DTG printing is a relatively new technology that has taken the world by storm. Direct-to-garment printing allows you to print your designs onto T-shirts, hoodies, and other clothing items.

This process is much more affordable than traditional screen printing, allowing you to be highly creative with your designs.

In this article, we’ll take you through everything you need to know about DTG printing, from the types of fabrics it can use to the different printhead technologies available.

So whether you’re just starting in the DTG market or are looking for ways to improve your printing process, read on for all the information you need.

What is DTG Printing?

Direct to garment (DTG) printing is a process of printing on textiles using inkjet technology, initially developed for the industrial textile market.

DTG printers typically have larger print heads that push ink onto garments, much like an office inkjet printer.

The difference between traditional methods like screen-printing and DTG printing is that the garment does not need to go through any further manufacturing processes once the design has been printed.

This means DTG printing is much more versatile for small runs and one-offs as there is no need for setting up screens or making test prints.

DTG machine can be used to print custom t-shirts or other fabrics.

How Does it Work?

Direct to garment (DTG) printing is a textile printing process using Inkjet technology, usually with a specialized commercial Inkjet printer.

Designers can create customized designs and graphics, which can be printed on-demand, making DTG an excellent option for small businesses or those interested in customizing their garments.

Orders can be filled quickly and efficiently without the need for setup fees or large minimum order quantities.

Advantages of DTG Printing:

There are several advantages to DTG printing, which is why it has become such a popular method for printing garments.

DTG printing is:

- More delicate and detailed:

DTG printing is famed for creating amazing delicate designs. No matter whether your design is a photo or detailed graphics, DTG can always result in the best details. Other printing methods, such as screen printing, aren’t the most suitable to enhance complicated and finicky designs.DTG makes your designs pop and stands out from the crowd.

DTG printing

- Faster:

Once your design is created, it can be printed on-demand so that orders can be filled quickly and efficiently.

This is a significant advantage over screen printing, which typically has longer production times due to the need for setup and clean-up time between each print run.

- More versatile:

DTG printers can print on various fabrics, including cotton, polyester, and some blends. This makes DTG an excellent choice for printing on a variety of garments, from t-shirts to hoodies.

In addition, DTG prints can be created in full color, allowing you to be creative with your designs.

- More Breathable

DTG printing clothing have a natural feel, you can even see the fabric texture from the printing. DTG printing injects the ink into the fabric, you won’t see a raised graphic on the clothing. So, DTG printings are super breathable and soft to the touch.

Disadvantages of DTG Printing:

While DTG printing has many advantages, there are some disadvantages to consider as well.

DTG printing is:

- Not ideal for large orders:

If you want to print many shirts, DTG printing is not the most efficient option. Screen printing is a better choice for large orders as the setup time is much shorter, and the per-shirt price decreases with larger quantities.

- Less durable:

DTG prints are less durable than screen prints, making them more likely to fade or crack over time. If you want a garment that will last for years, other printing methods like screen printing are better.

- Sensitive to heat:

DTG prints are susceptible to heat, so it is essential to take care when washing and drying garments with DTG prints. We recommend washing in cold water and air drying to extend the life of your garment.

Now that you know all about DTG printing, you can decide if it is the proper method for your next project.

- Fabric limited

DTG printing must be applied on fabric without silicone oil or the graphic will be fade and peel off very soon.

How Much Does Direct-to-Garment Printing Cost?

Multiple things affect the price of DTG printing.

The cost of the garment, the number of colors in the design, and the print size all play a role in determining the price.

For example, a one-color print on a t-shirt will be less expensive than a four-color print on the same garment.

Similarly, a small print will cost less than a significant print.

The price of DTG printing also varies depending on the printer used.

Some printers are faster and more efficient, leading to lower prices.

To get an accurate estimate of the cost of your DTG project, it’s best to request a quote from a printer.

When requesting a quote, be sure to include the number of colors in your design, the print size, and the type of garment you’ll be printing on.

Factors that Affect Price of DTG Printing:

- Garment color: DTG printing on dark clothing will cost more than print on light color clothing because printing ink is more difficult to dye on dark fabrics. So we must use more ink and do more work for fixation colors.

- The number of colors: The number of colors in your design will also affect the price. DTG printers typically charge by the number of colors in a design, so a design with more colors will be more expensive to print.

- Print size: The size of your design will also affect the price. DTG printers typically charge by the square inch, so a more extensive design will be more expensive to print.

Now that you know all about the cost of DTG printing, you can decide if it is the proper method for your next project.

