If you are looking for a printing process that can produce high-quality results, silk screening may be ideal.

This process can create prints on various materials, including fabric, paper, and plastic.

This blog post will discuss what SilkScreen printing is, its types, and how it works!

What is SilkScreen Printing?

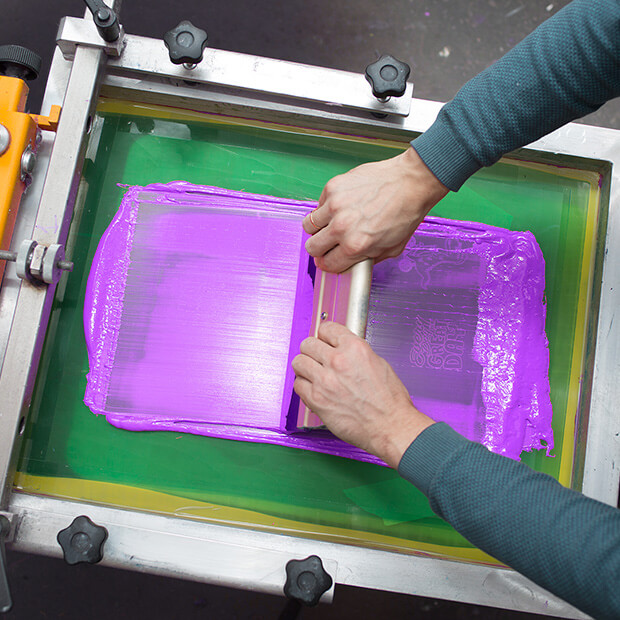

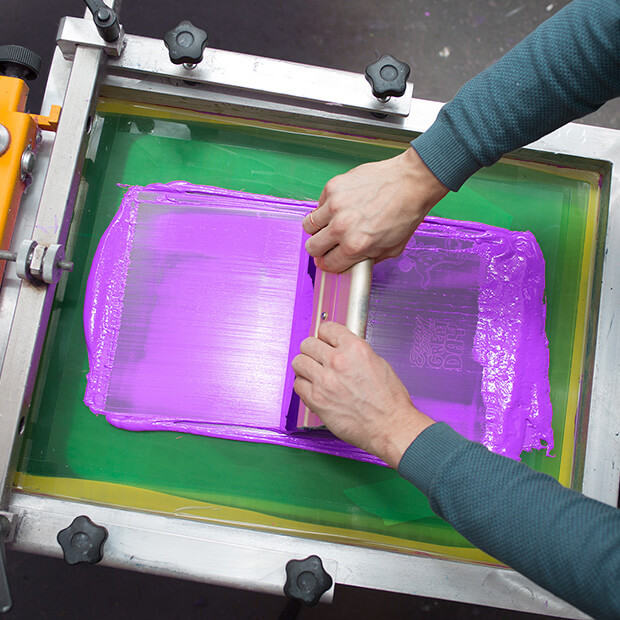

In Silkscreen printing, a mesh transfers ink onto a substrate, such as paper, fabric, or plastic. Squeegee is moved across the screen. It forces ink through the mesh, and the image is then transferred to the substrate. It can also be used for fine art prints.

The practice was introduced to Western Europe by Asia in the late 18th century, although it was not widely utilized until silk mesh became more readily available. Pop Art pioneers like Andy Warhol and James Francis Gill elevated silkscreens to the forefront of the contemporary art form in the twentieth century.

