Since the early days of society, clothing has been an essential part of human culture. Throughout the years, the methods and materials used for making clothes have changed dramatically, but one thing has remained constant: the need for custom clothing. But what should you know before taking your clothes to be custom-made? Keep reading for A Complete Custom Clothing Manufacturing Guide!

What is clothing manufacturing?

The process of creating clothing and other textile products is called clothing manufacturing. It involves many steps, like cutting fabric, sewing it together, and adding final touches. Each step in making a garment is considered its sub-operation.

The way these operations are carried out changes based on the machines available, clothing production method used, and worker skillset.

How does the apparel clothing manufacturing business work?

A complete custom clothing manufacturing workflow should include the following:

- Design: Fashion designers attempt to design practical and attractive clothing.

- Purchasing: Materials are purchased from different overseas clothing suppliers individually.

- Sampling: Samples are provided at different stages of the production development process.

- Manufacturing and Quality Control:

- Testing: The seven steps of clothing inspection

- Packaging: Packaging is a coordinated system for preparing goods for transportation, storage, logistics, and sales.

- Shipping: Offshore or DDP pricing custom clothing services

Design

Designers begin by trying to create clothing that is both practical and attractive. They consider who might wear the clothes and the situation in which they would be worn. For example, they might design a pair of jeans that would be suitable for casual wear or a dress that would be appropriate for a formal occasion.

Once they know what they want to create, designers sketch their designs and choose the fabrics and other materials used to make the clothing.

Sketches

The first step to creating a fashionable figure is through a croquis. A sketch is a quick guide for the proportions of a fashion figure. A croquis is like a paper doll; it’s s a template that can be placed under a piece of paper to draw clothing on. Most fashion figure drawings start with a 9-head scale, but sometimes an 8-head scale is used, especially when more clothing needs to be shown. Find a free downloadable croquis template and start creating your fashion figure drawings!

