Finishing’s significance in the textile industry

A finishing process is a series of treatments applied to textile products to improve their appearance, performance, or “hand” (feel). These processes can be performed on natural and synthetic materials and are typically done after dying the yarn or fabric. Common finishing techniques include bleaching, dyeing, fulling, mercerization, singeing, and flame retardant treatment. By adding value to the product and making it more attractive, functional, and user-friendly, finishing helps to complete the textile manufacturing process.

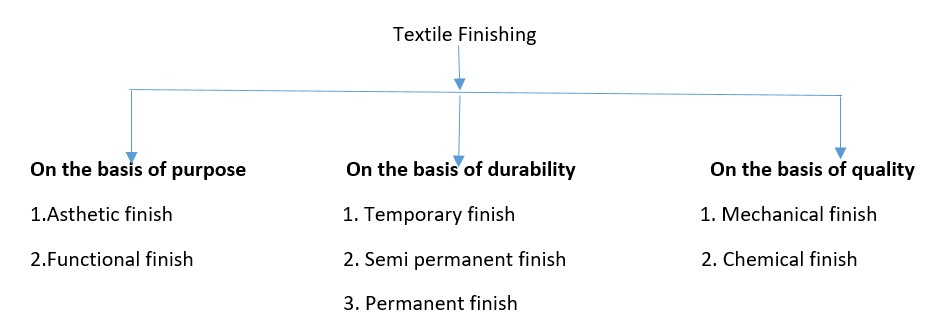

DIFFERENT TYPES OF TEXTILE FINISHES

The development of various finish processes has been prompted by the rising demands for product quality and finishes. However, we’ll just be focusing on fabric durability as a finishing issue here.

TEMPORARY FINISHES FOR TEXTILES

Temporary finishes, on the other hand, are those that wash away when cleaned. The lifespan of these paints is limited to the number of washes. The paste of starches and gum, filling materials, softening chemicals, wetting agents, glazing agents, brightener components, etc., is applied to the cloth to give it this look. It’s the final fabric feel (feel), properties (hardness)

- Softness

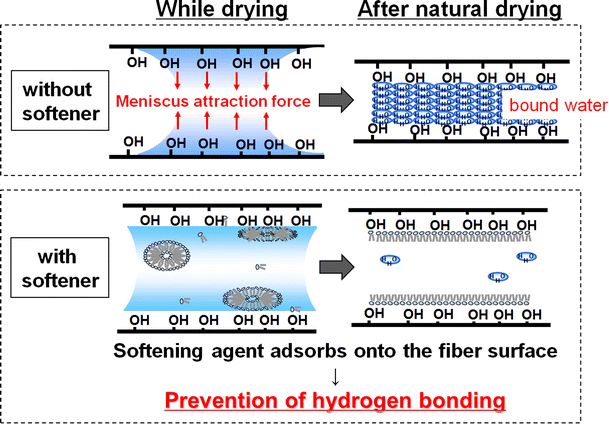

A fabric’s feel is equally as significant as its appearance. Soft, smooth fabric is more pleasant to wear than a stiff, rough one. Fabric softeners are added to the finishing stage of textile production to achieve this desired effect. There are several different fabric softeners, but they all work by lubricating the fabric’s fibres.

This makes them lie flat and gives the fabric a softer feel. In addition, fabric softeners can also give the fabric a glossier appearance. As a result, they are often used on dress shirts and other garments that need to look sharp. Fabric softeners are an essential part of the textile industry, and their use can make a big difference in the quality of a garment.

- Stiffness

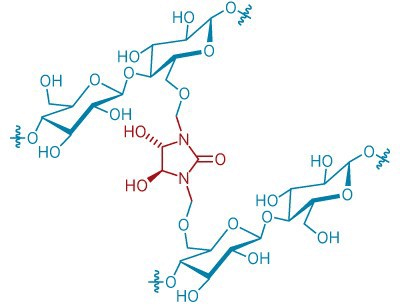

Starches are polysaccharides that consist of large numbers of glucose molecules bonded together. They may be made from a variety of materials, including as wheat, corn, and tapioca. When used in textile manufacturing, starches provide stiffness and body lustre.