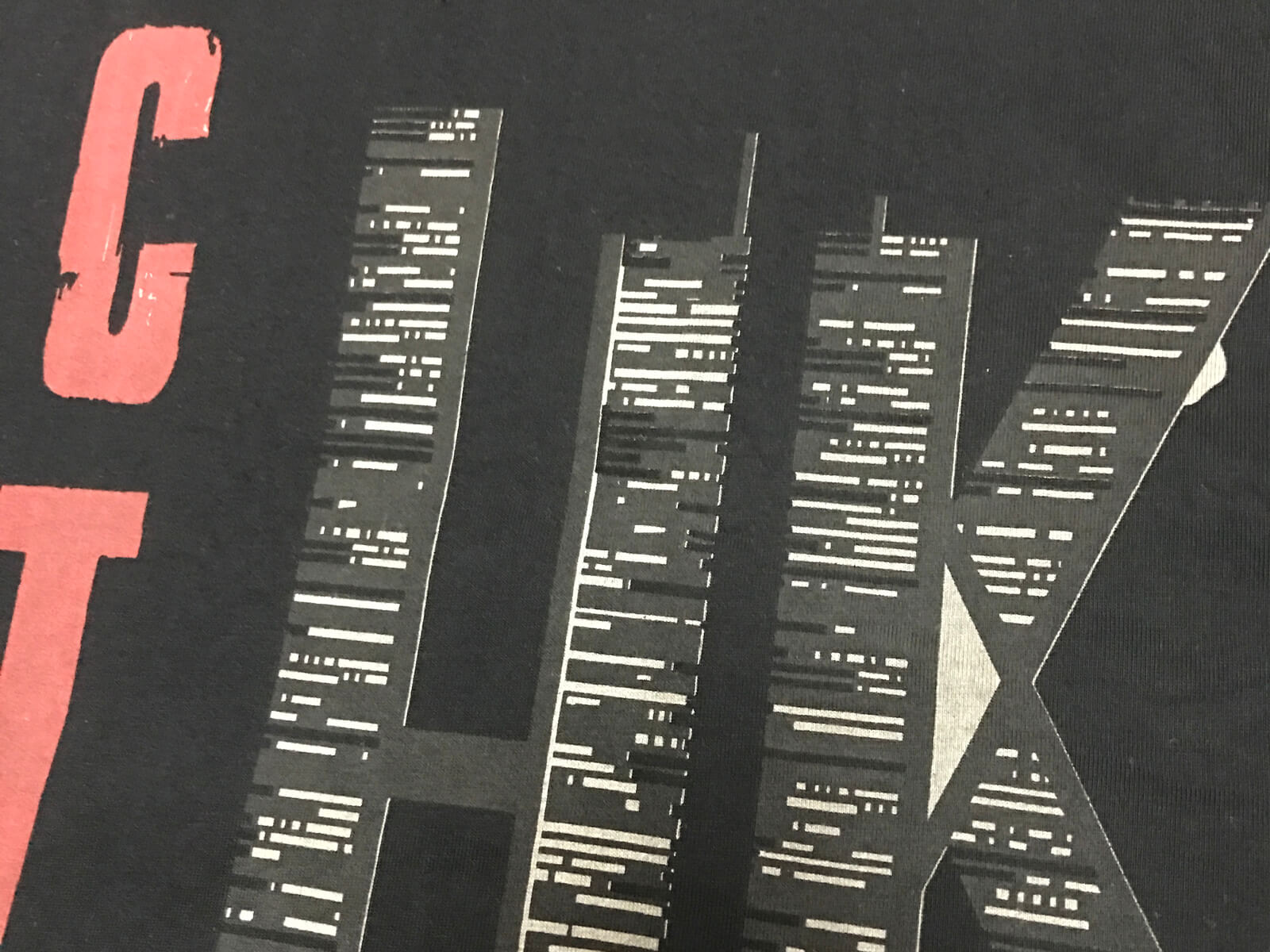

Nowadays, US-made use this technique to produce thousands of posters for a federal art project. Screen printing became very popular with band merchandise during the 1970s and 1980s.

How Does SilkScreen Printing Work?

A silk screen printer works by pulling ink across a printing frame. Then the ink is injected into the fabric or material being printed. There are two types of screen printing: machine screen printing and artificial screen printing.

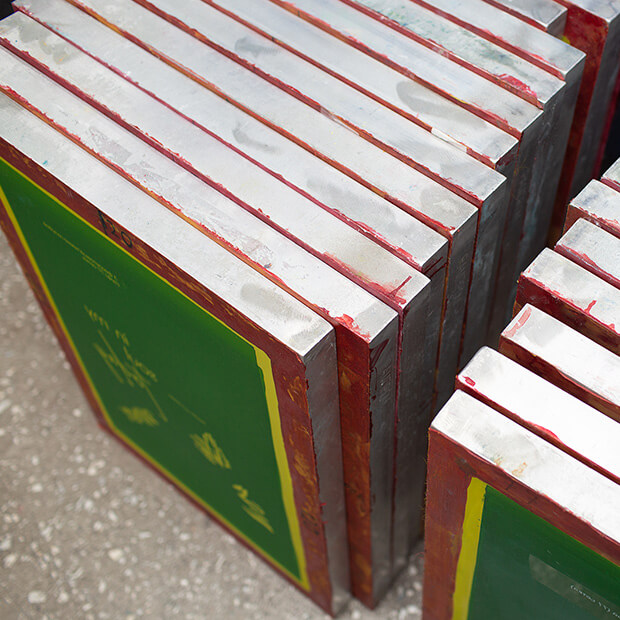

First of all, you’ll need to prepare the film and then is the screen. It is coated with a photosensitive emulsion exposed to light and consists of a fine mesh fabric that is tightly stretched and attached to a metal or wooden frame.

