Are you a clothing manufacturer who’s just starting out or a brand in search of the perfect manufacturing strategy? Look no further! Our simple guide is here to help you kickstart your journey to success. We’ll help you determine the best approach to make sure your collection comes to life seamlessly. Let’s get started!

Different types of clothing factories

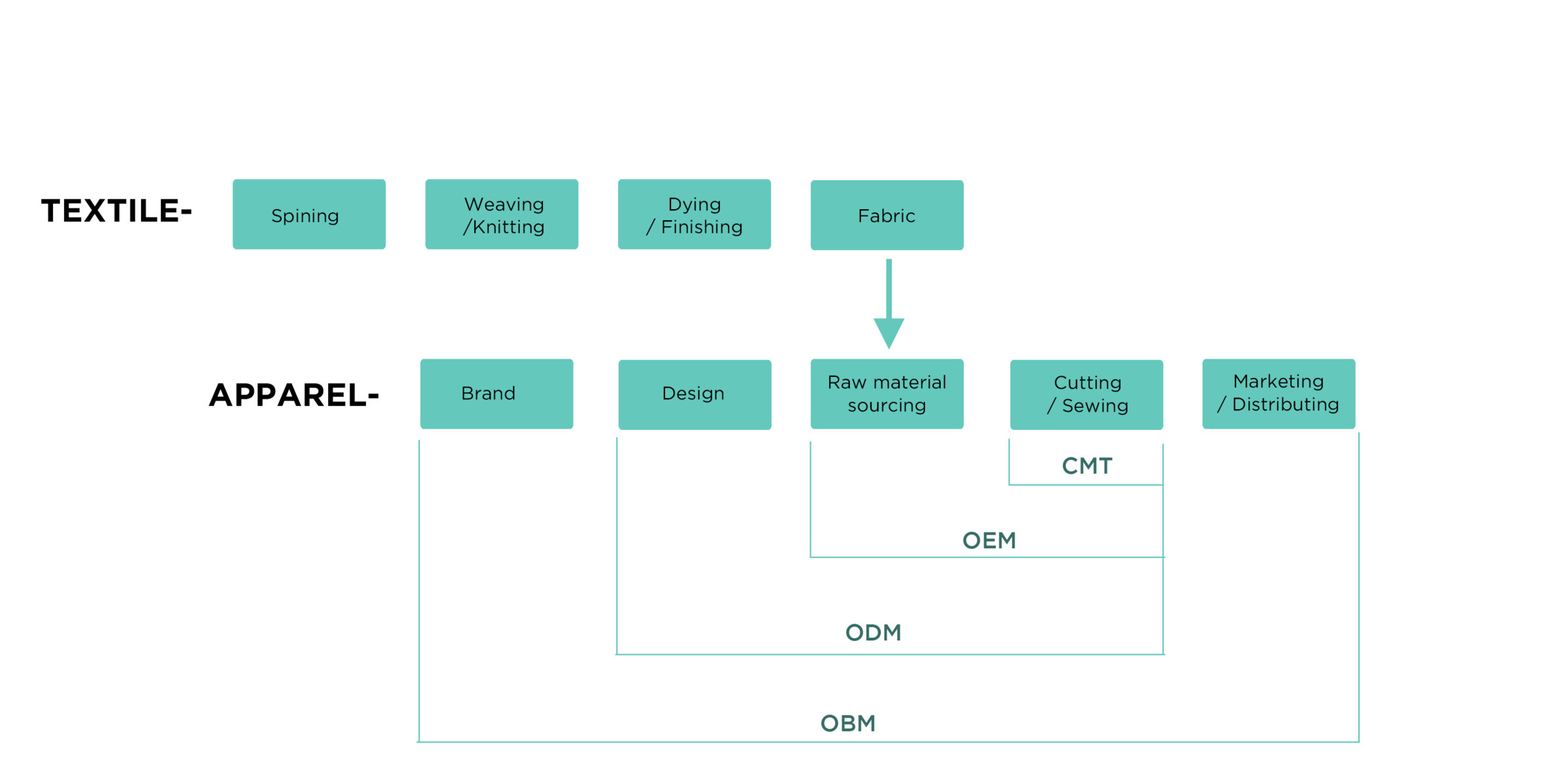

1. CMT (Cut, make, trim) clothing production

CMT (Cut, make, trim) is one of the four primary types. With CMT, you get a comprehensive service that covers everything from cutting and trimming to sewing your garment into a fully finished masterpiece. It’s an all-in-one package that can help bring your fashion ideas to life.

Looking to take advantage of this type of manufacturing for your clothing brand? To get started, make sure you have these essentials on hand:

- Tech Pack and Specs Sheets

- Fabrics and trims

- Patterns, constructing requirements and sewing guidance

Once the supplier receives all the necessary information, they jump right into the production process! First, they will cut the fabric according to your technical sketches and patterns. Then, sew each piece together to meet your construction requirements. They also adjust sizes to perfection using the Grading Sheet you provided. Finally, the supplier performs a thorough quality check to ensure that everything meets your expectations.

Here are some tips to keep in mind: CMT is an excellent choice for brands with experience in the production process and a factory-ready tech pack. However, if you’re a new brand just starting out, we recommend exploring the FPP (Full Production Package) that we’ll discuss below.

2. FPP (Full Production Package) clothing production

FPP or Full Production Package is a one-stop shop for all your clothing production needs. With FPP, you get a comprehensive service that covers every stage of the garment building process, from start to finish. It’s the perfect solution for brands looking for a hassle-free experience and top-quality results.

These stages include:

- Pattern making.

- Fabric and trim sourcing.

- Sample Making.

- Final garment production.

In a nutshell, FPP covers CMT and every other aspect of garment manufacturing.

Here’s how suppliers get the manufacturing process started at the factory:

- Consult with you to ensure they understand your vision.

- Use your initial sketches or mood boards to create detailed technical designs that will bring your ideas to life.