In particular, tapioca starch is often used to provide a high-quality finish on fabrics. Maize starch, meanwhile, is commonly used as a sizing agent. It helps to improve the handle of the fabric and prevents creasing.

- Enhance finish

Three types of wiping agents can wet the textile rapidly and enhance the finish. These include cationic, anionic, and non-ionic agents. Cationic agents are attracted to positively charged ions, while anionic agents are attracted to negatively charged ions. Non-ionic agents do not carry a charge. Each type of agent has its own advantages and disadvantages. For example, cationic agents are often more effective at wetting textiles than anionic or non-ionic agents.

However, they can also cause damage to some types of fabrics. Anionic and non-ionic agents are generally safer for delicate fabrics but may not be as effective at wetting textiles as cationic agents. Ultimately, the best wiping agent for use on textiles will depend on the specific fabric being treated.

- Wetting

Wetting agents are used in a variety of industries for a variety of purposes. In the textile industry, they are often used to add weight to the fabric. This can be done by adding wetting agents to the dye bath or impregnating the fabric with wetting agents before dyeing. In addition, wetting agents can also be used for filling purposes.

Examples of wetting agents that can be used for filling include French chalk, china clay, and synthetic softeners. When used for filling, wetting agents help improve the fabric’s smoothness and loft. As a result, they’re frequently combined with additional fillings like down or feathers.

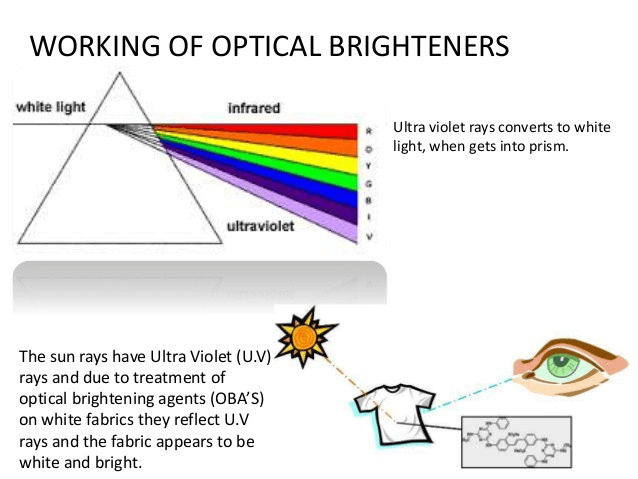

- Brightness

Optical brighteners are added to fabric finishes in the textile industry to create a whiter, brighter appearance. These brighteners absorb ultraviolet light and re-emit it as visible blue light. This compensates for the yellow tint of the fabric foundation, resulting in a more uniform colour.

Optical brighteners are available in various colours, from victoria blue to acid violet. While they are typically used in small quantities, they can greatly impact the finished product. Optical brighteners are an important part of the textile industry, and their use will likely continue to grow.

SEMI-DURABLE FINISHES FOR TEXTILES

Semi-durable finishes are more resistant to washing than temporary finishes, but the average lifespan of this finish still depends on the types used.