Areas not exposed to light will harden, while those exposed to sunlight will remain soluble.

The screen is then put on a squeegee, and ink is applied to the screen. The squeegee forces the ink through the open mesh onto the fabric or material being printed.

The photosensitive emulsion washes away from the areas that were not exposed to light, leaving a stencil on the fabric or material being printed.

9 Different Types of Silk Screen Printing:

There are many different types of silk screen printing, and each one has its advantages and disadvantages.

Here are the most popular types of SlikScreen Printing:

Water-based screen printing:

Water-based screen printing is a type of printing that uses water as the vehicle to transfer dye to a substrate, such as paper or textile. The process entails forcing a fine mesh screen down onto the surface of the fabric or paper with even pressure. Ink is then forced through the mesh openings by a squeegee onto the desired area of the substrate.

One of the main benefits of water-based screen printing is that it’s environmentally friendly and breathable. The ink doesn’t contain any harmful chemicals, and it can be easily cleaned up with just soap and water. In addition, since there’s no solvent used, there’s no hazardous waste to dispose of.

After washing 5-10 times, the water-based printing will fade a bit and bring a used look to the graphic.

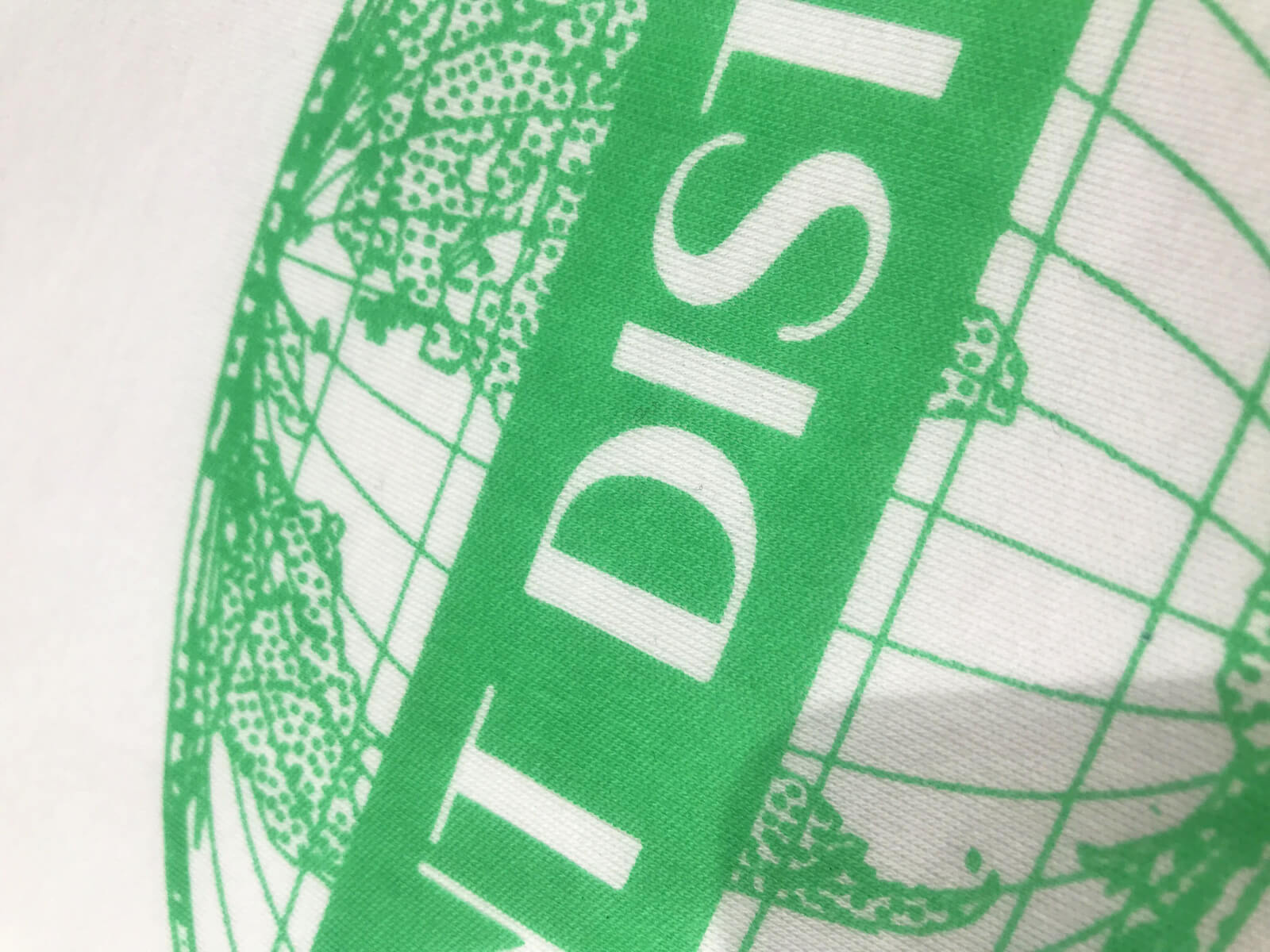

Plastisol-based screen printing:

Plastisol-based screen printing is a printing process that uses a particular type of ink called plastisol. Plastisol inks are oil-based, which means they stay liquid until heat is applied, at which point they become solid.

This makes them perfect for screen printing because the image can be printed onto fabric without the ink running or bleeding.

The downside to using plastisol inks is that they can be not sustainable and not breathable. They also have some odour, making them unpleasant to use. However, plastisol inks are durable and long-lasting, and they provide a high level of detail and clarity.

Even after washing more than 20-30 times, the plastisol-based printing still looks new and it can be washed more than 50 times. No cracks, without wash-off problems.