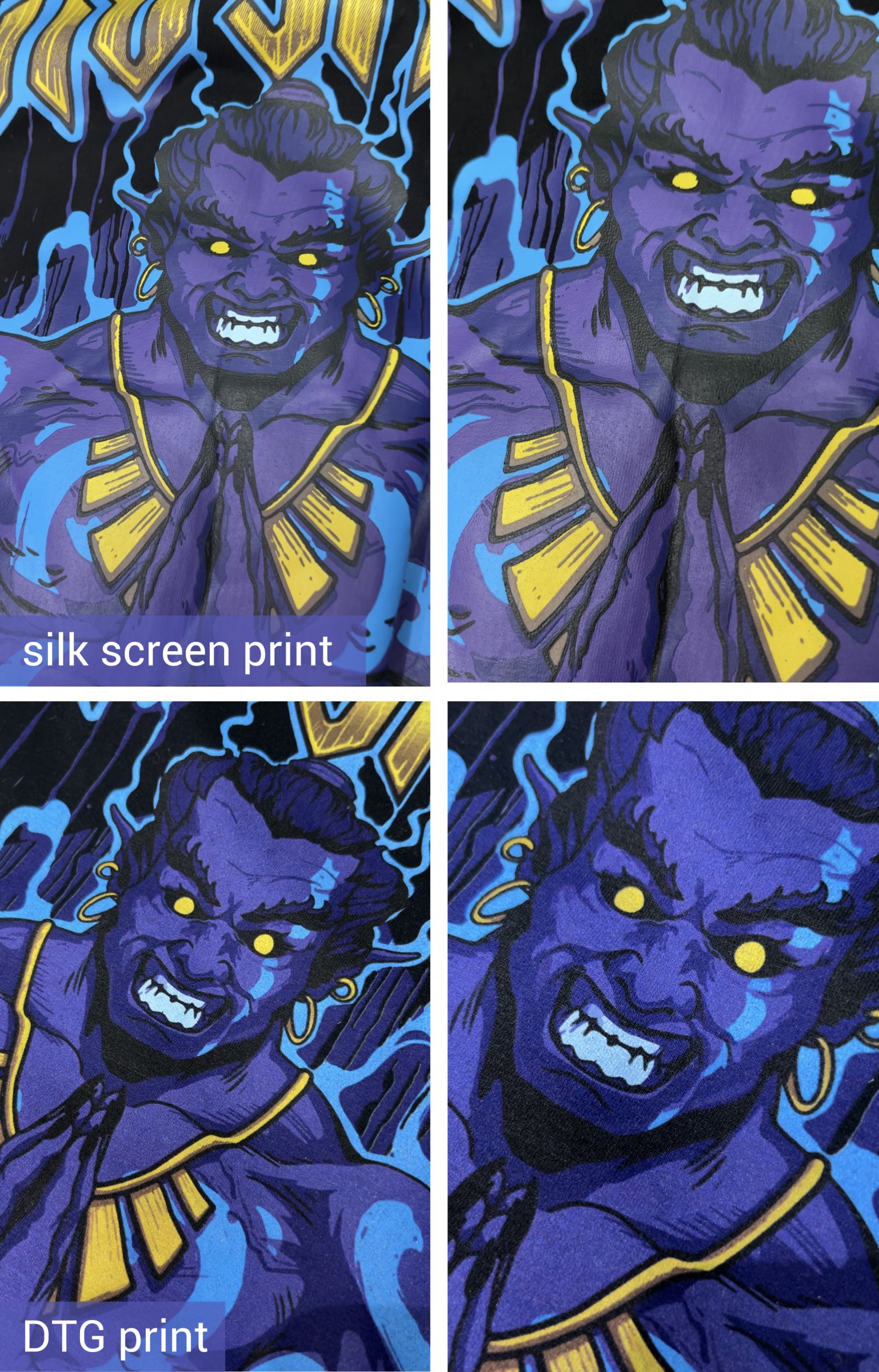

DTG Printing VS Silk Screen Printing

There are a few critical differences between DTG and screen printing.

DTG ink (direct to garment) printing generally has a shorter turnaround time than a screen print, and the print details is often higher with DTG printing.

However, DTG printing is typically more expensive than silk screen printing, and it isn’t well-suited for large runs of prints (i.e., more than 50 garments).

Silk Screen Printing is a centuries-old method of fabric printing that Pat Slaven of Rivolta Carmignani wrote: “requires no special skills other than the ability to operate a fairly simple press.”

In brief, a stencil or “screen” is created, usually out of nylon or polyester. The design is burned into the screen using a light-sensitive emulsion, and ink is pushed through the holes in the stencil onto the fabric.

This process can be repeated for each color in the design, which is why it’s well-suited for large runs of prints (it’s also why it has a longer turnaround time and is not as breathable as DTG printing).

Verdict: If you’re looking for a high-quality print with a shorter turnaround time, DTG printing is a good option. However, screen printing is the way to go if you’re looking for a more cost-effective option or need to print large quantities of shirts.

DTG Printing VS Sublimation Printing

DTG printing is a direct-to-garment method that uses inkjet technology to print images on fabric.

Compared with sublimation printing, the critical advantage of DTG printing is that it can be printed on cotton fabric, cotton polyester, or polyester fabric. As long as the fabric is without any silicon oil.

However, DTG printing’s color is not as vivid as sublimation printing and not that long-lasting either.

Sublimation printing is a digital printing method that uses heat to transfer dye onto fabric.

The advantage of sublimation over other methods like screen printing is that it doesn’t require any setup fees, and the colors are more vibrant than DTG printing. It is also more cost-effective and more breathable compared with DTG.

However, sublimation prints can only do on 100%polyester or at least 95%polyester, or the color will fade very soon. The more polyester in the fabric, the better the sublimation printing result.

Can DTG Printing Apply to Any Kind of Fabric?

Yes! DTG print can be used on any t-shirt or other fabric, from natural fibers like cotton and linen to synthetic fibers like polyester. But please make sure the fabric is without any silicon oil. The key is to use the right kind of ink and pretreatment solution for the specific fabric you’re working with.

Different fabrics require different pretreatment solutions for the ink to adhere properly. For example, polyester fabrics need to be pretreated with a solution that bonds the ink to the fabric. In contrast, natural fibers like cotton only need light pretreatment that helps the ink penetrate the fabric.

In general, DTG printing is an excellent option for any fabric. You can produce high-quality prints on any fabric with the right supplies and knowledge.

Conclusion:

DTG printing is becoming more and more popular.

If you are looking for a quality, breathable and delicate printing option, then DTG may be the right choice.

We hope our complete guide has answered all your questions and given you a better understanding of DTG printing and how it works.

If you have any additional questions or need help getting started with DTG printing, feel free to contact us anytime.

Lezhou Garment has over 18 years of experience in manufacturing custom clothes, would like to be your clothing manufacturer-partner in China!

Thank you for reading!