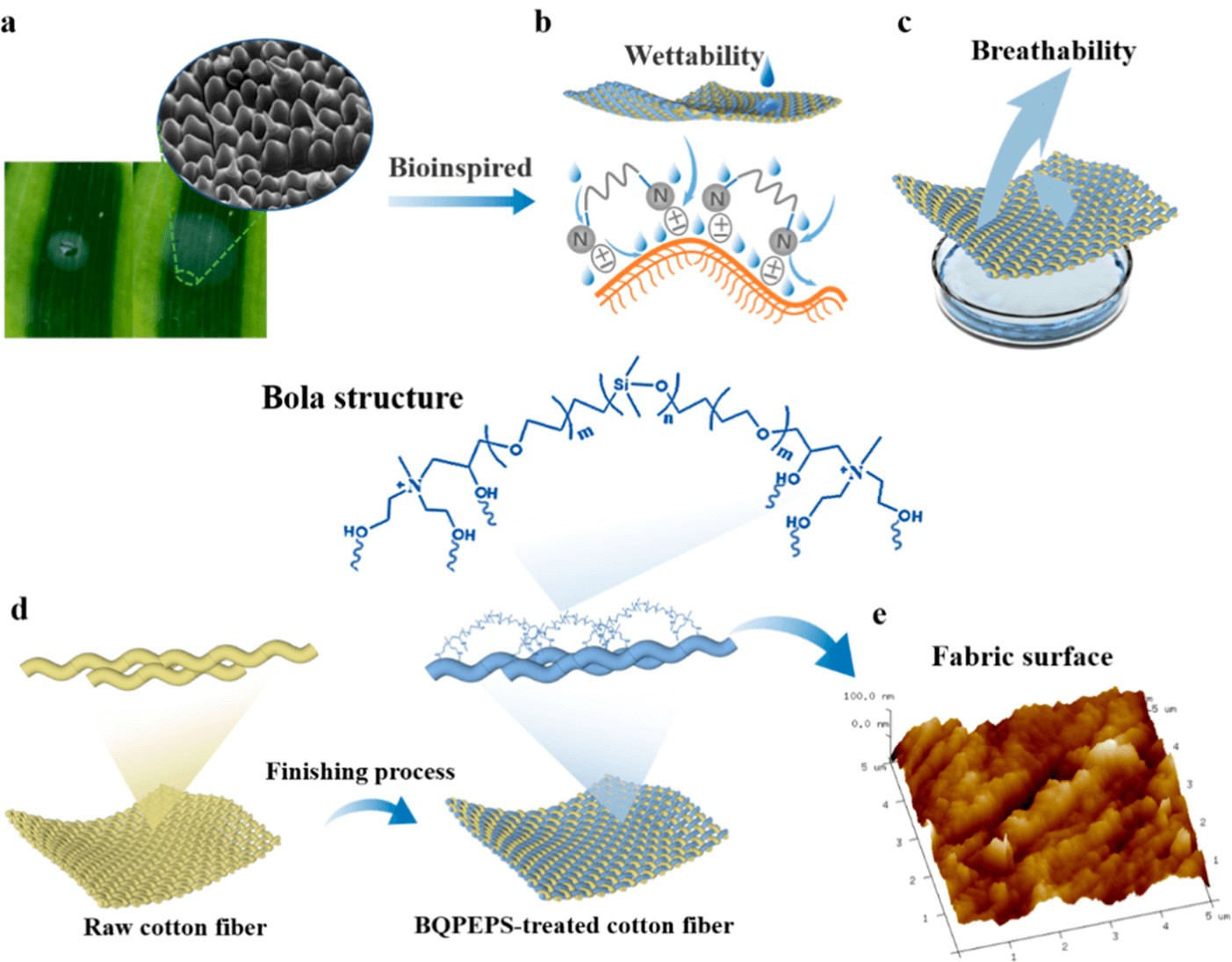

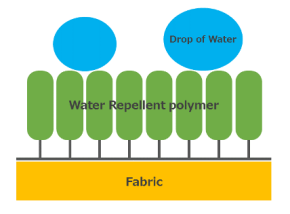

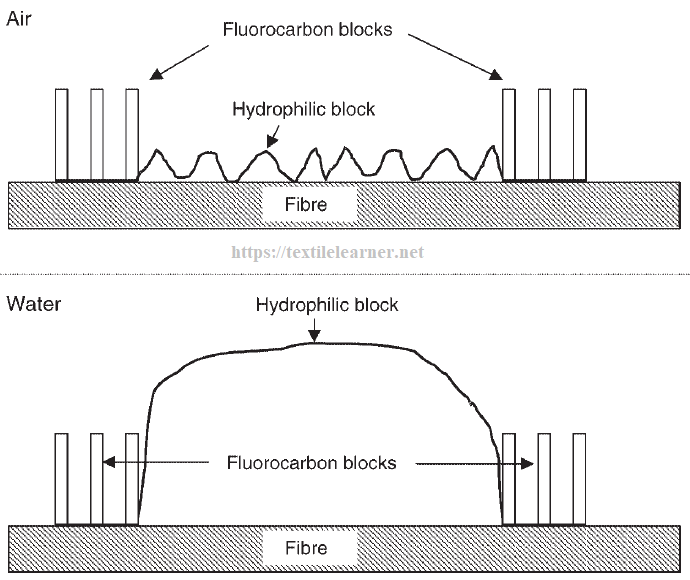

- Water repellent finish

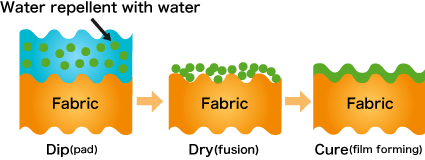

Waterproofing and water repellency are two different concepts that are often confused. Waterproofing is the process of coating fabric with a material that will prevent water from penetrating it. This may be accomplished in a variety of methods, the most common of which is to coat the cloth with a polymer such as PVC or polyurethane.

On the other hand, water repellency is the fabric’s ability to resist wetting. This may be performed in a variety of ways, the most frequent of which is to treat the cloth with a water-repellent coating.

Water-repellent finishes are usually applied to fabrics using a pad-dry-cure method. The cloth is initially soaked with a finishing chemical solution before being run through a pair of rollers to remove surplus liquid. The fabric is then cured, typically by exposure to heat or ultraviolet light. This process creates a durable water-repellent