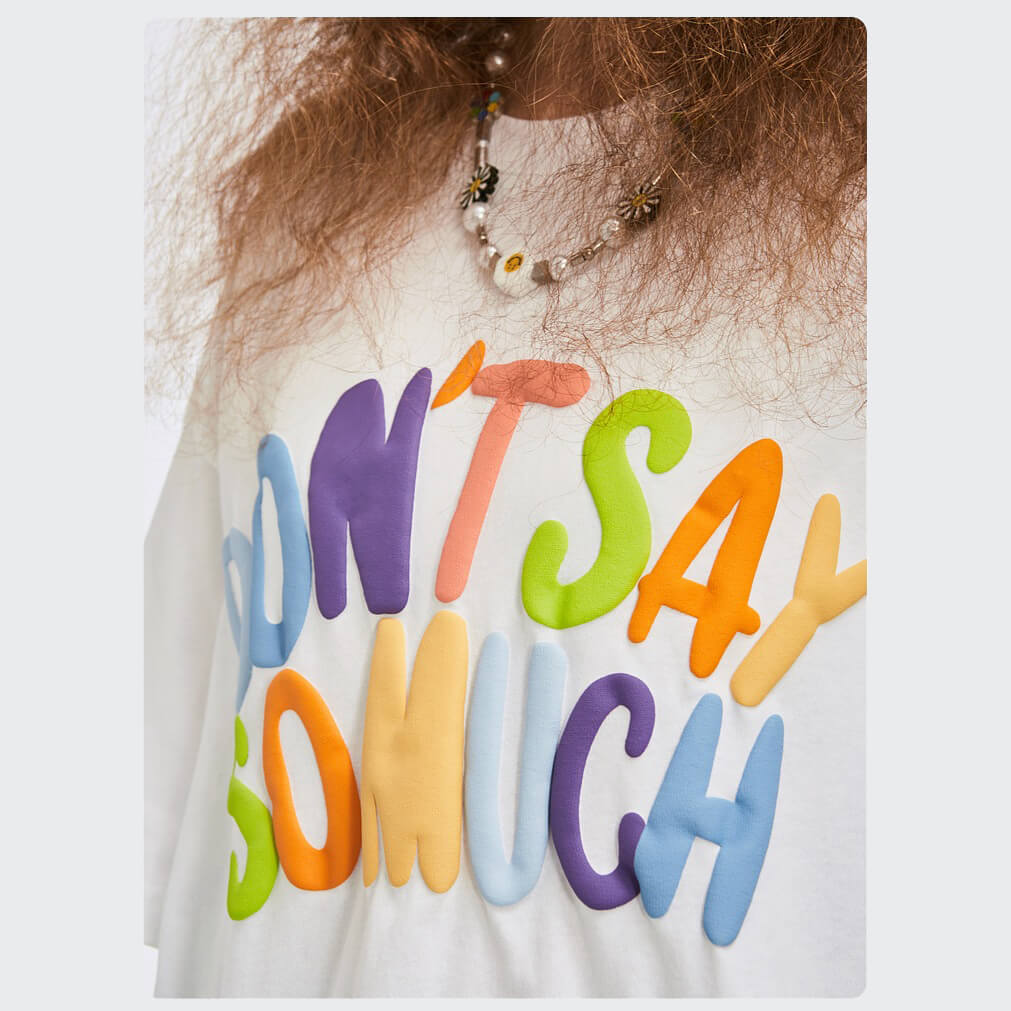

Puff printing:

Puff ink is a screen printing ink that is used to create a 3D effect on garments. It is also known as raised ink or 3D ink. Puff ink is thicker than regular screen printing inks and contains a chemical agent that causes it to expand when it is cured with heat. This expansion creates a raised, textured print on the garment.

Generally, puff inks are used for printing on t-shirts, sweatshirts, and other types of apparel. They can be used to create a variety of different effects, from subtle to dramatic. Puff inks are available in a wide range of colors, including metallic and fluorescent shades.

Puff printing is a great way to add dimension and interest to your garments. It is also a good choice for prints that will be seen from a distance, such as team logos or event graphics. Puff printing is more expensive than regular screen printing, but the results are definitely worth it!

3D printing (high-density printing):

High-density printing is achieved by stacking layer upon layer of ink to raise the print above the fabric by up to 3 mm (1/8 inch).

This type of printing is often used for logos or other designs that need to be highly visible.

However, it can be more expensive than other types of printing, and the raised design can be susceptible to damage.

Small Tips: What’s the Difference Between Puff Printing & 3d Printing?

The main difference between puff printing and 3D printing is the thickness of the raised design. Puff printing creates a design that is only slightly raised, while 3D printing creates a design that is much thicker. 3D printing is also more expensive than puff printing.

Metallic screen printing:

Metallic screen printing is a popular technique that provides a lustrous, matte finish to logos and images on fabrics, paper, and solid materials.

Of all the specialty screen printing methods today, metallic ink printing and foil printing are among the most requested designs. Metallic screen printing uses a special kind of ink that contains metallic flakes.

The ink is applied to the screen just like regular ink, but when it dries, the flakes reflect light and create a shiny, metallic appearance. This type of printing is often used for creating elegant logos and graphics for upscale events or products.