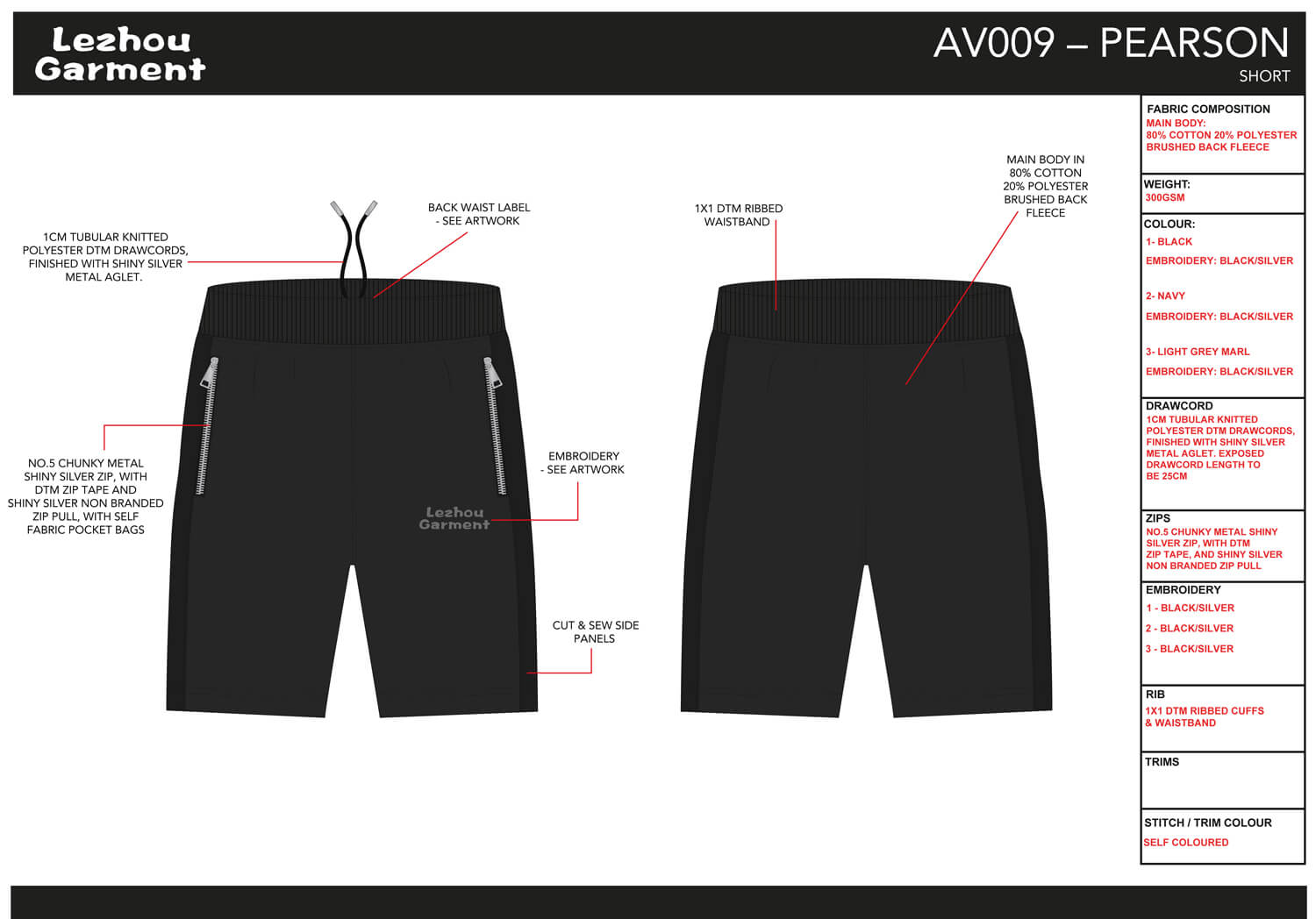

Tech-pack

A tech pack, also known as a spec sheet, is a set of files created by a designer to explain their design to the best clothing manufacturer so that they can translate that information into a finished garment.

A tech pack usually contains detailed illustrations or sketches of the garment and all of the measurements and specifications required to make the garment. The goal of a tech pack is to ensure that the best clothing manufacturer understands the designer’s vision for the garment and can produce it accordingly.

A well-made tech pack can mean the difference between a cheap garment and one that looks high quality. Designers must take the time to create accurate and comprehensive tech packs to avoid any misunderstandings or miscommunications with the manufacturing team.

By creating a tech-pack, designers can help ensure that their garments are made to the highest standards and meet their vision.

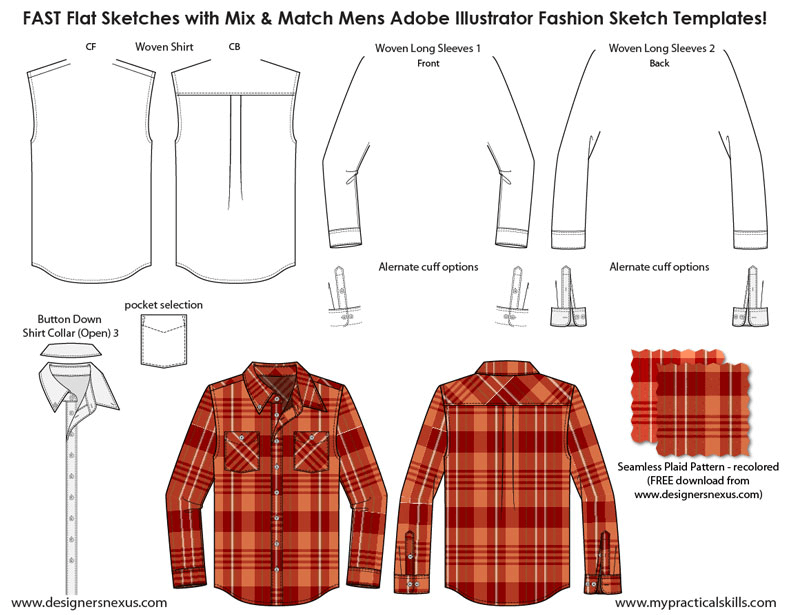

CAD files

CAD files are an important part of custom clothing production. CAD technology is used in the design and development process to reduce the need for traditional hand-sketched illustrations.