finish that helps to keep fabrics dry and resist staining. Fluorochemical finishes are also available, which, in addition to being water repellent, also provide oil repellency. These finishes are often used on garments such as raincoats and ski jackets.

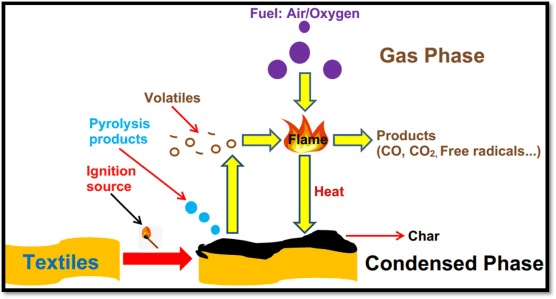

- Flame proofing:

Burning is a physical process involving releasing energy in the form of heat and light. When a fabric is exposed to flame, the heat causes the fibres to break down and release their energy. The resulting light is what we see as flames. To slow down this process, textile fabrics can be given a temporary flame-resistant finish by immersing them in a water solution of borax and boric acid or a mixture of boric acid, di-ammonium phosphate, sulphamic acid, etc.

However, this treatment must be applied after every wash to be effective. For a more durable finish, chemical treatment can be used, which fuses with the fibres and alters the fabric’s properties, making it stiffer. This slows the burning process and makes the fabric less likely to catch fire.