However, it should be noted that metallic inks can be more difficult to work with than regular inks, so it is important to choose a qualified printer who has experience with this type of printing.

Reflective Screen Printing:

Reflective printing inks are a specialized type of ink used for screen printing. As the name suggests, these inks are designed to reflect light, rather than absorb it. This makes them ideal for use on dark surfaces or in low-light conditions.

Reflective inks are available in a variety of colors, including white, silver, and red. They are also relatively easy to print with and have good adhesion and resistance to bending.

However, it is important to note that reflective inks do not glow in the dark on their own. Instead, they rely on another light source to reflect light back to the viewer.

Flock printing:

Flock printing is a printing technique used to create a sense of depth and texture. It involves using multiple colors of small particles (flocks) to give the appearance of fibers or feathers.

The printer deposits one color of flock onto the substrate and then uses a second color to overlay it in a slightly different direction.

This gives the impression of movement and depth. Flock printing can be used on various materials, including paper, fabric, and even wood.

Discharge printing:

Discharge printing is a printing technique that removes the dye from a previously printed garment to create a unique underpainting effect. The result is a lighter-colored print on top of a darker-colored base garment.

The discharge process starts with the application of white ink to the fabric. Next, the areas where the image will be printed are covered with a photosensitive emulsion. The emulsion is then exposed to ultraviolet light, which causes it to harden and insolubilize.

Finally, the fabric is treated with sodium hydroxide (or another alkali), which dissolves the unhardened emulsion and removes the image’s colorant.

Discharge is the similar as water-based printing, soft and breathable, and it is longer-lasting than water-based printing.

CMKY Screen Printing::

CMKY is an abbreviation for Cyan, Magenta, Yellow, and Black. It is one of several printing methods used to produce a full-color image. Other color printing methods include the four-color process (CMYK) and spot color.