- help with fabric sourcing.

- Offer their expertise in current fashion trends, so you can stay ahead of the curve.

- Manufacture the final garment to the highest standards, so you can be proud to put your brand’s name on it.

Simply put, factories that offer FPP are your one-stop shop for all things product development! With FPP, you can count on the team to guide you through the entire process.

Here are some helpful tips: FPP is the perfect choice for your clothing production needs. With FPP, factories offer a comprehensive service that covers every stage of product development – everything from initial designs to fabric sourcing to constructing the final product.

| CMT | FPP |

| Cutting | Product development |

| Trimming | Pattern making |

| Sewing | Fabric sourcing |

| Cutting | |

| Trimming | |

| Sewing |

3. Original equipment manufacturer (OEM)

An OEM (Original Equipment Manufacturer) clothing factory that specializes in manufacturing clothing products based on your brand’s specifications and designs. These factories focus on bringing their client’s vision to life and typically don’t create or market our own products.

Working with an OEM clothing factory might be the perfect solution for your brand or retail business! OEM clothing factories often deliver high-quality products, while also meeting your production volume, quality standards, and delivery timelines.

4. Original design manufacturer (ODM)

ODM products are based on the design of the manufacturer and can be the result of their research and development work or a counterfeit product of another brand. But don’t worry – you can put your logo on ODM clothing and make it your own!

Besides, ODM companies produce only slightly changed versions from their original design, they can still be customized to meet your specific needs and requirements. This means that you can benefit from the convenience of having a product that is ready to go, while also having the flexibility to make it your own.

ODM companies usually have the expertise to produce products in bulk, perfect for businesses of all sizes. When it comes to ODM, there are two categories to consider: private label and white label.

Private-label products are those that are manufactured by one company and sold under another company’s brand, while white-label products are those that are manufactured by a third party and sold under a generic brand.