- Soil release finish:

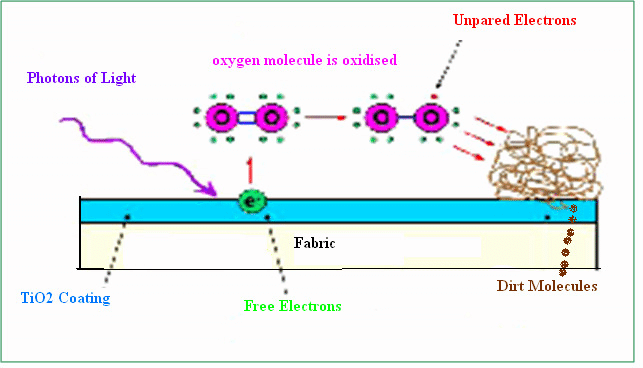

Soil-release finishes are applied to textile materials to create a fabric resistant to soiling and staining. This type of finish typically includes soil resistance, soil release, and anti-soil redeposition properties. Soil-release finishes are often applied to synthetic fabrics such as polyester, nylon, and acrylic.

The soil release finish allows the fabric to shed the soil gathered during normal washing and further stop redeposition onto the fabric. The soil release finish is typically a clear or white finish that does not alter the appearance of the fabric. The finish is usually compatible with all dyes and can be applied by various methods, including padding, roller coating, spraying, and transfer printing.

- Mothproof:

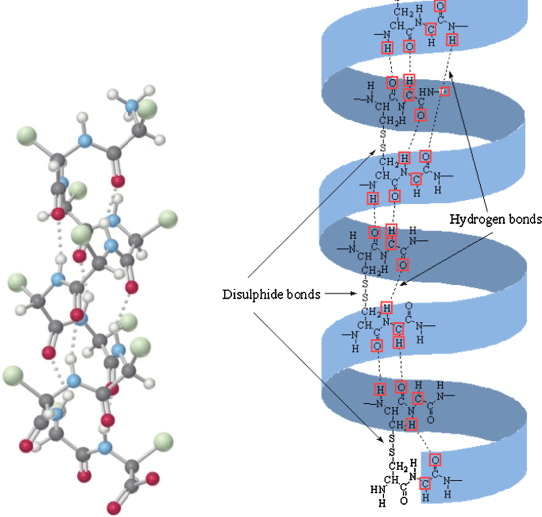

Wool is a popular choice for clothing and upholstery, but it is also one of the most susceptible fabrics to damage from moths. Moth larvae feed on wool fibres, causing holes and damage that can ruin a garment or piece of furniture.

Closed packing, cold storage, hot ironing with superheated steam, contact poison such as fluorides and silica, and potent volatile chemicals such as naphthalene balls or para-dichlor-benzene are all strategies for preserving wool from moth damage.

In addition, treating the fabric with a semi-durable finish that impregnates the fibres with non-volatile substances can also help to prevent moth damage. Taking these precautions ensures that your woollen items will look their best for years to come.

DURABLE FINISHES FOR TEXTILES

The term “durable” describes finishes resistant to washes and can survive longer washing cycles if not for their lifetimes. It’s mostly done by changing the fibre’s characteristics to reduce faults in the cloth, whether natural or manufactured.

Anti-shrink finish

When you buy a new shirt, the last thing you want is for it to shrink after the first wash. Unfortunately, that’s often exactly what happens – unless the fabric has been treated with an anti-shrink finish.

This treatment is typically applied to cotton or cotton blends and helps prevent the fabric from shrinking during washing. The process was first developed by Cluett Paybody and Co., who patented the technique under “sanforized fabric.”

The fabric is mechanically shrunk between drums and rubber belts as it travels through a stenter machine in this procedure. This stabilizes the cloth, preventing it from shrinking further, especially while washing.As a result, shirts treated with an anti-shrink finish are less likely to develop wrinkles or become misshapen after washing.

Resin finish:

Because of their versatility and capacity to give a variety of benefits, resin treatments are one of the most popular fabric finishes.

- Resin finishes can impart sharp crease retention and dry/wet crease recovery, making them ideal for use in garments that require a crisp, professional look.

- They can also be used to provide wash-and-wear functionality, making it easy to care for your clothes without sacrificing style.

- In addition, resin finishes are also highly durable, meaning they will withstand repeated washings and wearings without losing their shape or efficacy.