With CMKY screening, each dot is printed in one of the four colors, with black being the most common. This technique produces a higher quality image than the four-color process because it uses dots rather than screens to create the image.

Additionally, CMKY screening allows for more precise control over the image’s final appearance.

Advantages of Silk Screen Printing:

There are many advantages to using the silk screen printing method.

Here are some:

- You can print on various materials: With silkscreen printing, you can print on paper, cardstock, poster board, fabric, wood, metal, glass, and more. This makes it a versatile printing method for a wide variety of projects.

- The ink is laid down in a smooth layer: The ink is forced through a stencil onto the material below, so the final product has a smooth, even layer of ink. This is in contrast to methods like block printing, where the ink is applied with a stamp or roller, which can result in an uneven finish.

- You can achieve high-quality prints: With the right tools and materials, you can achieve high-quality prints with silkscreen printing. The key is to use a high-quality screen mesh, stencil, and ink.

- Prints are durable and long-lasting: The ink is applied in a smooth, even layer, and prints made with silkscreen printing are durable and long-lasting. Even after washing 20times, it looks brand new.

- It’s an affordable printing method: Silkscreen printing is relatively cheap compared to other printing methods. This makes it perfect for small brands, businesses, and hobbyists.

- You can create detailed and intricate designs: You can create detailed and intricate designs with silkscreen printing. The stencils used in this printing method can be made with very fine details.

- Wide range of colours available: A wide range of colors is available for silk screen printing. This allows you to create prints that are truly unique and eye-catching.

These are just some of why silk screen printing is a popular choice for printed products.

Disadvantages of Silk Screen Printing:

There are also some disadvantages associated with silk screen printing, such as:

- It can be time-consuming: Silk screen printing can be time-consuming, especially if you create a large print run. Around 3-4 days for screen printing.

- It can be expensive: Silk screen printing can also be a costly printing method, particularly if you need to use multiple screens for your design. For example, 5x5cm one-colored screen printing logo cost only US$0.43. When the same size logo mix 6 different colors, its price will be high to US$2.

- It can be challenging to print complex designs: It can be challenging to print them using a silkscreen if you have an intricate design. Each color in your design will require a screen, which can be costly and time-consuming. Also, for some very fine lines, screen printing may not be able to print it accurately.

Despite these disadvantages, silk screen printing remains a popular choice for many businesses and individuals.

What Will Affect the Price of Screen Printing?

There are a lot of things that affect the price of screen printing.

Size of your printing:

One of the things that affect the price of screen printing is the size of your printing. If you have many areas that need to be covered, it will cost more. The larger the project, the more ink, and screens you’ll need, and the longer it will take to complete.

For example:

- 5*5cm one-colored screen printing logo costs US$0.43

- 30*30cm one-colored screen printing logo costs US$1

How many colors of your printing design:

The number of colors you’re using is another factor that affects the price. The more colors you need, the more set-up time it will take, and the more screens or prints we’ll need to produce your project.

Every additional color requires a new film positive. Each film positive requires a new screen. Both film and screens cost money. Also, for more colors, our printing workers need to spend more time. As they need to print 10 times if the graphic includes 10 different colors!

So silk screen printing cost is not only based on the graphic size but also on how many colors we print.

For example:

- 10*10cm one-colored logo, cost US$0.65

- 10*10CM 10-colored logo, cost US$4.75-6

Types of screen printing to choose for your printing:

This is another factor that will affect your price. For example, if you want a very fine print, we’ll need to use a higher mesh screen, which costs more money. The number of screens or prints you’ll need will also affect the price.

Can Screen Printing Apply to Any Fabric?

Yes, screen printing can be applied to any fabric. The process begins with a design created on a computer and then converted into a digital file. That file is then sent to a printer, which prints it onto a unique mesh screen.

Then the screen is placed over the fabric, and ink is forced through the mesh openings with a squeegee. The fabric is then put through a screen printing press to cure the printing ink and create a permanent print. Screen print can be used on light or dark fabrics and even on non-traditional surfaces like metal or wooden frames.

Wrapping Up:

That’s a quick overview of silk screening and how screen-printer works.

Do you have any more questions or would like to learn more about the screen printing process, screen printing equipment, or commercial screen printing? Please do not hesitate to contact us.

Lezhou garment, with over 18 years experience in custom clothing manufacturing, we would be happy to walk you through every step of the silk-screening process and answer any questions you may have.

Thanks for reading!