This is extremely important for fashion sketches, flat drawings, pattern development, garment construction of production planning, and many other aspects of fashion design.

CAD files provide a more accurate representation of how a particular garment will look when finished. This is especially important for complex garments with intricate details. CAD files can be shared easily with other design team members, which helps streamline the development process.

In addition, CAD files can be used to create virtual samples of garments. This is a valuable tool for testing different design options and ensuring that all details are accounted for before production begins.

How do designers and clothing manufacturers collaborate on clothing lines?

Purchasing

To finalize your project, you must find OEM clothing manufacturers that are appropriate for your needs. You can either develop a clothing business relationship with an all-inclusive clothing manufacturer or select different materials from many high quality clothing manufacturers piecemeal.

Fabrics

Choose the right fabric supplier before beginning your project. The table below outlines different fabrics, their constructions, compositions and weights.

- Cotton: cotton bari yarn, cotton linen, cotton poplin, cotton twill, cotton satin, cotton crepe, cotton reversible, cotton canvas, cotton dobby, cotton denim, cotton lycra denim, cotton silk, cotton viscose

- Viscose: viscose crepe, viscose dobby, viscose crepe dobby, viscose satin, viscose georgette

- Modal: modal twill, modal satin, modal dobby, modal crepe, modal crepe dobby

- Hemp

- Linen

- Hand-spun, hand-woven

- Tencel twill, Tencel denim

- Baby cord, corduroy

- Silk, etc.

Dyeing

The dyeing clothing manufacturing process is an essential part of clothing production. During the dyeing process, the dye interacts with the fiber while simultaneously being absorbed and diffusing into the fibers. This process allows the fabric’s color to be evenly distributed and can also improve the colorfastness of the fabric.

However, it is important to note that not all dyes are compatible with all fibers. For example, some dyes may not be suitable for synthetic fibers. As a result, it is important to select the appropriate dye for the fabric being dyed.

Trim

Fabric trims, also known as garment accessories, are materials added to clothing items that improve the style. These can include threads, buttons, linings, beads, zippers, patterns or patches.

Labels

There may be the following types of clothing labels.

- Brand or main label: The brand label is the most important part of a product, as it determines the name or logo of the clothing company. This label often stands for quality, durability and how good the product makes you feel.

- Size label: A size label indicates a set of specific body measurements, usually printed asa letter.

- Care Label: The care label exists to provide consumers with guidance on how best to wash, dry, and iron their private label clothing to maintain the vibrancy of colors, protect designs from fading or bleeding, and prevent shrinking.

- Flag label: A logo label is a small decoration on the outside of clothing that usually contains the brand’s logo. These labels are often used as design elements to make clothing more visually appealing.

Sampling

In any bulk garment production process, sampling is an essential step to ensure that the final product meets quality standards. By taking small samples at different stages of efficient production, overseas clothing manufacturers can check for defects and make corrections before mass apparel production begins.

Prototype

It would help if you always created a prototype of your clothing design before moving on to the final product. This lets you see how the garment looks and fits and make any necessary changes. The prototype is often made from different fabrics and trimmings than what will be used in the end because those materials are usually unavailable.

Fit sample

A fit sample’s main purpose is to check a garment’s fit and construction. A fit sample is created by taking actual measurements of the garment based on the original product and specifications provided by the buyer. This allows for any necessary adjustments to be made to the pattern or design before mass production begins.

Pre-production/ Gold seal sample

The garment’s final sample is called the pre-production or gold seal sample. We make this one using the original fabric and all original trims and embroidery or print (if applicable). But we won’t start making a bunch of them until the PP sample gets approved by our client.

The PP sample is a significant step in the garment manufacturing process, as it allows the client to see and touch the final product before mass production begins. It is also an opportunity for the client to request changes they may want to see in the final garment. Once the PP sample is approved, the garment can then move on to bulk production.