Domestic vs. overseas manufacturing

Domestic clothing manufacturing refers to the production of clothing within a particular country, while overseas clothing manufacturing refers to the production of clothing in another country.

There are advantages and disadvantages to both domestic and overseas clothing manufacturing. Some advantages of domestic clothing manufacturing include:

- Faster turnaround time: Clothing produced domestically can often be produced more quickly than clothing produced overseas because there are no delays caused by shipping and customs processes.

- Better quality control: Domestic clothing manufacturers have more control over the production process, so they can ensure that the quality of the finished product meets their standards.

- Lower transportation costs: Domestic clothing manufacturers do not have to pay for the shipping costs associated with importing clothing from overseas, which can be expensive.

- Support for the local economy: Domestic clothing manufacturing can create jobs and support the local economy.

On the other hand, some advantages of overseas clothing manufacturing include:

- Lower labor costs: Labor costs are often lower in countries with lower standards of living, which can make overseas manufacturing more cost-effective.

- Access to specialized skills: Some countries may have specialized skills or resources that are not available domestically, which can be advantageous for certain types of clothing production.

- Larger production capacity: Overseas manufacturers may have larger production capacity, which can be beneficial for companies that need to produce large quantities of clothing.

- Access to new markets: Manufacturing overseas can provide access to new markets, which can be important for companies looking to expand globally.

Ultimately, the decision to manufacture clothing domestically or overseas will depend on a variety of factors, including the cost of labor, the quality of the finished product, and the needs of the company.

I recommend producing locally when the order quantity is less than 50pcs for each item. Otherwise, overseas will be your better option.

Ask about their experience

When you’re looking for custom clothing manufacturers, it’s important to ask about their experience! A great way to start is by asking how long they’ve been in business. If a company hasn’t been around for very long, it might be a good idea to keep looking. After all, a reputable company will have a solid track record of working on a variety of designs, have access to all kinds of fabrics, and have many other great qualities that only come with years of experience in the clothing manufacturing business.

You can also ask the supplier to send you some pictures of their previous work! It’s a great way to get a sense of their style and quality. Just make sure to ask for pictures that they’ve taken themselves – not just advertising photos.

It’s important to be aware that some suppliers may not be entirely truthful about their abilities, even if they don’t have experience making the type of clothing you need. For instance, a factory that specializes in t-shirts may not have the ability to make high-quality jeans. That’s why it’s crucial to check their qualifications and production capacity before moving forward.

In Lezhou, with 19 years experience of in clothing production, we help hundreds of brands make great products. For more pictures of our previous work and some feedback from the brand’s owner, please kindly have a look at our custom case page.

Look at their quality control processes

Quality is key when it comes to custom clothing, so don’t be afraid to ask suppliers how they ensure top-notch quality control throughout the process! You might want to find out if they use any special equipment or techniques, and how they test the product before it’s sent out. And of course, it’s important to know what happens if something does go wrong. By asking these questions, you’ll gain valuable insight into their quality control process and be able to make a more informed decision about whether or not to work with them.

At Lezhougarments, quality is our top priority! That’s why we have a rigorous three-step quality inspection process to make sure every piece of clothing is up to our high standards. We check the fabric quality before cutting, the printing or embroidery quality before sewing, and the finished clothing quality and measurements before packing. This helps us maintain a defect rate of less than 2%, ensuring that you receive the best possible product.

Minimum order quantity

The minimum order quantity is the small number of products you must purchase in one order from a supplier. Suppliers set MOQs to avoid wasting resources on orders that deliver little or no profit. It can be based on the number of units or the total order value.

MOQ of a small factory normally starts from 100pcs or even less.

Medium-size factories accept order quantity more than 300pcs-500pcs for each design.

Large-size factories won’t accept orders of less than 1,000pcs for each design.

How to ship products from China to my country?

