric, and only then the design can be sublimated on top of it. But I don’t recommend doing sublimation printing on dar colors at all. Printing on white fabric will be the best choice.

Sublimation or screen printing – pros and cons

Sublimation

Advantages of Sublimation

- Sublimation Printing helps print everything all together in one piece without paying extra for the different designs or colors.

- The clothing won’t peel, fade, or chip as the ink becomes a part of the fabric. That makes the garment more durable, cleaner, and lighter.

- While using sublimation, one can use as many colors and designs as wanted. There is no limit to the number of colors or the type of patterns. Also, the cost remains unchanged whether producing ten units or a hundred.

- Without paying for the setup costs again, one can print the same design or logo again on another garment.

- Sublimation Printing is a cleaner and better printing technique as it allows for a lesser mess, unlike Screen Printing.

Disadvantages of Sublimation Printing

- Sublimation Printing works best on light or white polyester fabrics and would fail to work on dark colors as it uses transparent inks.

- It works well only on polymer-coated or polyester surfaces. And not on fabrics that have less than two-thirds of polyester. The more polyester, the better the printing effect.

Silk screen printing

Benefits of Screen Printing

- An individual willing to set up Screen Printing can select from a diverse range of inks that will help you produce special effects. With the correct type of ink, one can create foil or 3D designs.

- Screen Printing can be done on nearly any textile material as long as it has a flat surface.

- Screen Printing is cost-effective for high volumes of fabrics of the same design.

- There are lesser details. Hence, making Screen Printing an excellent selection for graphics, names, or logos. However, it may not be suitable for intricate designs or photography.

Drawbacks of Screen Printing

- If an individual wants to use multiple colors, they will have to add each color separately. Therefore, increasing the production time and adding up to costs.

- When doing Screen Printing, one can use a limited amount of colors. Thus, resulting in relatively simple designs.

- If you are making a single t-shirt, it may cost more, as screen printing is a lengthy process. Also, adding up to the costs along with consuming more time too.

- Screen Printing cannot add details to the designs. So, people who want to have technicalities prefer other printing methods.

- The design may fade, peel, or crack over time (after washing for more than 50 times), not making it a priority for people who want long-term prints.

Is sublimation printing better than screen printing?

Sublimation printing easily creates multi-color design prints and is highly durable because the dye becomes a part of the fabric. Also, it does not fade, crack, or peel with time and creates vibrant designs on flat fabric. However, it only works on polyester and looks best on white or light surfaces.

On the other hand, silk screening or screen printing creates a unique textured design. The design stays durable after some washes, yet it may crack eventually. It is economical to use screen printing when you have bulk orders, as its setup costs are relatively high. It would also work best with fewer colors.

Some last words

The difference between screen printing and sublimation is that both printing techniques have their benefits and drawbacks. However, it is important to remember that which printing method to use is depending on the fabric and your designs. We not only use the two techniques described in the article above but also use several other printing methods for different printing purposes.

If you still don’t know which printing to do for your design, talk to us today!