Shipment sample

Some garments are selected from the final shipping lot and sent to the buyer as shipping samples. The purpose of sending samples is to assure the buyer that the quality will remain the same throughout the end of production. This means that if the clothing manufacturer encounters any problems during the whole manufacturing process, they will respond and correct them immediately.

Once the samples are approved (i.e., the buyer deems them acceptable for the final order), production of the final order will begin shortly. However, if samples receive an unfavorable evaluation (e.g., wrong size or color, poor quality), modern garment manufacturers must improve their process until the samples are approved.

Manufacturing and Quality Control

Production orders cannot begin until the design has been approved and the technical package is completed. Then, the designer must determine factors such as quantity, size and color assortment. Other important details at this stage include their order’s quotation and estimated shipping date.

Fabric Inspection

Production can’t start until the fabric is checked for any issues, such as weave or dye defects, color fading, shrinking in size, and variations between different batches. Once these potential problems are identified, the necessary steps must be taken to correct them.

Spreading, Form Layout and Cutting

Once a fabric has been checked, it is moved to the spreading and cutting area in a garment manufacturing facility. In preparation for the cutting process, the fabric is laid out by hand or using a computer-controlled system on tables.

The person performing the spreading and cutting operation, known as the marker-maker, first creates a paper template, or marker, of the various sizes that need to be cut from the fabric. Once the marker is created, it is placed over the fabric so that the cutter can follow the lines on the marker to cut out the individual pieces.

The cutting process is usually done by machine, although some smaller garments may still be cut by hand. After the pieces have been cut out, they are moved to the sewing area, where they will be assembled into the finished garment.

Spreading, form layout and cutting are important steps in the garment manufacturing process, as they determine how all the fabric pieces will be used in the final product.

Embroidery, Screen Printing and Decoration

Off-site facilities usually handle embroidery, screen printing, and decoration because these processes can only occur when directly specified by the customer.

Most of the time, the design team will work with these facilities to ensure that their vision is executed flawlessly on the final product.

Sewing

Cut and sew the fabric together according to the size, color, and quantity determined by the sewing room.

- The fundamental process of garment manufacturing is connecting different parts.

- We custom-sew each project to the buyer’s specifications.

- Sewing machines vary in design and function, from general stitching to specialized machines for fusing collars, buttons, and buttonholes.

Testing

A third-party inspection is an important part of many clothing import supply chains. By working with an independent, unbiased third party, clothing retailers and apparel manufacturers can ensure that their products meet all quality and safety standards.

Measuring clothing size

Garments that do not meet the consumer’s expectations are often returned, costing you money in terms of unsold inventory. Additionally, if this phenomenon persists, it could cause long-term damage to your brand as customers may switch to a competitor with better quality control.

Checking the function of covers, buttons and other accessories

- Tensile test: To confirm that the accessory is securely fastened to the garment, pull on it with a tensiometer for 10 seconds.

- Fatigue test: To test the accessory, quickly use it as expected fifty times (e.g., buckle and unbuckle 50 times), then check that it still works properly and that the garment is not damaged.

- Stretch Test: To achieve the right level of elasticity, stretch both the elastic band and straps. Also, check for any breaks in the elastic fibers or stitching.

Testing fabrics for compliance with quality standards

Fabric quality is a primary factor in the marketability of your product. Poor input material will result in substandard output. By testing products physically and in a laboratory, you can rest assured that they comply with your established quality standards.

Fabric GSM Check

Individuals can perform a GSM inspection with hardly any training or equipment needed. During the inspection, quality control personnel use a GSM cutter to cut out a round piece of fabric from the sample provided and weigh it using an electronic balance. They then compare the recorded GSM against the customer’s specifications.