Shipping products from China to your country can be done through a variety of methods. Here are some common steps to follow:

Find a reliable freight forwarder or shipping agent in China. You can search online for reputable companies, read reviews and compare rates. You can also ask for referrals from friends or business associates.

Determine the shipping method you want to use. You can choose between air freight, sea freight or express courier. Air freight is the fastest but most expensive option, while sea freight is slower but more economical for larger shipments. Express couriers, such as DHL or FedEx, is the fastest and most convenient for smaller shipments.

Provide your supplier with the shipping information and arrange for them to package and label your products for export. They will need to provide the correct documentation and customs information.

Once your products are ready for shipment, your freight forwarder or shipping agent will handle the transportation and customs clearance on your behalf. They will also provide you with tracking information so you can monitor the progress of your shipment.

When your products arrive in your country, they will need to clear customs. You will need to provide the necessary documentation and pay any applicable duties or taxes.

Tips: Most of the clothing manufacturers in China have some partner shipping agent who can help you arrange shipment and even customs clearance.

How to protect your own fund’s safety and good quality?

Importing clothing from China can be a profitable business, but it also comes with risks, such as the possibility of receiving poor quality or counterfeit products. To protect your funds and ensure good quality clothing, here are some tips to follow:

Find a reputable supplier: Research and identify trustworthy suppliers in China by checking their backgrounds, customer feedback, and certifications. You can also ask for references and speak to other customers to confirm their reliability.

Request samples: Before placing a bulk order, request samples from the supplier to ensure the quality of the clothing. You can evaluate the materials, stitching, and finish to ensure it meets your requirements.

Inspect the products: Once the bulk order is ready, have a third-party inspection company inspects the products to ensure the quality meets your standards. You can also inspect the products yourself or hire a trusted agent in China to do it for you.

Use secure payment methods: Use secure payment methods such as PayPal or credit cards to avoid fraud or disputes. Also, negotiate with your supplier to agree on payment terms that protect your interests.

Know the regulations: Be aware of the regulations regarding clothing importation in your country to ensure you comply with all requirements. This includes labeling, safety standards, and documentation.

By following these tips, you can reduce the risk of receiving poor-quality clothing and protect your funds when importing clothing from China.

How to get a sample from the supplier?

To get a sample from a Chinese clothing manufacturer, you can follow these steps:

Identify potential manufacturers: Look for manufacturers that specialize in the type of clothing you want to produce. You can use online directories or search engines to find manufacturers or attend trade shows and exhibitions to meet suppliers in person.

Contact the manufacturer: Once you have identified a few potential manufacturers, reach out to them and request a sample of their work. You can do this by email, phone, or through their website. Make sure to provide detailed specifications for the sample, including the type of clothing, size, material, and any special features.

Negotiate terms: The manufacturer may charge you for the sample or offer it for free, depending on their policies. Be sure to negotiate the terms of the sample, including the cost, shipping fees, and timeline for delivery.

Review the sample: Once you receive the sample, carefully inspect it to ensure that it meets your specifications and quality standards. If there are any issues, communicate them to the manufacturer and work together to resolve them.

Place an order: If you are satisfied with the sample, you can place an order with the manufacturer for the desired quantity of clothing. Be sure to negotiate the terms of the order, including price, delivery time, and payment methods.

Remember that communication is key when working with a manufacturer, especially when dealing with language and cultural barriers. Be clear and concise in your communication, and be open to compromise and negotiation to ensure a successful partnership.

The more detailed information you provide to suppliers, the better they will be able to produce the samples you expect.

Final words

Finding a trustworthy clothing manufacturer can be tough, but we’re here to make it easy for you! With nineteen years of experience in garment production, we’ve got the skills and know-how to bring your vision to life. And if you’re just starting out, we’ve got you covered – our small MOQ of just 100 pieces per color and design makes it simple to get your business up and running. So if you’re still on the hunt for a reliable factory, look no further! We’ve helped more than a thousand brands succeed with our top-notch products and services, and we’re excited to do the same for you.