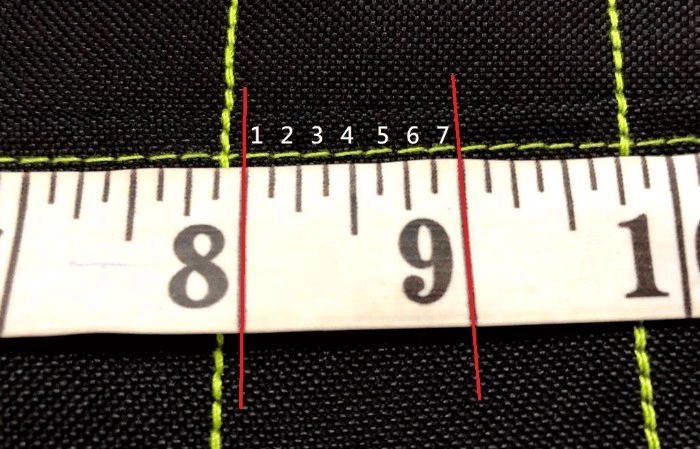

Stitches Per Inch (SPI) Inspection

The quality control inspector checks the number of stitches per inch (SPI), counting the stitches in one selected area within an inch. The SPI inspection only requires a tape measure and good lighting, making it easy to do. Usually, inspecting two SPIs of each style in a shipment is enough.

Material composition inspection

Although you can detect some differences in fabric compositions just by touch, most apparel importers require material composition testing to be certain. Nonetheless, this testing can only be conducted in a qualified laboratory with proper equipment and controls.

Quality Defects and Severity Reporting

Common defects that apparel importers may face include

- Threads that are not trimmed neatly

- Shading discrepancies between various pieces of the same style or sections of the same piece.

- A sewing needle that has come loose from its thread.

Packing

The process of packaging can be time-consuming, but it is necessary to ensure that your products are protected and easy to ship. After a final inspection and folding of the garments, they are sorted by color, size, and style. They are then placed in cardboard boxes that have been clearly labeled with all relevant information.

Garment packing order

- The clothes are packed into polyethylene bags after they have been folded.

- Make sure to confirm the position of stickers and other labels when packing.

- Plastic packaging is sorted by size and color onto racks.

- After the garments are sorted by size and color, they are placed in inner boxes.

- “Assorting” is when you pack an inner box according to the work order.

- A set amount of inner boxes, called cartooning, go inside the carton to complete the packaging process.

- Next, the carton is sealed.

- The carton has several pieces of information listed, including the carton number, size, markings, and destination.

Verifying proper packaging and labeling

Verifying that garments are properly packaged and labeled during final inspections is crucial. This guarantees that the clothes arrive at their destination in the same condition as when they left the facility of the clothing supplier.

Shipment

The following are the ways you can arrange for your goods to be delivered:

FOB

FOB, or Free On Board, is the most common shipping agreement used in exporting garments. As the name suggests, the seller is responsible for the goods until they are loaded onto the buyer’s designated vessel/plane once the goods are on board, responsibility shifts to the buyer.

CIF

CIF (Cost, Insurance, and Freight) is a shipping agreement where the seller agrees to pay for the transportation costs and takes out an insurance policy in the buyer’s name. Once goods are loaded onto a ship or plane, the risk of loss is transferred to the buyer.

Wrapping up

To recap, here are the key things to remember when manufacturing garments:

- Work with a reputable overseas clothing supplier that has experience in your type of product.

- Get samples of your product made before production begins to ensure that the finished product meets your standards.

- Inspect the garments during and after production to catch any defects.

- Properly package and label the garments to avoid any damage during shipment.

- Choose the right shipping agreement for your needs.

By following these steps, you can be sure that your garments will be of high quality and meet your fashion brands expectations.

10 Responses

Good post! We will be linking to this particularly great post on our site. Keep up the great writing

Thanks dear, enjoy reading!

Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated

Hey 🙂 Thanks and hope you enjoy reading.

Nice post. I learn something totally new and challenging on websites

Thank you 🙂

I’m often to blogging and i really appreciate your content. The article has actually peaks my interest. I’m going to bookmark your web site and maintain checking for brand spanking new information.

Hi Vein, thanks. Enjoy reading 🙂

I just like the helpful information you provide in your articles

Thank you 🙂